A kind of shell distribution type catalyst and its preparation method and a kind of Fischer-Tropsch synthesis method

A catalyst and shell technology, which is applied in the field of shell-distributed catalysts and its preparation, can solve the problems of cumbersome operation and difficulty in large-scale production, and achieve simple and easy-to-control operation process, high shell rate, and improved shell rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] 1. Put 200 kg of butterfly-shaped γ-alumina particles extruded from a 1.6 mm orifice plate (the particle length is 2-4 mm, and the water absorption rate is 0.8 ml / g) as a porous carrier and put it into the porous carrier storage tank 101 .

[0105] 2. Dissolving cobalt nitrate in water to prepare an impregnating liquid (calculated as CoO, the concentration of cobalt nitrate is 330 g / L) and placing it in the impregnating liquid storage tank 201 .

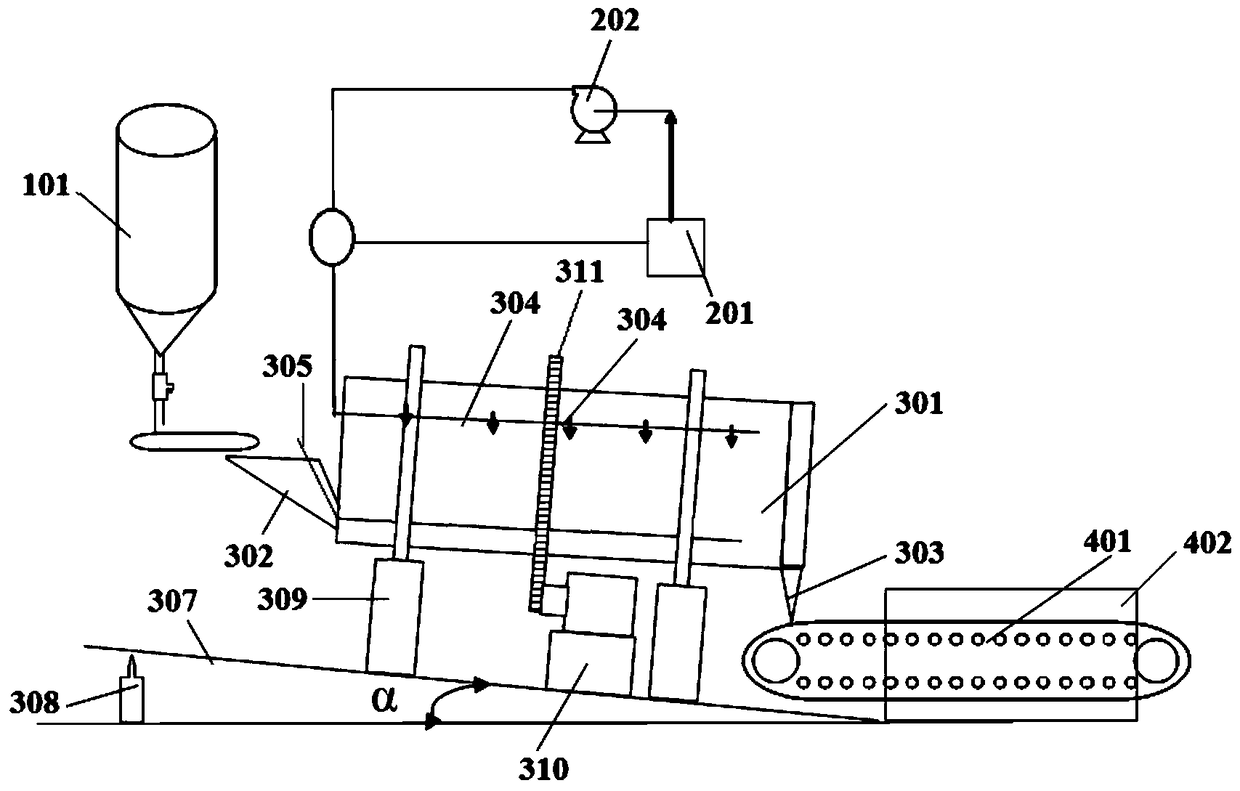

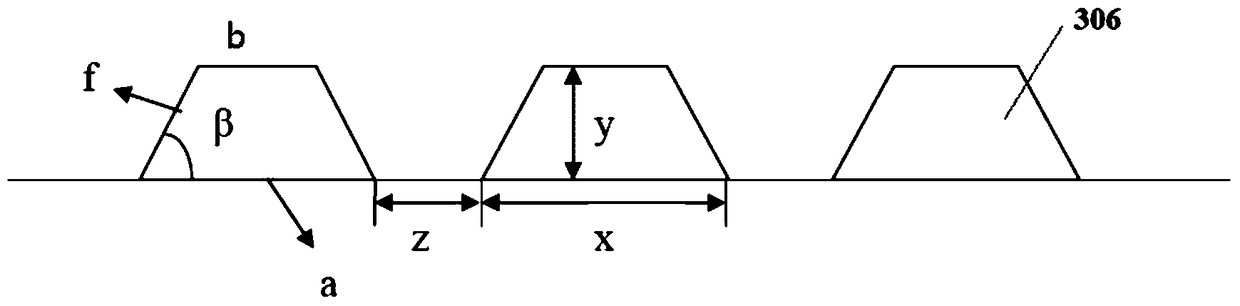

[0106] 3. Send the porous carrier into the hollow container 301, and rotate the hollow container 301 at the same time (the inner wall of the hollow container 301 is provided with a lifting plate 306, the radial section of the lifting plate 306 is trapezoidal, x=2.4y, β is 60° , z is 0.12R; the inclination angle of the axis of the hollow container 301 relative to the horizontal plane is 2°; the rotation speed is 5 revolutions / minute), and start the vacuum pump to vacuumize the hollow container 301 simultaneously (wherein, in the...

Embodiment 2

[0120] The catalyst was prepared by the same method as in Example 1, except that in step 3, during the spraying process, the vacuum conditions were not adjusted, and the partial pressure generated by water was up to 30kPa.

[0121] The composition and shell ratio of the prepared catalyst are listed in Table 1, and the relative percentage of cobalt element is listed in Table 2 from the outer layer to the core along the radial section of the porous carrier.

Embodiment 3

[0123] The catalyst was prepared by the same method as in Example 1, except that in Step 4, the drying temperature was 120°C.

[0124] The composition and shell ratio of the prepared catalyst are listed in Table 1, and the relative percentage of cobalt element is listed in Table 2 from the outer layer to the core along the radial section of the porous carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com