Oven for processing of dehydrated vegetables

A technology for dehydrated vegetables and an oven, which is applied in the field of ovens for processing dehydrated vegetables, can solve the problems of insufficient drying of vegetables, damage to vegetables, and insufficient temperature, so as to achieve perfect drying functions and conditions, low production cost, and good drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

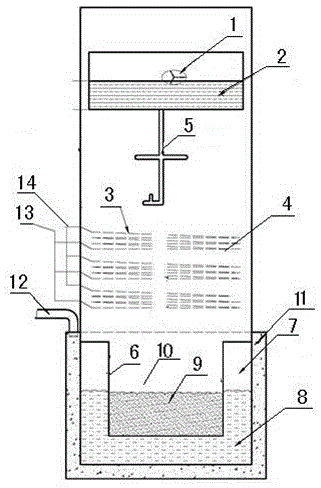

[0007] Depend on figure 1 It is known that an oven for processing dehydrated vegetables is composed of a drying tank, a hot and cold zone, and a drying zone. The drying tank is composed of an IPA tank 6, a heat transfer oil tank 7, a heat transfer oil 8, an IPA9, a steam zone 10, and a heat insulating layer 11. The exhaust air pipe 12 is composed of the hot and cold area composed of 3 ice water pipes, the ice water outlet pipe 13 and the ice water inlet pipe 14. The drying area is composed of the fan 1, the high-efficiency air filter element 2 and the lifting frame 5. The lifting frame The bottom of 5 is the IPA tank 6 of the drying tank. The upper part of the IPA tank 6 is the steam area 10, and the outside is the heat transfer oil tank 7. The heat transfer oil tank 7 is insulated with a heat insulating layer 11. The vegetables are placed in the lifting frame 5 and lowered to the IPA tank. 6 for cleaning, lifting frame 5 moves up, and vegetables enter steam zone 10 and conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com