Automatic hole expanding equipment for taper holes in end parts of pipes

A technology for pipe fittings and taper holes, applied in the field of automatic reaming equipment, can solve the problems of not meeting the development requirements of modern manufacturing industry, high work intensity of workers, and difficulty in sustainable development, so as to reduce work intensity, improve production efficiency and product quality , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

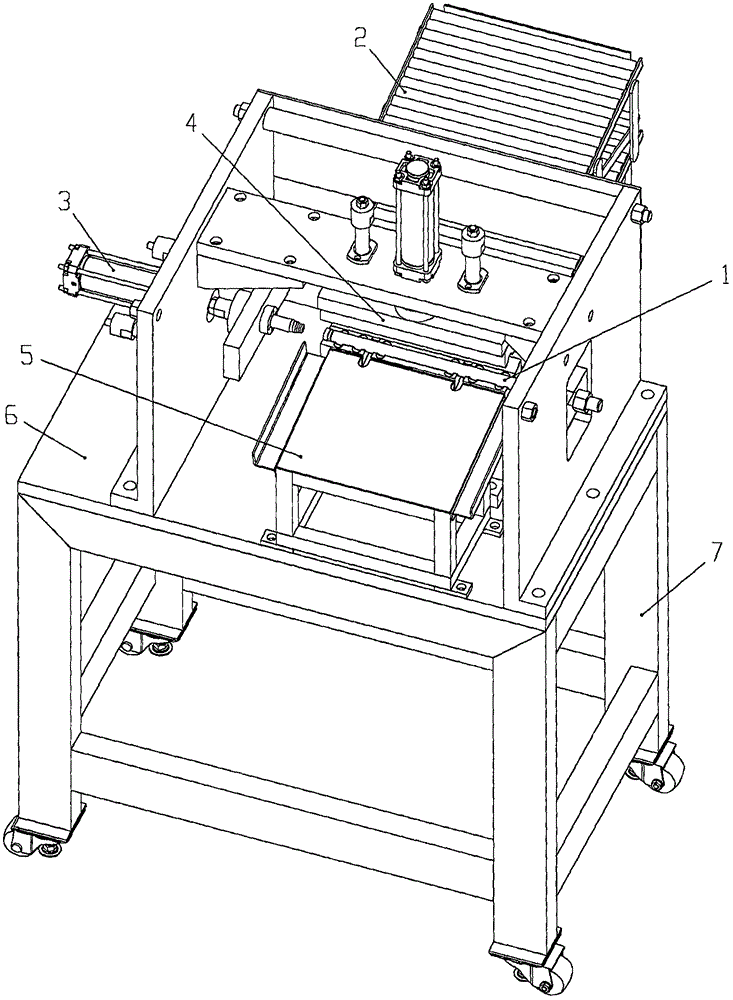

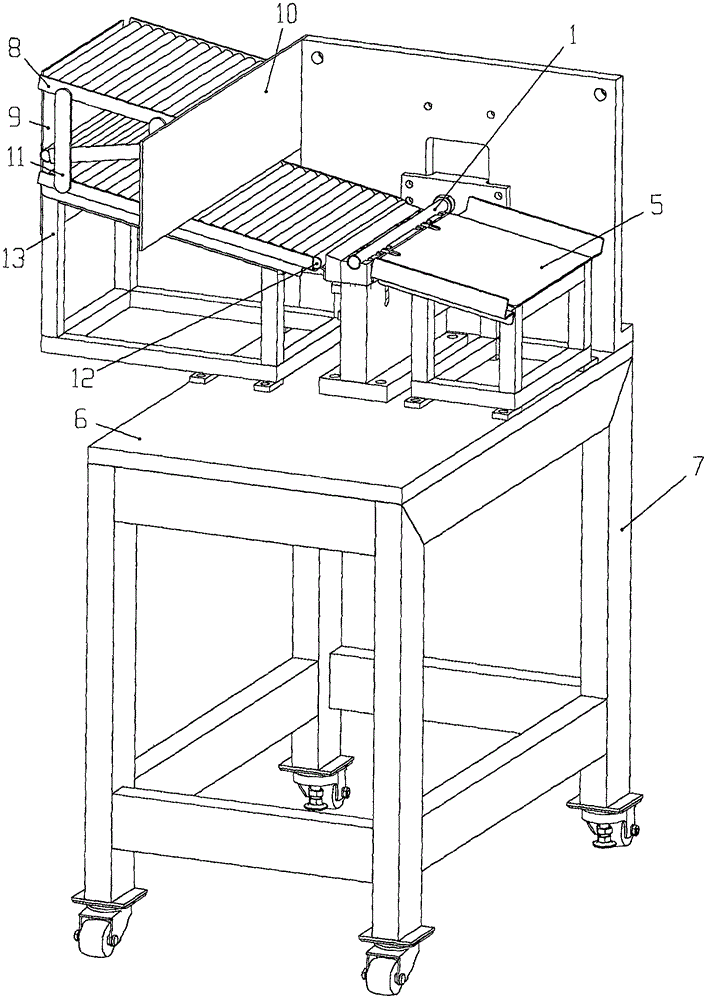

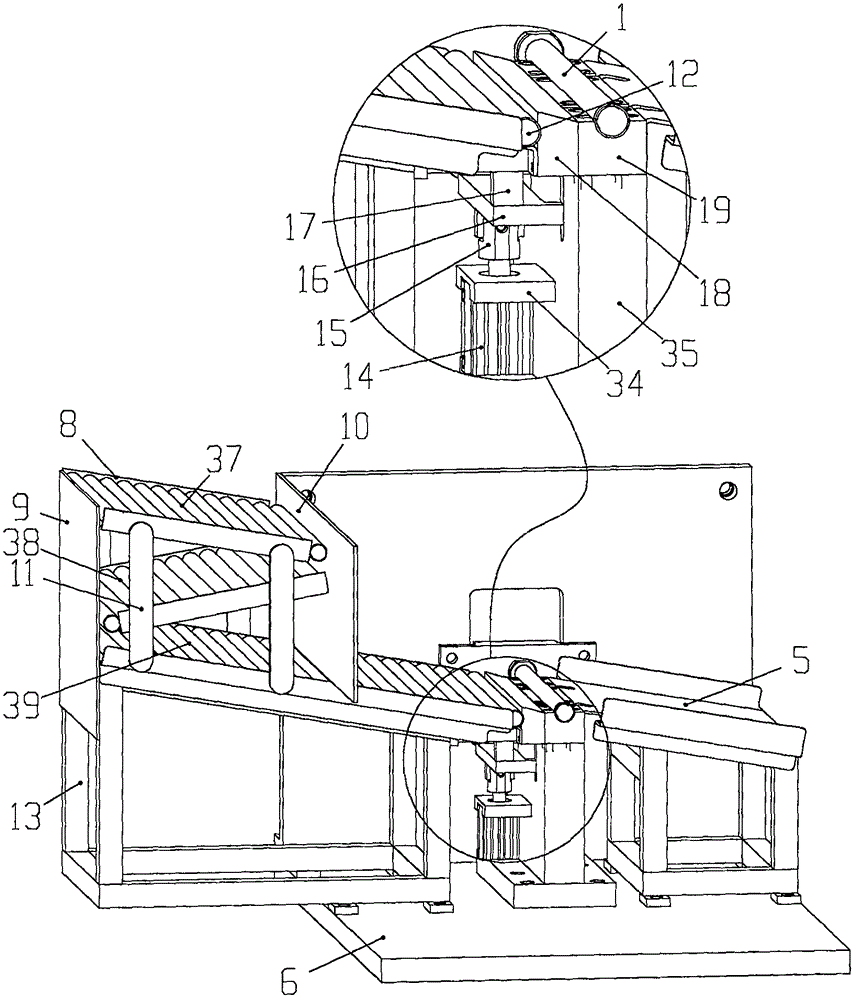

[0028]Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the purpose of the present invention is to provide an automatic reaming equipment for taper holes at the end of pipe fittings. A group of several pipe fittings is placed on the Z-shaped discharge frame 8, and then the pipe fittings 1 are automatically loaded through the feeding mechanism 2. , the pipe fitting is fixed by the tooling fixing mechanism 4, and the reaming mechanism 3 realizes automatic reaming and blanking, thereby realizing the automatic completion of the reaming process of the pipe fitting 1, greatly improving production efficiency and ensuring product quality.

[0029] figure 1 , 2 It is a structural schematic diagram of the taper hole automatic reaming equipment at the end of the pipe fitting of the present invention, image 3 , 4 It is a structural schematic diagram of the feeding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com