Control system of 3D printing device

A control system, 3D printing technology, applied in general control system, control/regulation system, program control and other directions, can solve the problems affecting printing quality, speed and accuracy, and achieve the effect of low cost, high precision and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

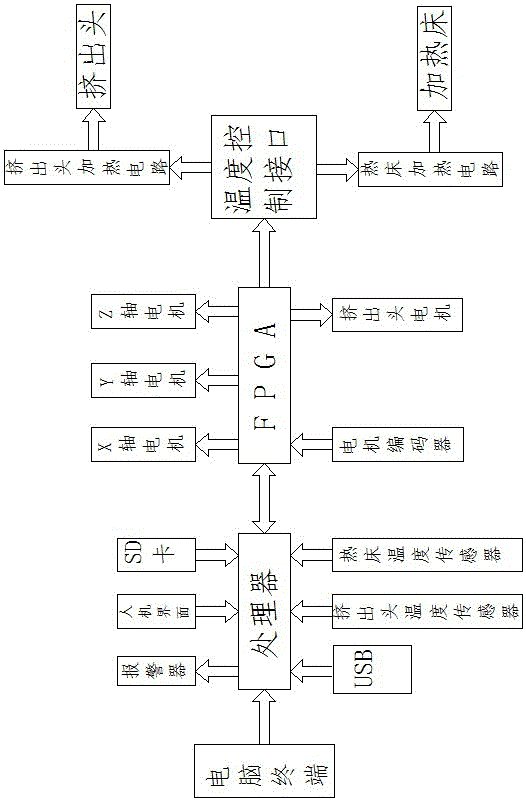

[0014] like figure 1 As shown, a control system of a 3D printing device includes a computer terminal, the computer terminal is connected to a processor through a data line, and the input end of the processor is respectively connected to a USB interface and a man-machine interface through a signal line , SD card interface, extrusion head temperature sensor and hot bed temperature sensor, the output end of processor is respectively connected with alarm and FPGA by signal line, and the output end of described FPGA is respectively connected with X-axis motor, Y-axis motor, The Z-axis motor and the temperature control interface, the temperature control interface is respectively connected to the extrusion head heating circuit and the hot bed heating circuit, the extrusion head heating circuit is connected to the extrusion head, and the hot bed heating circuit is connected to There is a heated bed, and the input of the FPGA is connected to a motor encoder.

[0015] The present inven...

Embodiment 2

[0017] like figure 1 As shown, a control system of a 3D printing device includes a computer terminal, the computer terminal is connected to a processor through a data line, and the input end of the processor is respectively connected to a USB interface and a man-machine interface through a signal line , SD card interface, extrusion head temperature sensor and hot bed temperature sensor, the output end of processor is respectively connected with alarm and FPGA by signal line, and the output end of described FPGA is respectively connected with X-axis motor, Y-axis motor, The Z-axis motor and the temperature control interface, the temperature control interface is respectively connected to the extrusion head heating circuit and the hot bed heating circuit, the extrusion head heating circuit is connected to the extrusion head, and the hot bed heating circuit is connected to There is a heating bed, and the input end of FPGA is connected with a motor encoder, and the processor is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com