Wastewater treatment facility

A waste water treatment and equipment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Unreasonable design and other problems, to achieve the effect of reasonable structure, simplified structure and improved driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

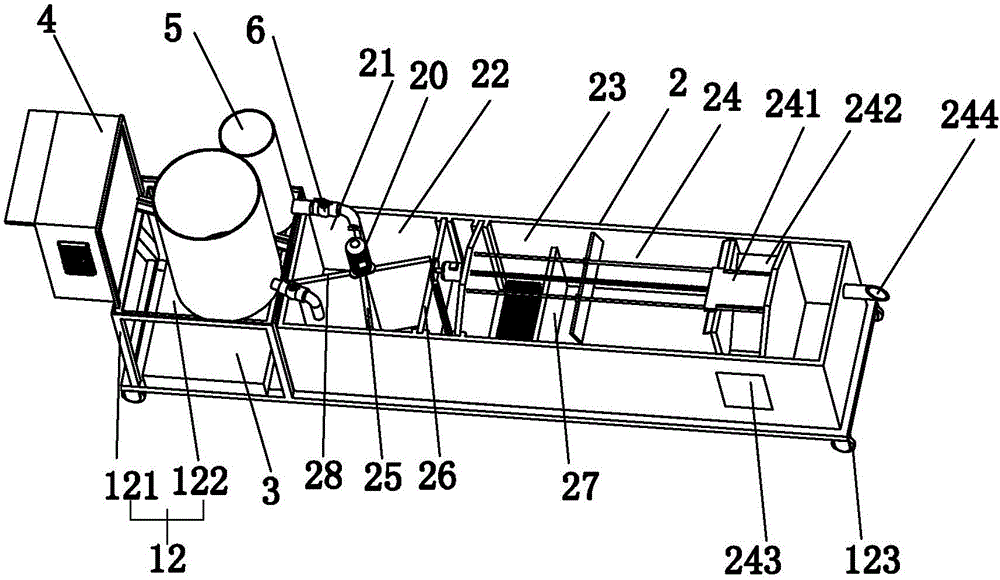

[0031] A waste water treatment equipment includes a support 1 , a treatment pool 2 and a distribution box 3 .

[0032] The bracket 1 is a cart-type structure, which includes a bottom mounting base 11 and a push base 12. The side of the bottom mounting base 11 facing the ground is provided with a runner 12313 for conveniently pushing on the ground; the push base 12 includes installation from bottom to top. frame 121 and mounting plate 122 . The mounting plate 122 is provided with a medicine storage box 5, and the opening of the medicine storage box 5 is provided with a shut-off valve 6, and the shut-off valve 6 is signal-connected to the control device 4 for controlling its automatic opening and closing. Both the distribution box 3 and the control device 4 are fixedly installed on the installation frame 121 .

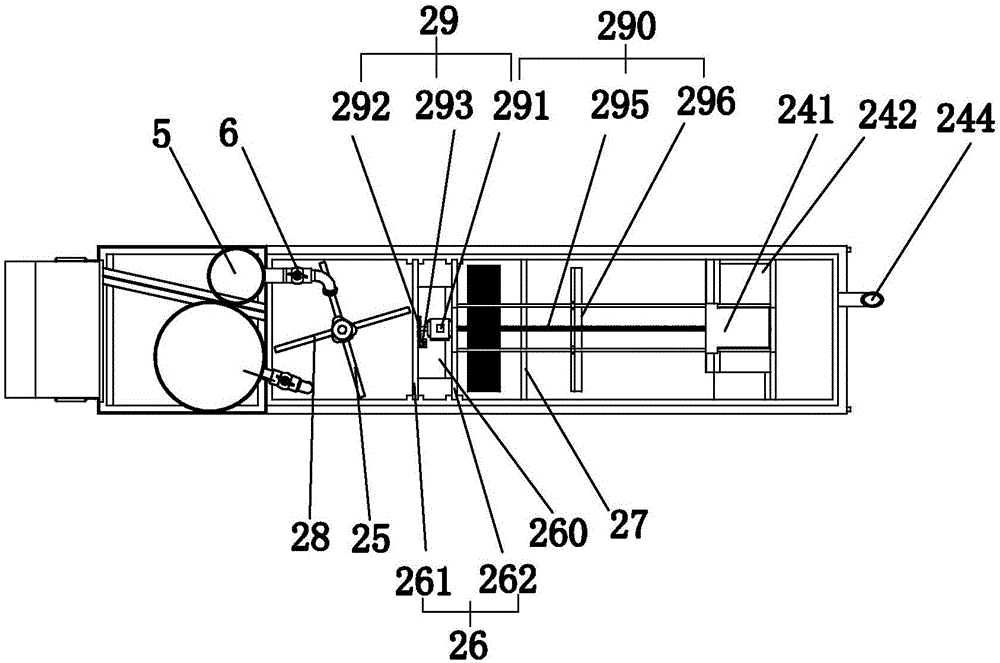

[0033] The treatment pool 2 comprises a dosing pool 21, a reaction chamber 22, an electrical floating chamber 23 and a discharge chamber 24 in turn, and a first isolati...

Embodiment 2

[0040] Different from Embodiment 1, the power source of the second drive mechanism 29 is separated from the power source of the oil skimmer 290, the power source of the oil skimmer 290 is the second drive motor, and the second drive mechanism 29 is the third drive motor, In addition, the first driving motor, the second driving motor, and the third driving motor are all single-axis motors.

Embodiment 3

[0042] Different from Embodiment 1, the power source of the second drive mechanism 29 is separated from the power source of the oil skimmer 290, the power source of the oil skimmer 290 is the second drive motor, and the second drive mechanism 29 is a telescopic cylinder or hydraulic cylinder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com