Dust-free drying trough

A drying tank and clean air technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of cleaning effect, poor watermark under the film, dust point-like dirt, etc., and achieve perfect drying function and conditions, reduce the defective rate of products, and improve the effect of drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

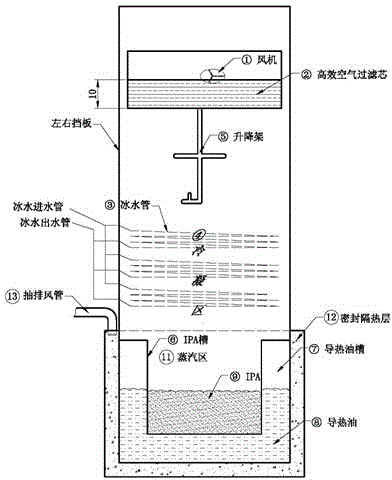

[0008] as attached figure 1 As shown, the present invention includes: the top of the fan 1 sends air downwards, and the airtight connection is made with a high-efficiency air filter element 2, and the filtered air is sent to the condensation area of the drying tank formed by three groups of ice water pipes 3; the bottom of the drying tank elevating frame is an IPA tank 6. The outside is a heat-conducting oil tank 7, and a time relay is added to the lifting frame circuit to control the time in the condensation zone when rising. The condensation zone 4 is composed of three sets of ice water pipes to prevent the IPA steam 9 from volatilizing too quickly, and make the water in the air near the condensation zone 4 The decrease of vapor content accelerates the volatilization of IPA9 on the surface of the lens and enhances the drying effect; during the drying process of the lens, it quickly drops from the condensation zone 4 to the vapor zone 11, and the IPA vapor 9 forms a clean IP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com