A kind of performance detection and analysis method of gas turbine intake filter

A technology of air intake filter and gas turbine, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., and can solve the problem of excessive air intake pressure loss of gas turbines, affecting the safety and economy of gas turbine power plant operations, and the non-compliance of units. Problems such as normal shutdown to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as figure 1 As shown, the present embodiment provides a performance detection and analysis method of a gas turbine air intake filter, which uses a comparison test system of a gas turbine air intake filter system to test the performance parameters of the air intake filter, and the comparison of the gas turbine air intake filter system The test system includes a plurality of test channels, the test channels are composed of intake filters and induced draft fans arranged in sequence according to the air flow direction, and the method includes the following steps:

[0036] S1: Data Acquisition

[0037]Utilize the first pressure measuring gauge to simultaneously measure the air pressure at the air inlet of each of the air intake filters within a plurality of time periods, and obtain the air pressure at each time point in different time periods. The air pressure value at the air inlet of the air intake filter is recorded as the first air pressure value; at the same time,...

Embodiment 2

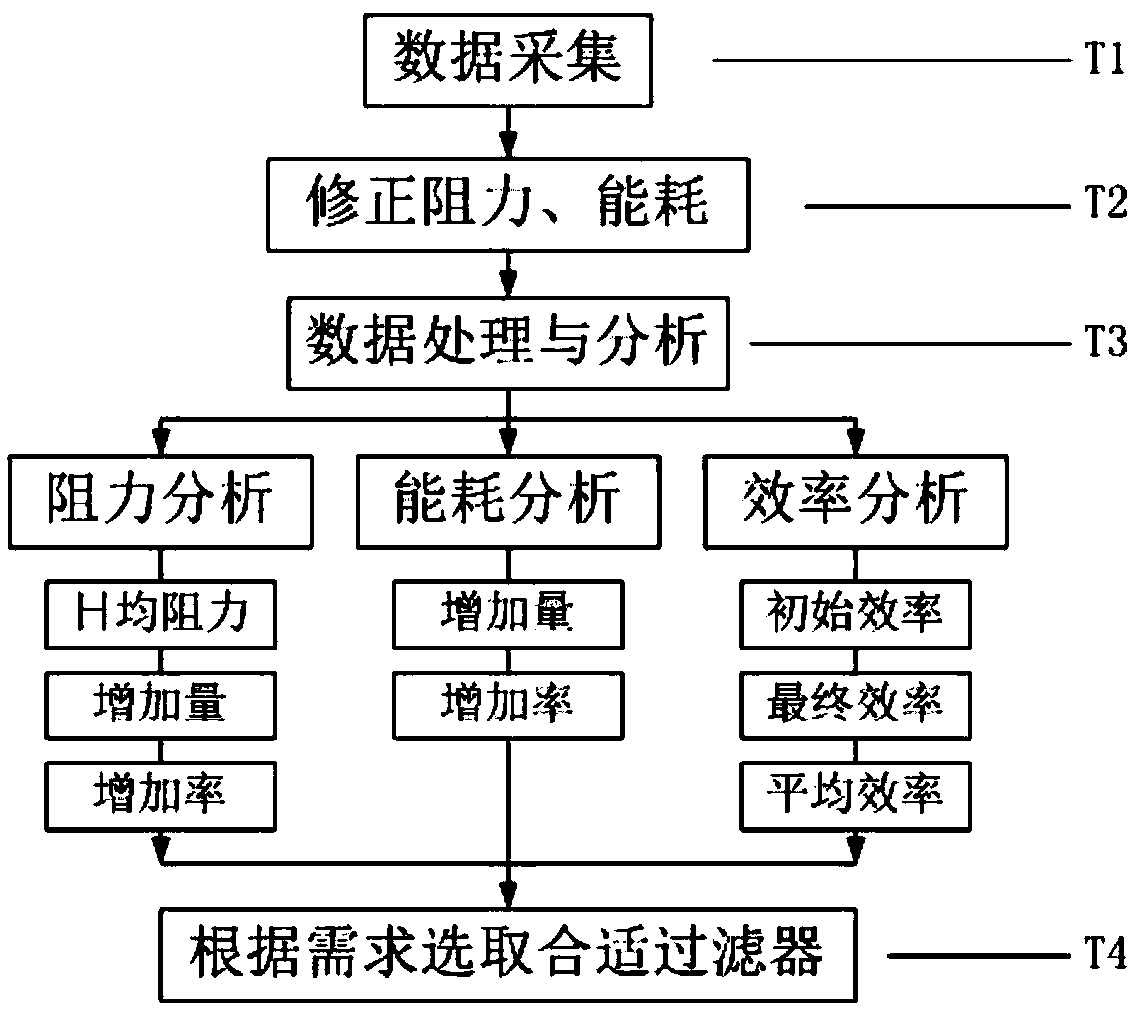

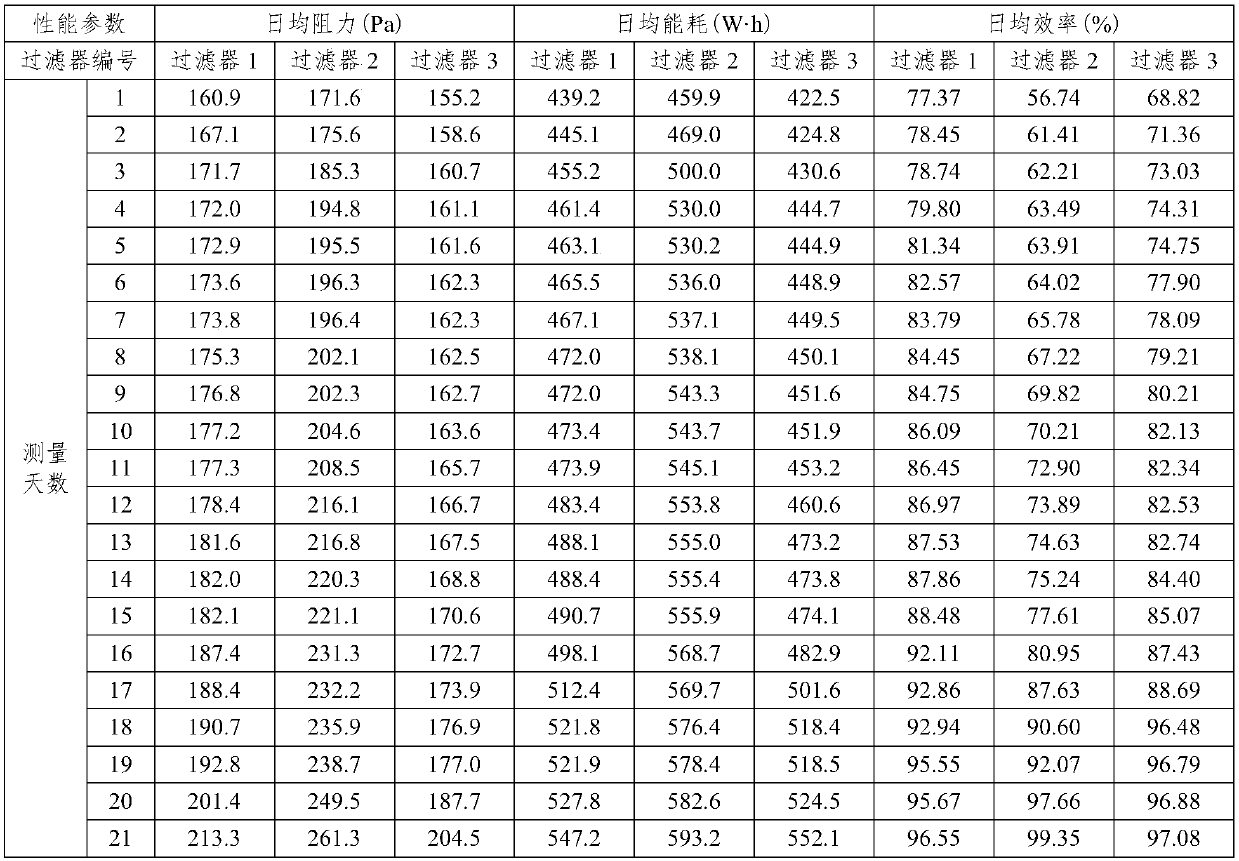

[0048] Such as figure 2 As shown, the present embodiment provides a preferred gas turbine air intake filter performance detection and analysis method, which specifically includes the following steps:

[0049] T1: Data Acquisition

[0050] Collect data according to the process of step S1 described in the first embodiment, and obtain the first air pressure value, the second air pressure value, the air flow value, the operating power value of the induced draft fan, the first air particle number and the second particle count.

[0051] T2: Corrected resistance and energy consumption

[0052] According to the step S2 described in the first embodiment, the resistance of each air intake filter is corrected according to the measured first air pressure value, the second air pressure value and the air flow value, and the corrected progress is obtained. The resistance of the air filter and the correction formula of the resistance of the air intake filter have been described in Embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com