Pretreatment device for printing and dyeing production line and printing and dyeing production

A production line and pretreatment technology, used in desizing, pretreatment equipment for printing and dyeing production, scouring and bleaching production lines, can solve the problems of long equipment assembly line, long operation time, environmental pollution, etc., to achieve simplified material feeding, simple and easy implementation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0086] In this description, the examples involved all adopt cotton cloth as the printing and dyeing cloth.

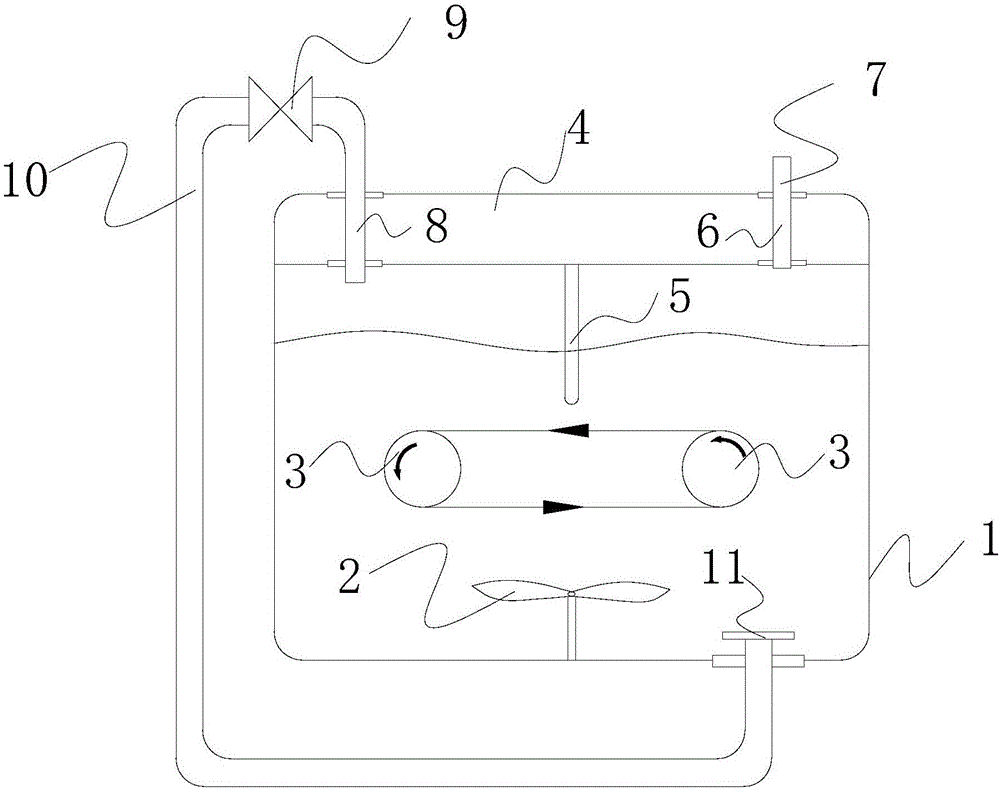

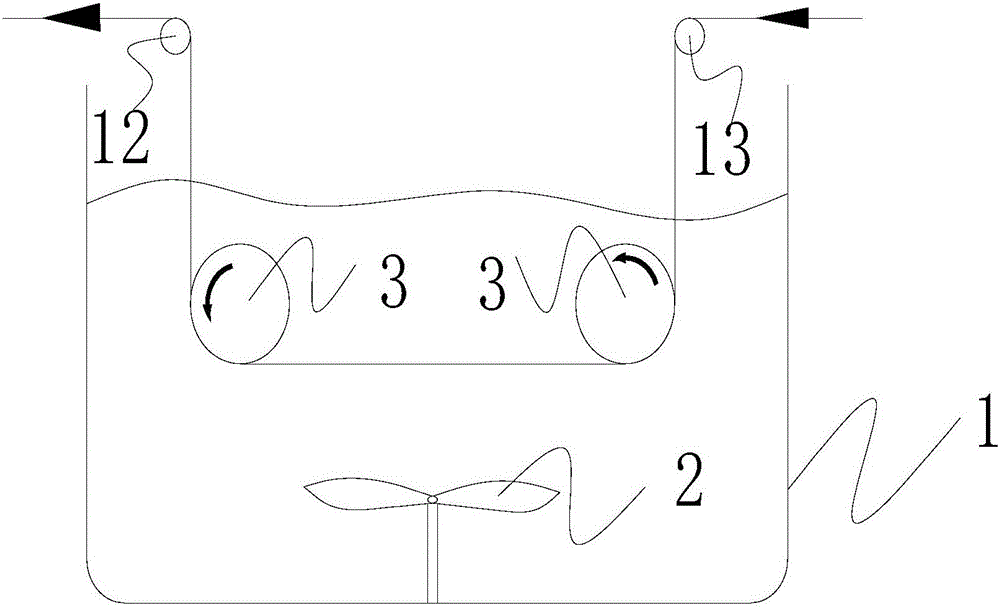

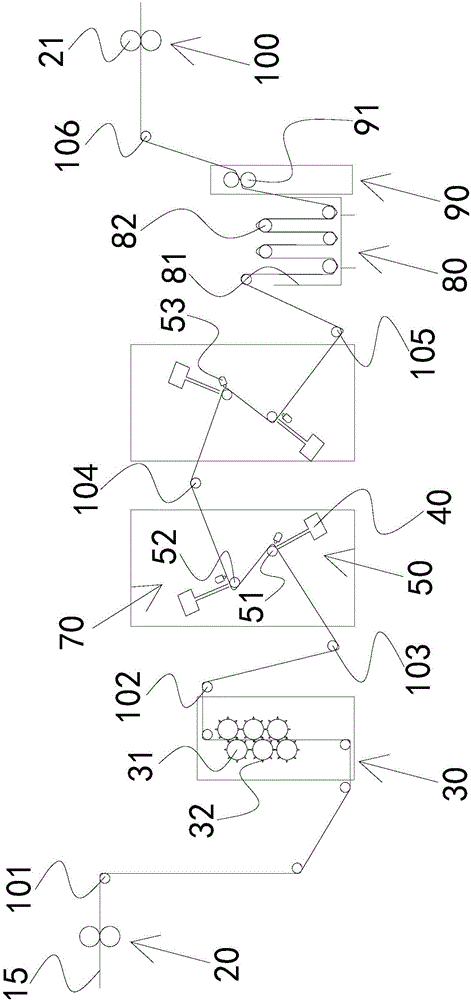

[0087] The printing and dyeing production line includes singeing equipment, pre-processing equipment, mercerizing machine, dyeing and printing equipment, and finishing equipment in sequence along the fabric treatment process; the pre-processing equipment is used for desizing, refining and bleaching, and the pre-processing equipment includes pools, Stretch rollers and power units.

[0088] see figure 1 Example shown. In this embodiment, the cell body 1 is rectangular, and the cell body 1 is made of insulating materials, such as enamel, glass, plastic and other non-conductive materials, and the cell body 1 is filled with a NaCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com