Rubber belt conveyor capable of realizing multi-point unloading and use method thereof

A belt conveyor, multi-point technology, used in mine production and metallurgy fields, can solve the problems of harsh operating environment and low labor efficiency, and achieve the effect of improving the working environment, reducing the number of operators, and improving the level of automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

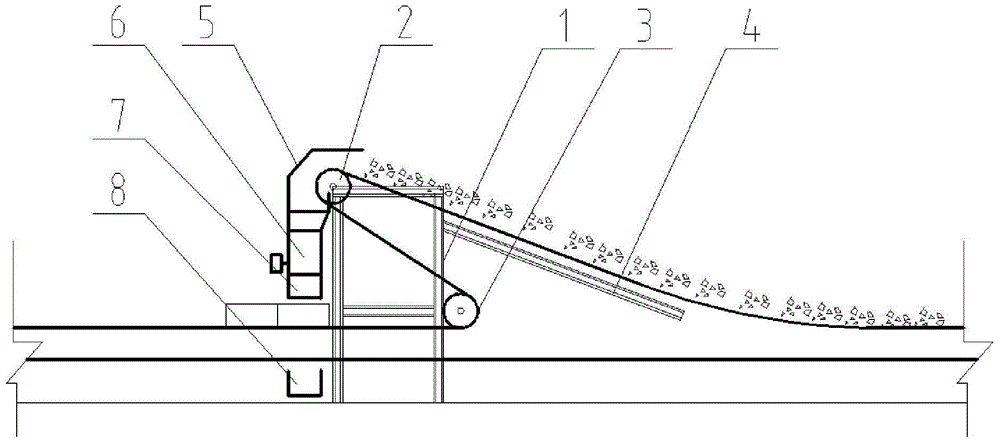

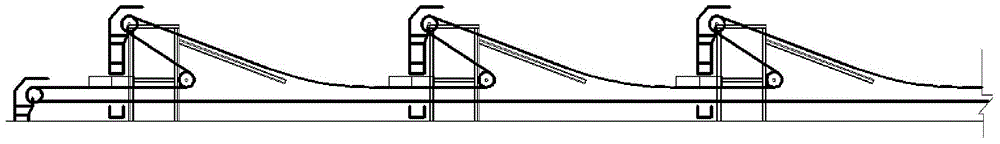

[0026] like Figure 1-Figure 2 Shown, the tape conveyor of multi-point unloading of the present invention mainly comprises support 1, front end reversing drum 2, rear end reversing drum 3, inclined beam 4, funnel 5, electric three-way 6 (or electric four-way), The positive discharge chute 7, the side discharge chute 8, etc., the specific structure is as follows:

[0027] A new type of unloading device is provided at any unloading point (except the head unloading point), and the new unloading device is divided into two parts: the support 1 and the unloading chute. There are two reversing rollers on the bracket 1: the front reversing roller 2 and the rear reversing roller 3, the front reversing roller 2 is located at the upper front end of the bracket 1, and the rear reversing roller 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com