Heat accumulating type cooling tower and operational control method thereof

A technology for operation control and cooling towers, which is applied in the fields of regenerative cooling towers, direct heat exchange cooling towers, single-tower multi-group regenerative cycle switching operations, and can solve the problem of pipeline system and cooling equipment corrosion and increased circulating water Corrosiveness, bacteria and algae growth, etc., to achieve energy-saving water resistance, reduce latent heat evaporation loss, and eliminate pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

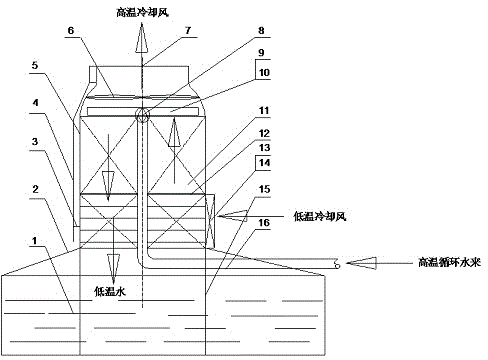

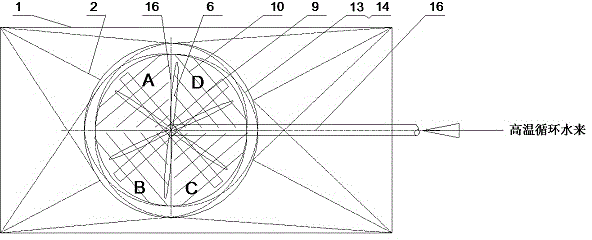

[0022] Such as figure 1 , figure 2As shown, a heat storage cooling tower includes a pool 1, a cooling tower, a tower tube 7 and a circulating water return pipe 15, and the cooling tower is supported on the pool 1 by tower legs 14. Generally, the pool below the cooling tower is It is a water receiving pool. Pool 1 collects the water flowing down from the cooling tower and then sends it to the circulating pool (tank) for cleaning and maintenance of the circulating pool. When the closed structure is formed, the pool (tank) can be fully The closed structure prevents the intrusion of sand and dust in the air, reduces the scaling of heat exchange equipment, can effectively improve the cooling heat exchange efficiency of circulating water, reduce equipment wear and the use of scale inhibitors; the cooling tower on the pool is composed of tower body It is composed of a tower tube, connected to the tower tube 7, and uses the chimney effect of the tower tube to discharge the hot air a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com