Automobile relay valve

A technology for relay valves and automobiles, which is applied in the direction of brakes, brake components, vehicle components, etc. It can solve the problems of unstable air flow at the air intake, insufficient braking force, and filter blockage, etc., to ensure smoothness and stability, The effect of reducing the risk of clogging and increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

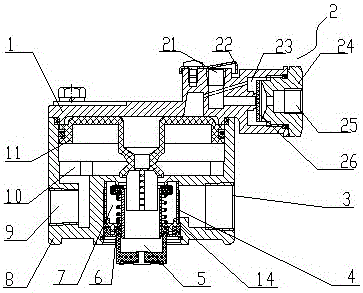

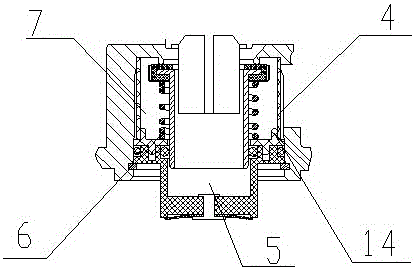

[0022] Such as figure 1 As shown, the automobile relay valve includes an upper valve body 1, a lower valve body 8 and a relay piston 11, the lower valve body 8 is provided with an air inlet 3 and an air outlet 9, and the air inlet 3 and the A piston assembly is provided between the air outlets 9; the upper valve body 1 is provided with a control port 2, and a filter screen 4 is provided in the valve body chamber 7, and the filter screen 4 is cylindrical and a piston The assembly is wrapped in the filter screen 4; a limit step 14 is provided between the filter screen 4 and the piston assembly; the lower valve body 8 is provided with a valve body chamber 7 and a relay piston chamber 10, and the described The valve body chamber 7 communicates with the relay piston chamber 10; the air inlet 3 communicates with the valve body chamber 7, and the gas outlet 9 communicates with the relay piston chamber 10; the gas enters from the air inlet 3 and passes through the valve The body cham...

Embodiment 2

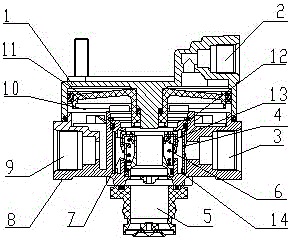

[0025] Such as figure 2 The difference between the shown automobile relay valve and the first embodiment is that the piston assembly includes a spring 6, a spring seat and a cup 13, and the cup 13 is ring-shaped; one end of the spring 6 is connected to the On the spring seat, the other end is connected with the leather cup 13. The lower valve body 8 also includes a valve seat 12. In a natural state, the leather cup 13 is in sealing contact with the valve seat 12 under the action of the spring 6. The control port 2 A two-way valve is provided to replace the diaphragm of the first embodiment. A sealing ring is provided between the valve seat 12 and the lower valve body 8, and a one-way valve is used to replace the diaphragm structure, so the performance is more reliable.

[0026] The automobile relay valve mentioned above reduces the water vapor and impurities entering the valve body, greatly reduces the failure rate of the gas circuit, and prolongs the service life of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com