Anti-slipping device of stacking manipulator gripper and working method of anti-slipping device

A technology of anti-slip devices and grippers, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of low intelligence, inability to automatically adapt to changes in object weight, etc., and achieve high reliability and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

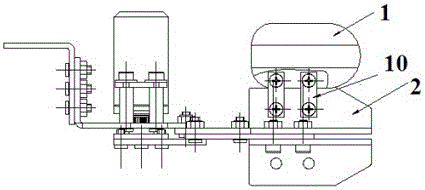

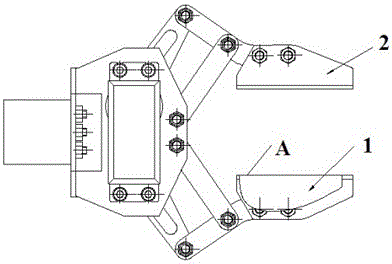

[0030] In the anti-slip device of the palletizing manipulator gripper of the present invention, the anti-slip device 1 is installed on the gripper 2 , and a contact photoelectric slip sensor 3 is installed in the anti-slip device 1 .

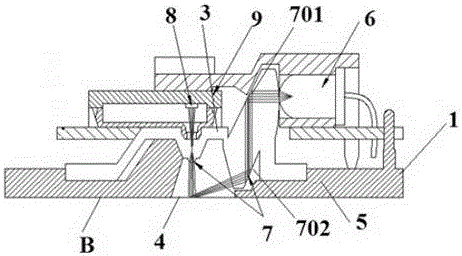

[0031] Further, in order to design reasonably, the above-mentioned contact photoelectric slip sensor is used to sense the contact information and slip speed information of the gripper relative to the object, and automatically adjust the required gripping force.

[0032] Further, for rational design, the contact plane of the anti-slip device is coplanar with the plane of the holder.

[0033] Further, the above-mentioned anti-slip device 1 is in contact with the object to be clamped during the clamping process.

[0034] Further, in order to design rationally, the above-mentioned anti-slip device 1 includes a main body 5 with a light receiving and sending window 4, and a light emitting diode 6, a lens 7 and a light receiving sensor 8 arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com