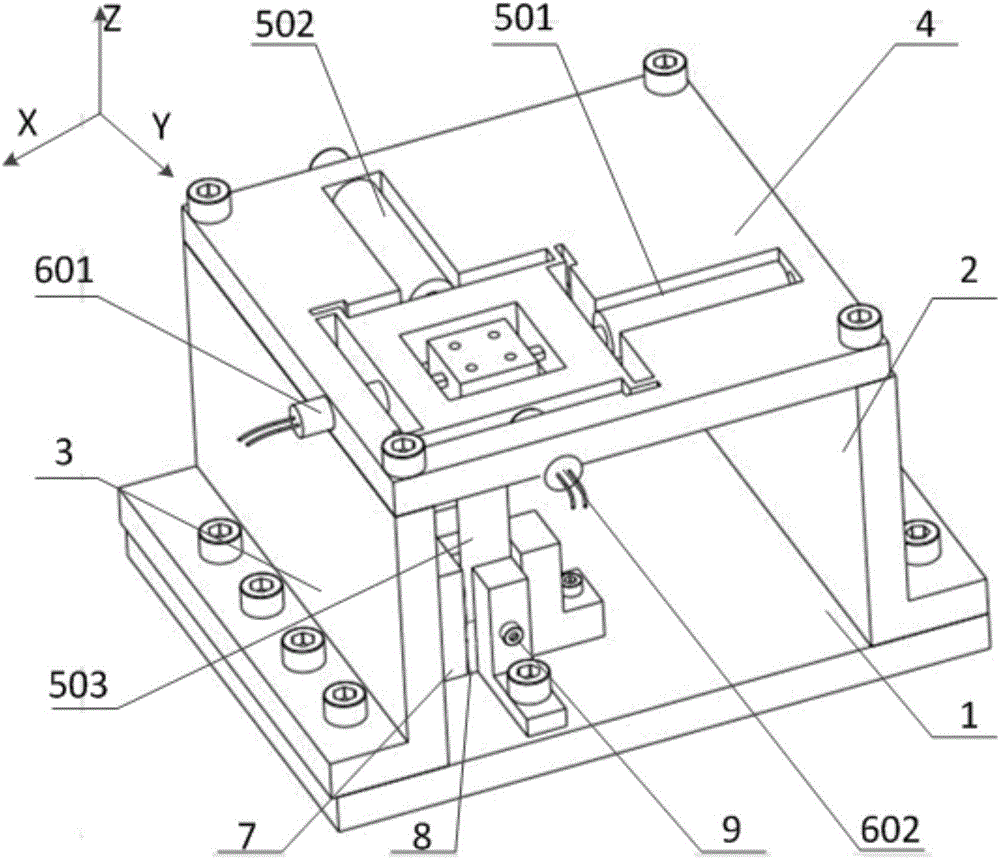

Three-dimensional oval micro displacement motion platform under three-piezoelectric perpendicular drive

A vertical drive and motion platform technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., to achieve the effect of simple fine-tuning process, small adjustable range and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

