High-wear-resistant resin floorboard

A high wear-resistant, resin technology, applied in the field of building materials, can solve the problems of affecting appearance, poor wear resistance, poor drainage, etc., and achieve excellent drainage function and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

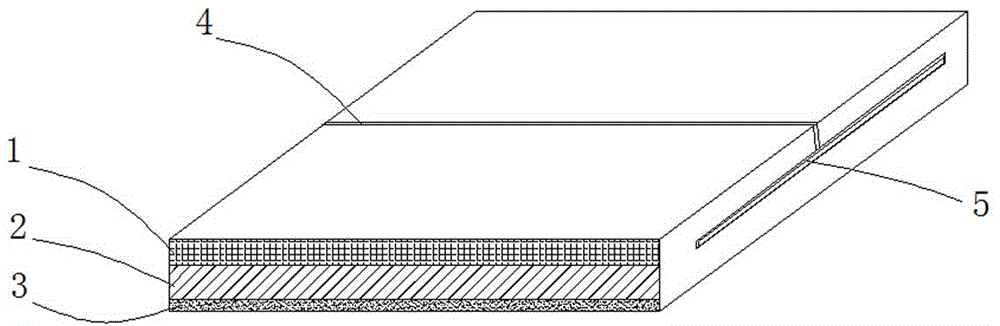

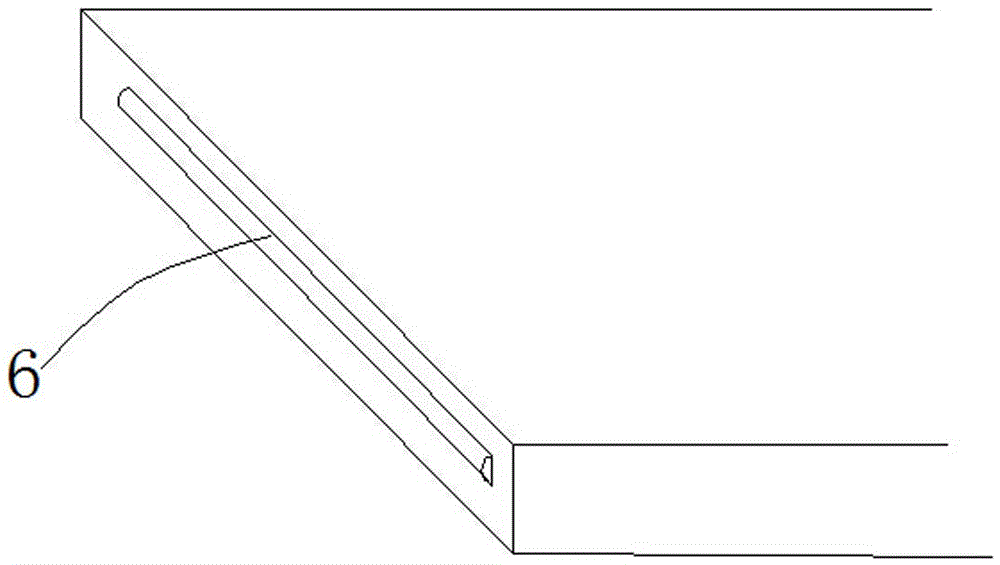

[0029] Specific embodiment 1: a high wear-resistant resin floor, including a surface layer 1 with high wear resistance, a body layer 2, and a bottom layer 3 with a high heat insulation effect, the body layer 2 is located between the surface layer 1 and the bottom layer 3, and the The surface layer 1, the main body layer 2 and the bottom layer 3 are bonded to each other by an adhesive. One side of the resin floor is processed with a fixing groove 5. The side can be any side, and the opposite side of the side with the fixing groove 5 is processed. Positioning post 6 is processed, the fixing groove 5 cooperates with the positioning post 6 of the adjacent floor, the fixing groove 5 is processed with micro-guiding groove 4 along the height direction and horizontal direction, and the cross-section of micro-guiding groove 4 is arc-shaped , the inner wall of the fixing groove is provided with a layer of water-absorbing layer, the water-absorbing layer and the fixing groove are connecte...

specific Embodiment 2

[0050] Step 3: Add the particles after step 2 into the floor mold, add a curing agent, and cure and shape. Specific embodiment 2: a high wear-resistant resin floor, including a surface layer 1 with high wear resistance, a body layer 2, and a bottom layer 3 with a high heat insulation effect, the body layer 2 is located between the surface layer 1 and the bottom layer 3, and the The surface layer 1, the main body layer 2 and the bottom layer 3 are bonded to each other by an adhesive. One side of the resin floor is processed with a fixing groove 5. The side can be any side, and the opposite side of the side with the fixing groove 5 is processed. Positioning post 6 is processed, the fixing groove 5 cooperates with the positioning post 6 of the adjacent floor, the fixing groove 5 is processed with micro-guiding groove 4 along the height direction and horizontal direction, and the cross-section of micro-guiding groove 4 is arc-shaped , the inner wall of the fixing groove is provide...

specific Embodiment 3

[0055] Step 3: Add the particles after step 2 into the floor mold, add a curing agent, and cure and shape. Specific embodiment 3: a high wear-resistant resin floor, including a surface layer 1 with high wear resistance, a body layer 2, and a bottom layer 3 with a high heat insulation effect, the body layer 2 is located between the surface layer 1 and the bottom layer 3, and the The surface layer 1, the main body layer 2 and the bottom layer 3 are bonded to each other by an adhesive. One side of the resin floor is processed with a fixing groove 5. The side can be any side, and the opposite side of the side with the fixing groove 5 is processed. Positioning post 6 is processed, the fixing groove 5 cooperates with the positioning post 6 of the adjacent floor, the fixing groove 5 is processed with micro-guiding groove 4 along the height direction and horizontal direction, and the cross-section of micro-guiding groove 4 is arc-shaped , the inner wall of the fixing groove is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com