Bottle opener

A bottle opener and bottle cap technology, applied in the field of bottle openers, can solve the problems of user's hand muscle damage, difficulty in opening the bottle cap, and contamination of reagents in the bottle, so as to avoid pollution, make the opening process simple and coherent, and reduce dead ends Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

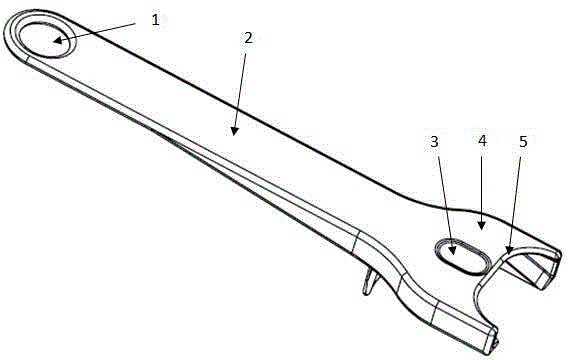

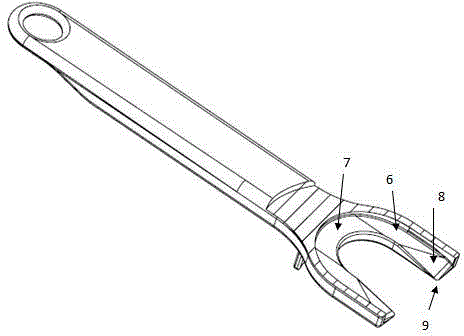

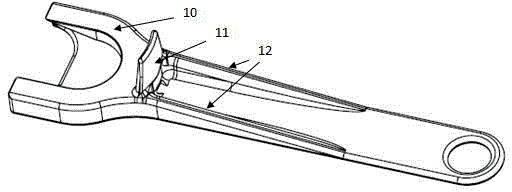

[0024] figure 1 and image 3 The overall shape of an embodiment of the bottle opener of the present invention is shown, figure 2 shows part of the internal structure of the embodiment, Figure 4 shows curved spaces.

[0025] The bottle opener of the present invention is mainly composed of a handle 2, a U-shaped groove, a top cover 4, a bending space 13 and a partition 11.

[0026] There is a hole 1 at the end of the handle 2, which is convenient for hanging the bottle opener, and can also reduce the amount of material used and increase the appearance.

[0027] The inner upper surface of the two arms of the U-shaped groove is a slope 8, which rises from the front opening of the U-shaped groove to the rear, and rises from the inside to the outside; Two blades 9 form an outer figure-eight, and this blade 9 can cut into the gap between the bottle cap skirt and the bottleneck from the bottle cap 14 both sides simultaneously.

[0028] The inner width of the U-shaped groove is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com