Gas turbine combustor

A gas turbine and burner technology, applied in the direction of gas turbine devices, combustion chambers, combustion methods, etc., can solve the problems of increased pressure loss, complex support methods, etc., and achieve the effects of easy bending, NOx reduction, and more disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

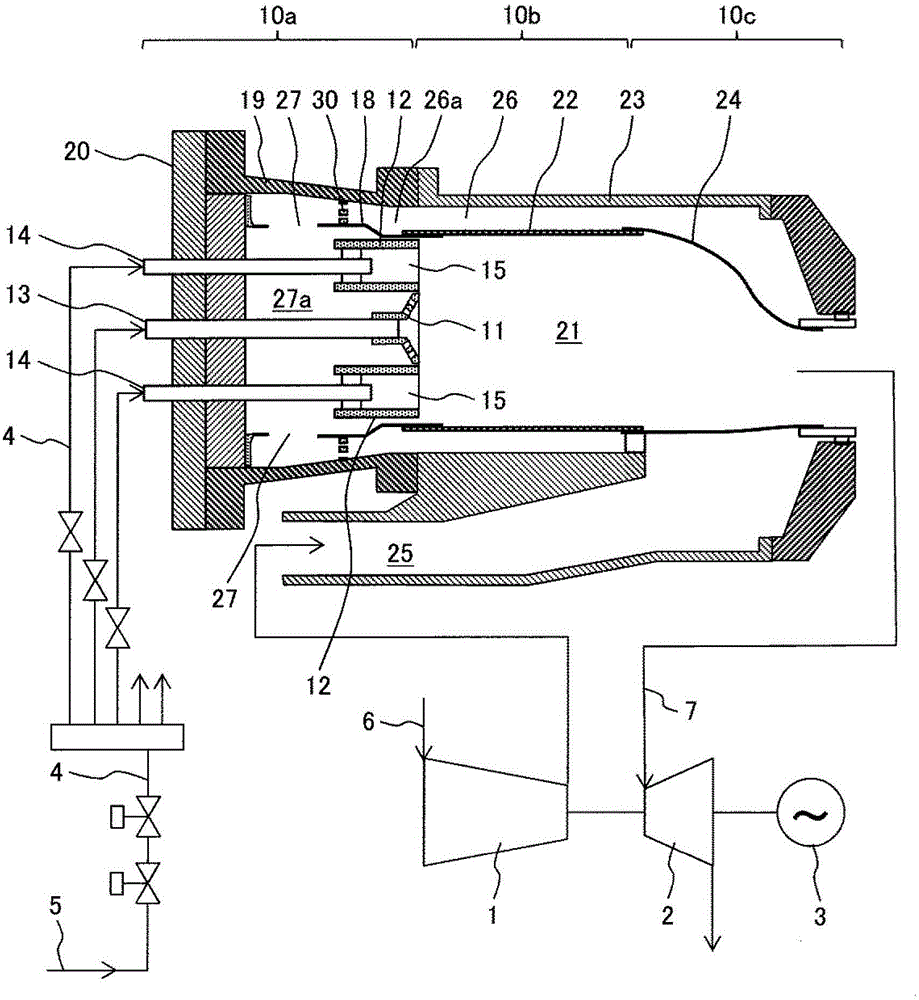

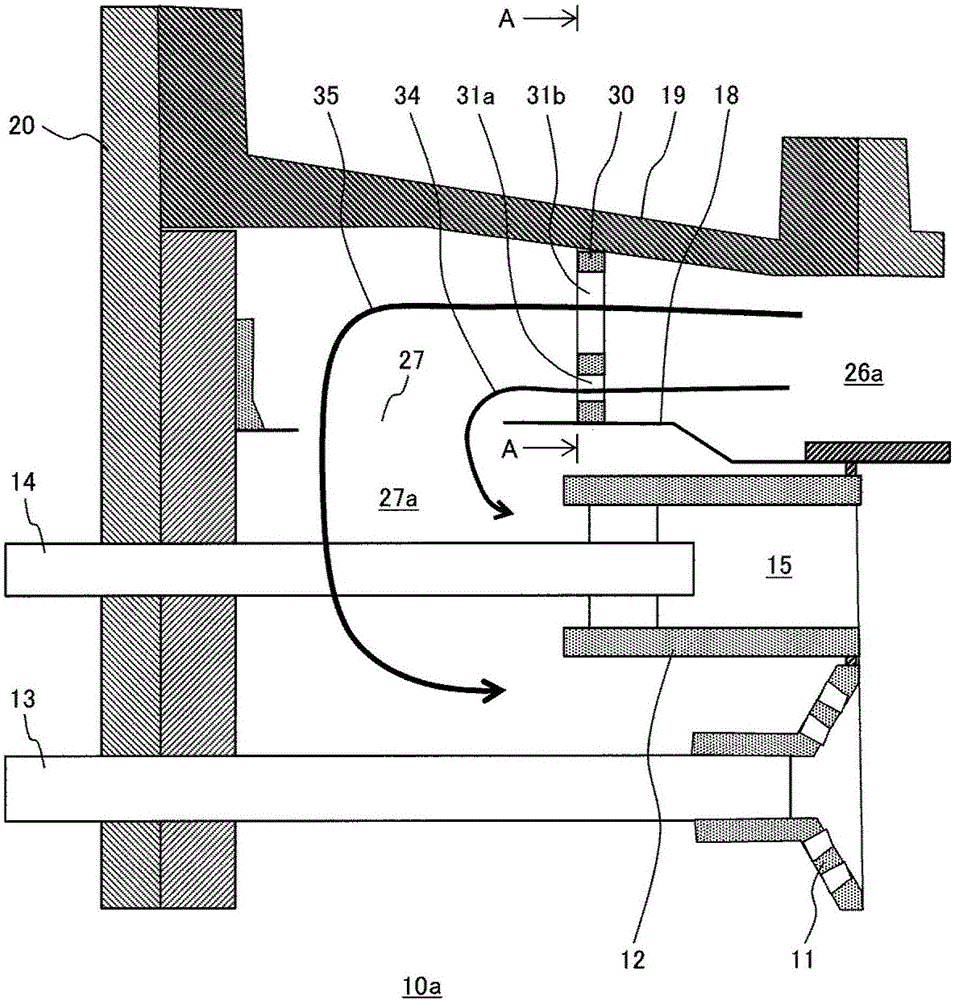

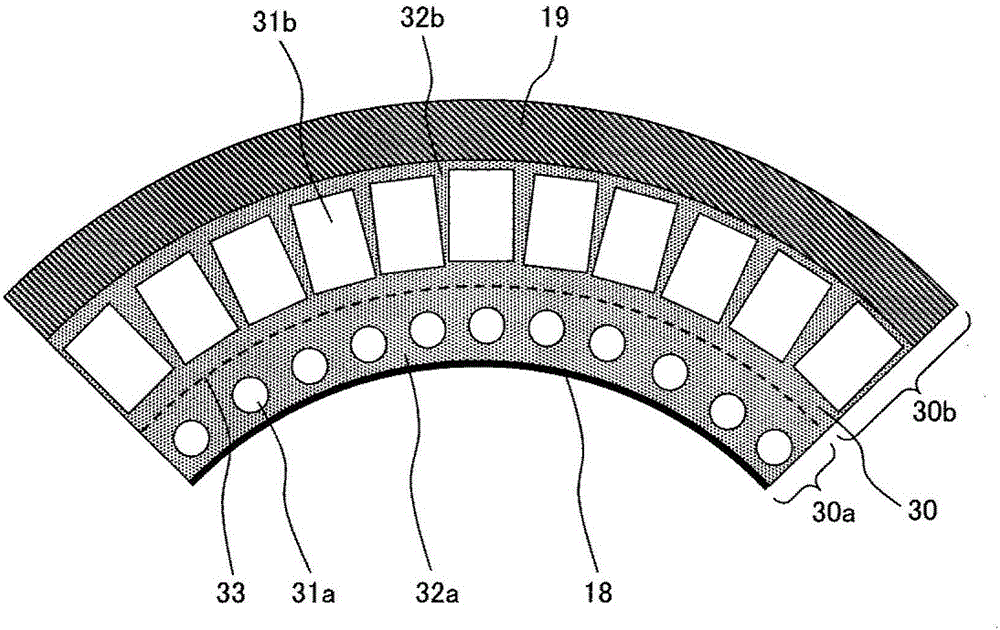

[0041] use figure 1 ~ FIG. 6, the gas turbine combustor according to the first embodiment of the present invention will be described.

[0042] figure 1 A sectional view showing a gas turbine combustor 10 according to a first embodiment of the present invention.

[0043] figure 2 will be figure 1 The shown partial cross-sectional view is enlarged and shows a part of the air flow path of the gas turbine combustor 10 according to the first embodiment of the present invention.

[0044] image 3 Indicates the shape of the obstacle of the gas turbine combustor according to the first embodiment of the present invention provided in the air flow path, figure 2 A view from direction A-A.

[0045] for figure 1 The shown gas turbine generator equipped with the gas turbine combustor 10 according to the first embodiment of the present invention constitutes the gas turbine generator by the following parts: a compressor 1 which acquires combustion air 6 and compresses it; a gas turbi...

Embodiment 2

[0114] use Figure 4 and Figure 5 A gas turbine combustor 10 according to a second embodiment of the present invention will be described.

[0115] Figure 4 It is an enlarged cross-sectional view showing a part of the air flow path 26 of the gas turbine combustor 10 according to the second embodiment of the present invention.

[0116] Figure 5 It shows the shape of the obstacle 50 provided in the air flow path 26a of the gas turbine combustor 10 according to the second embodiment of the present invention. Figure 4 A view from direction A-A.

[0117] Figure 4 and Figure 5 The shown basic structure of the gas turbine combustor 10 according to the second embodiment of the present invention is substantially the same as that of the gas turbine combustor 10 according to the first embodiment, and therefore description thereof will be omitted.

[0118] In the gas turbine combustor 10 of the second embodiment of the present invention, the difference from the gas turbine com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com