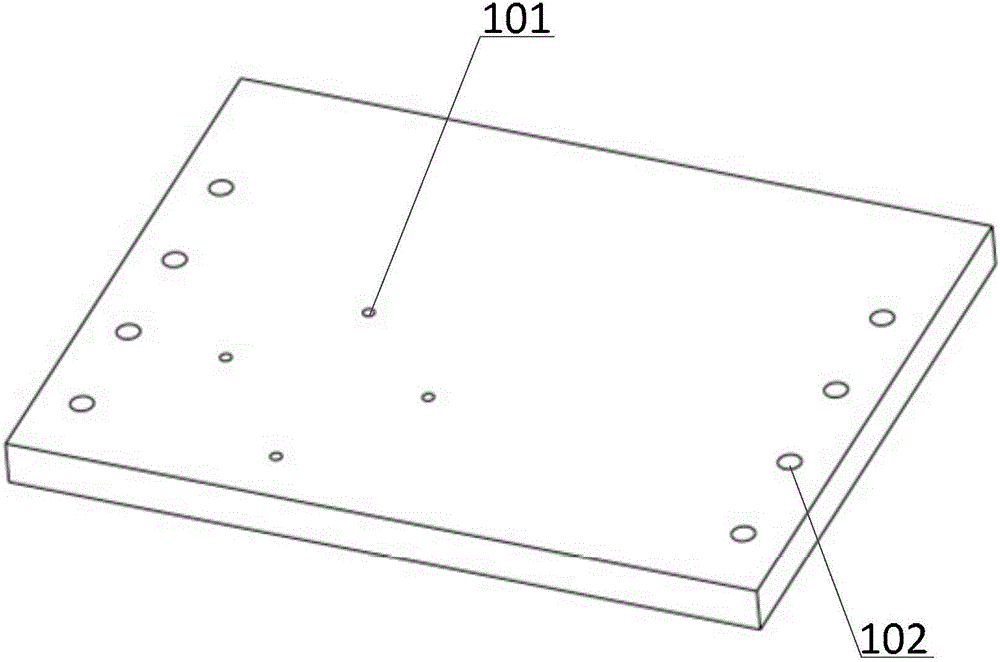

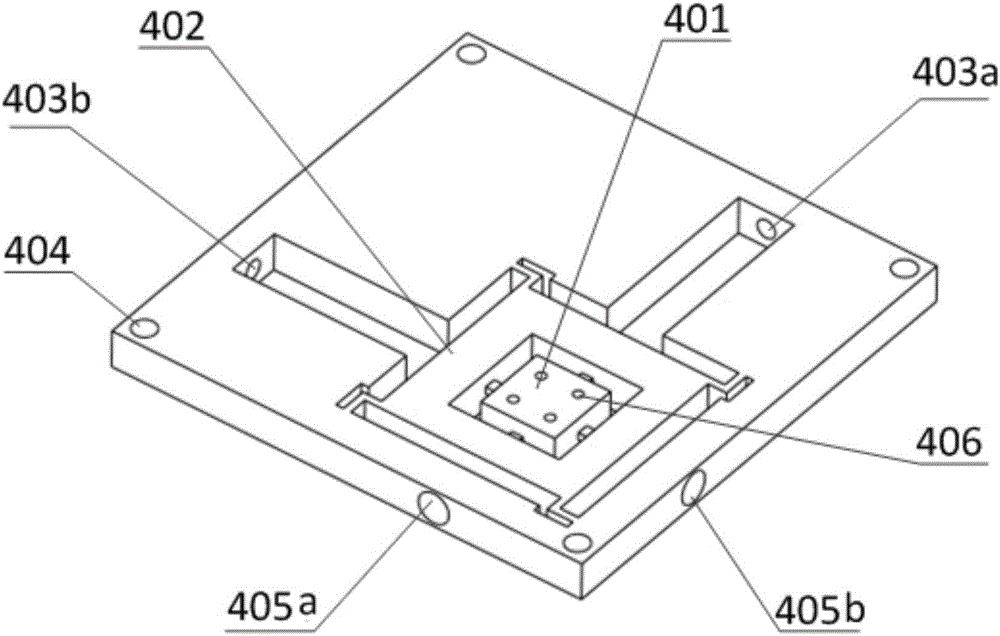

[0031] The right side plate 2 and the left side plate 3 are respectively fixedly connected with the base 1, and the upper plate 4 is fixedly connected with the right side plate 2 and the top of the left side plate 3 through the side plate connecting hole 404, and there are four center symmetrical plates on the upper plate 4. Distributed flexible hinges 402, four flexible hinges are connected around the workpiece base 401, the rear end of the X-axis piezoelectric stack 501 is connected to the X-axis piezoelectric stack fixing hole 403a on the upper plate, and the front end is in contact with the flexible hinges. The micro-displacement sensor 601 is connected to the X-axis micro-displacement sensor fixing hole 405a on the upper plate and is located on the opposite side of the X-axis piezoelectric stack, and the rear end of the Y-axis piezoelectric stack 502 is connected to the upper Y-axis piezoelectric stack fixing hole 403b plate , the front end is in contact with the flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com