LED-COB optical engine driving device

A technology of LED-COB and driving device, applied in lighting device, light source, electric light source, etc., to achieve the effect of reducing heat dissipation temperature and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

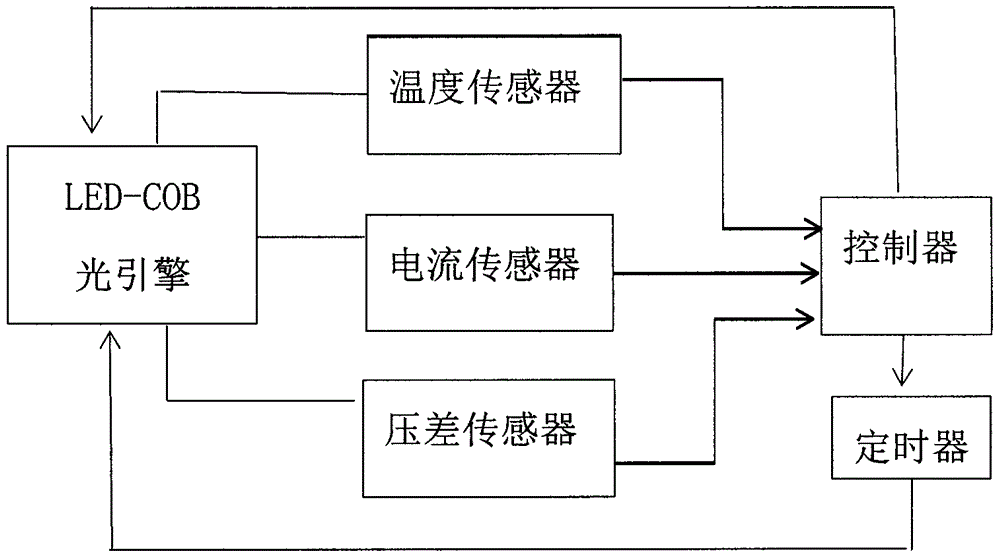

[0018] The present invention provides a technical solution: an LED-COB light engine driving device, including a temperature sensor 1, a current sensor 2, a differential pressure sensor 3, and a controller 4;

[0019] The temperature sensor 1 is set to detect the temperature of the LED-COB substrate;

[0020] The current sensor 2 is used to detect the current in the LED-COB circuit;

[0021] The differential pressure sensor 3 is used to detect the differential pressure across the LED-COB circuit;

[0022] The controller 4 is set to control the LED-COB according to the temperature detected by the temperature sensor 1

[0023] Wherein the controller 4 controls the voltage difference across the LED-COB circuit according to the comparison result of the temperature detected by the temperature sensor 1 and the stored intensity data to keep the light output of the LED-COB in different colors, and the intensity data is related to the temperature and The color of the LED-COB is associ...

Embodiment 2

[0026] The present invention provides a technical solution: an LED-COB light engine driving device, including a temperature sensor 1, a current sensor 2, a differential pressure sensor 3, and a controller 4;

[0027] The temperature sensor 1 is set to detect the temperature of the LED-COB substrate;

[0028] The current sensor 2 is used to detect the current in the LED-COB circuit;

[0029] The differential pressure sensor 3 is used to detect the differential pressure across the LED-COB circuit;

[0030] The controller 4 is set to control the driving current of the LED-COB light engine according to the temperature detected by the temperature sensor 1 .

[0031] Wherein the controller 4 controls the voltage difference across the LED-COB circuit to keep the light output of the LED in different colors according to the comparison result of the temperature detected by the temperature sensor 1 and the stored intensity data, and the intensity data is related to the temperature and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com