Method for on line monitoring air pressure and automatically replenishing air for transformer

A technology of automatic gas supply and gas pressure, applied in fluid pressure control, electric fluid pressure control, instruments, etc., can solve the problem that transformers, engineering escorts cannot obtain monitoring information in real time, and do not have real-time storage and transportation status information. Display, real-time upload, real-time alarm, real-time release and other issues, to achieve the effect of reliable transportation and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

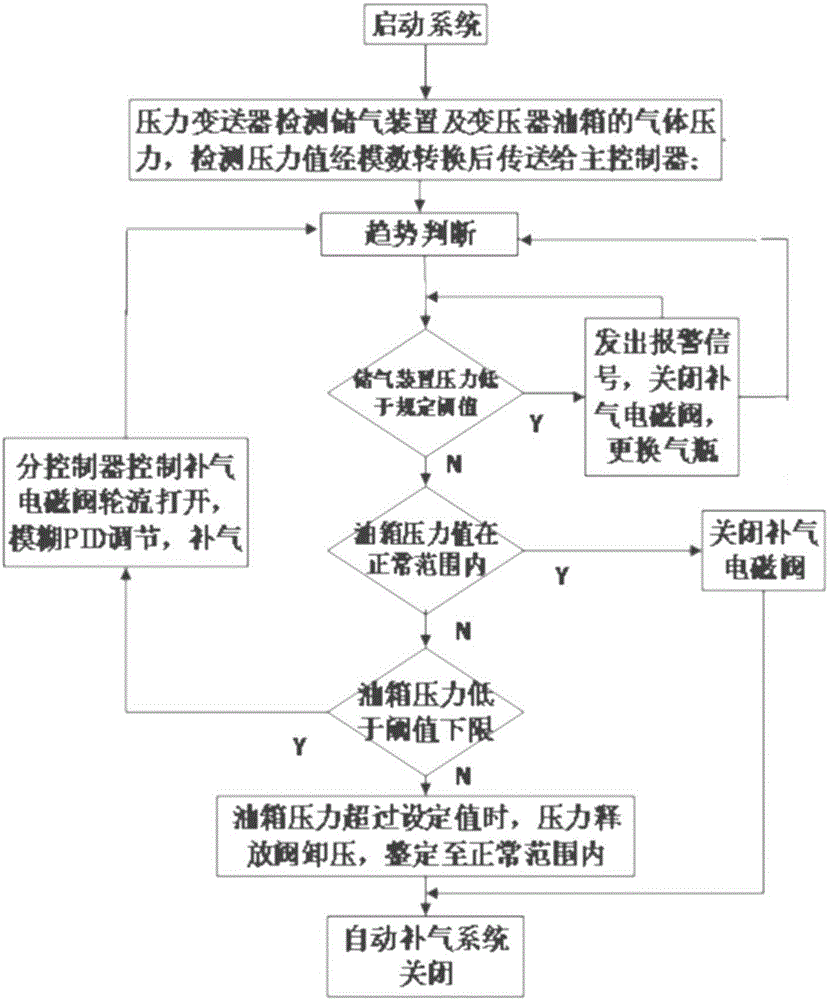

[0026] A method for on-line monitoring of gas pressure and automatic gas supply for transformers, such as figure 1 shown, including the following steps:

[0027] Step 1. After the automatic gas supply system is started, the pressure transmitter detects the gas pressure of the high-pressure gas cylinder and the transformer oil tank. The detected pressure value is uploaded to the sub-controller after analog-to-digital conversion, and the sub-controller transmits it to the main controller through ZIGBEE. controller;

[0028] Step 2, the main controller judges whether the pressure value in the high-pressure gas cylinder is lower than 1.6 MPa, if so, go to step 3, if not, go to step 4;

[0029] Step 3. The main controller sends out an alarm signal, controls the sub-controller to close the gas supply solenoid valve and prompts to replace the gas storage device in time, and opens the gas supply solenoid valve after replacing the gas storage device and returns to step 2;

[0030] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com