Intelligent robot assisting rapid modeling and 3D printing device

An intelligent robot and 3D printing technology, applied in the field of 3D printing, can solve the problems of low processing precision, complexity, and poor processing surface quality, and achieve the effect of simplifying the 3D printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

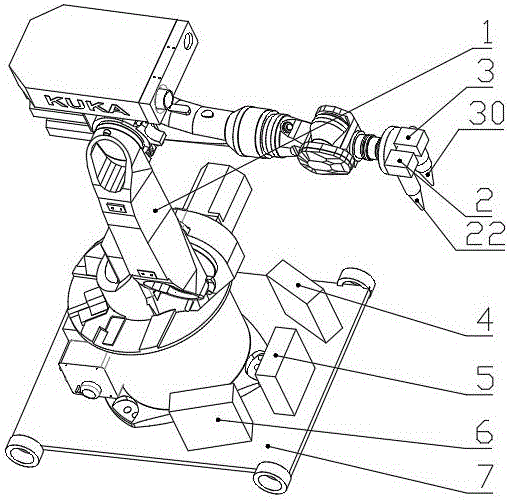

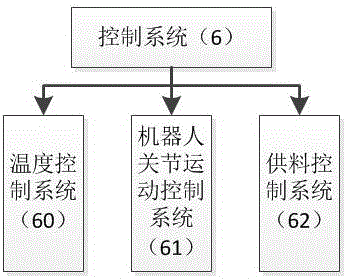

[0029] An intelligent robot-assisted rapid modeling and 3D printing device in this example is characterized in that it includes a robot (1), a 3D printing system (2), a measurement system (3), a data processing system (4), an image processing system ( 5), control system (6), mobile platform (7); the robot (1) is fixedly installed on the mobile platform (7); the 3D printing system (2) is fixedly installed on the tool end of the robot (1), It moves synchronously with the tool end of the robot (1); the measurement system (3) is fixedly installed on the tool end of the robot (1), and its relative position with the 3D printing system (2) is fixed, and it moves with the tool end of the robot (1). side-to-side synchronous movement; the measurement system (3) is used for rapid establishment of 3D printing models; the data processing system (4) is fixedly installed on the mobile platform (7); the image processing system (5) is fixedly installed on the mobile platform on the platform (7...

Embodiment 2

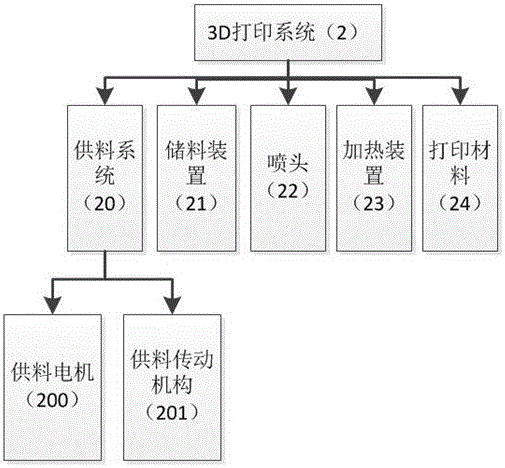

[0035] The 3D printing system (2) described in this example further includes: a feeding system (20), a storage device (21), a nozzle (22), a heating device (23), and printing materials (24); the feeding system ( 20) It further includes a feeding motor (200) and a feeding transmission mechanism (201); the feeding motor (200) drives the feeding transmission mechanism (201) to move the printing material (24) into the heating device (23) The printing material (24) is heated and melted and then extruded through the nozzle (22) for printing, and the rest is the same as in the first embodiment.

Embodiment 3

[0037] The measurement system (3) described in this example further includes a measuring probe (30), which can be retracted; when the measurement is started, the measuring probe is extended to perform the measurement; after the measurement is completed, the measuring probe (30) is retracted without hindering 3D printing works, and all the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com