Motor

A technology of electric motor and frame, applied in the field of improvement of heat dissipation structure, can solve the problem that the electric motor is difficult to meet the requirements of the market and users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

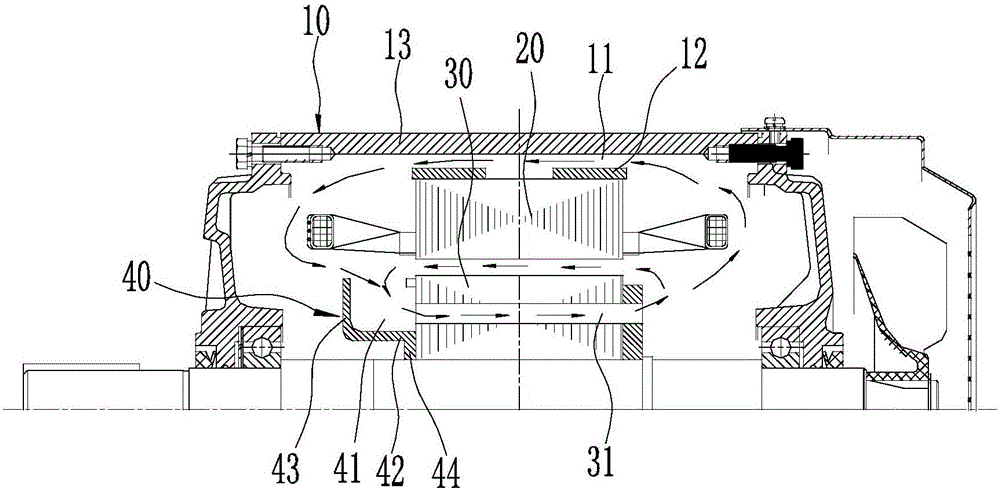

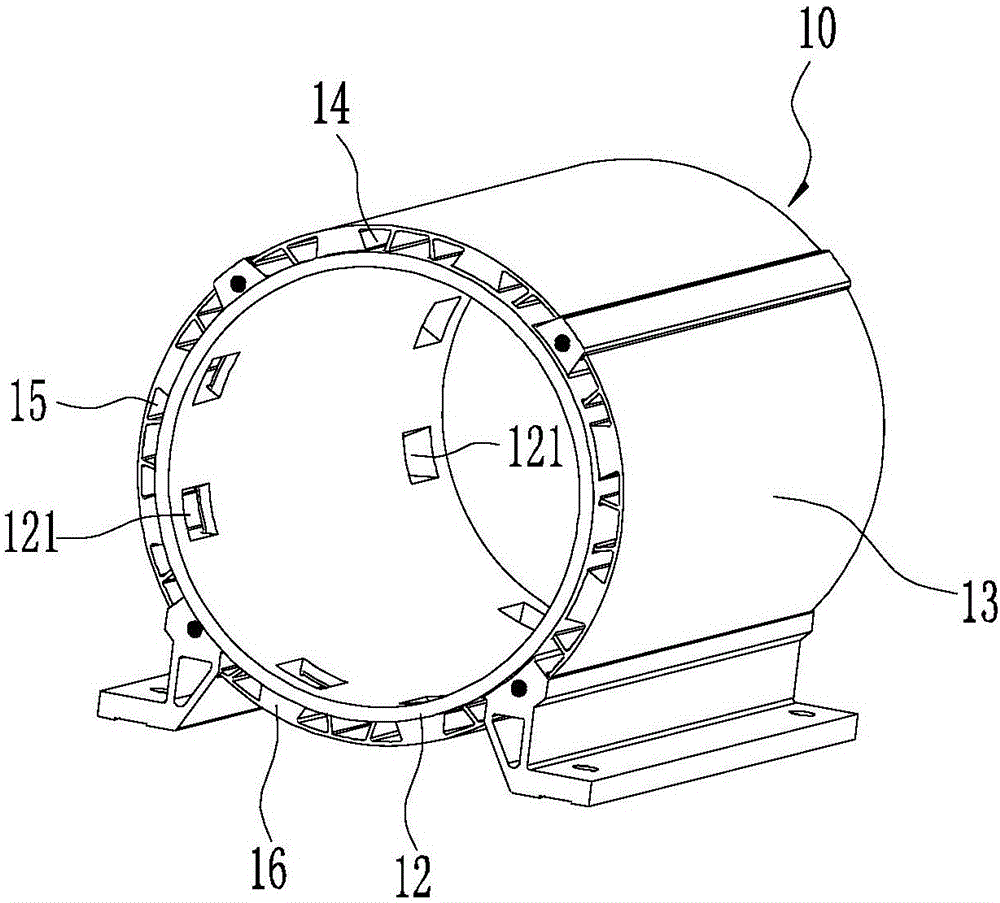

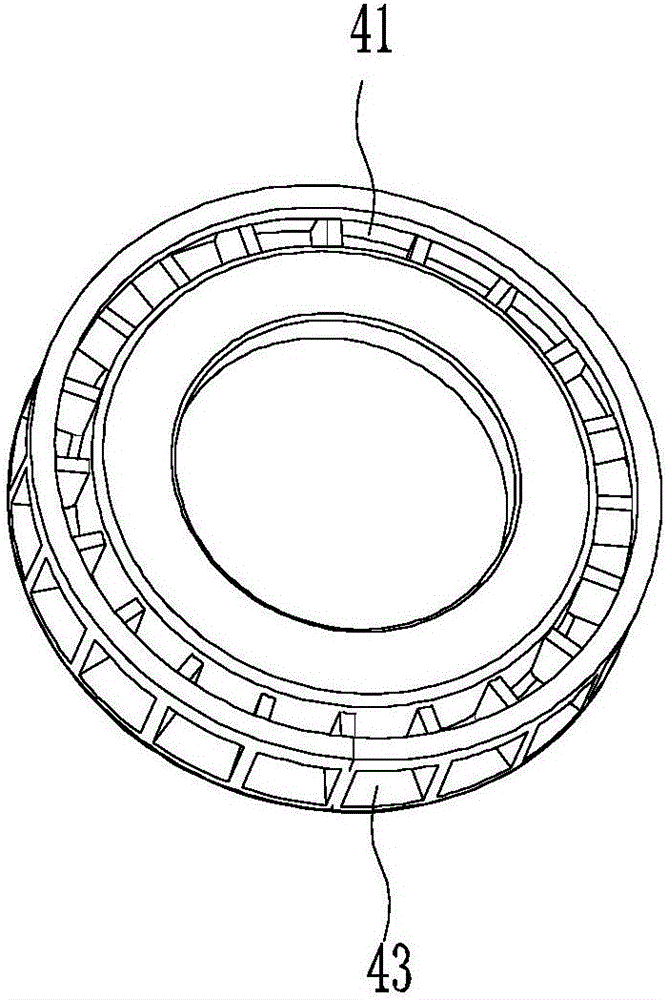

[0010] combine figure 1 , an electric motor, comprising a frame 10, a stator 20 and a rotor 30, characterized in that: a first air flow path 11 is arranged axially on the frame 10, and the two ends of the first air flow path 11 are respectively connected to the axial direction of the stator 20 On both ends, a vane windshield 40 is arranged at one end of the rotor 30, and the blade windshield 40 pushes the airflow to circulate along the airflow channel.

[0011] Since the first airflow path 11 is provided, combined with the airflow path formed by the air gap formed between the stator 20 and the rotor 30, the rotating shaft drives the blade windshield 40 to rotate synchronously when the motor is working, thereby pushing the airflow to circulate along the airflow path. The above scheme can timely and effectively exchange the heat in the motor chamber with the machine base, so that the motor can run in an ideal temperature environment.

[0012] As a preferred option, combined wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com