Beam column connection piece

A technology of beam-column connection and connection part, which is applied in the field of connection parts, can solve the problems of inability to realize large-scale standardized production, reduce installation efficiency, and increase installation difficulty, so as to improve installation efficiency, anti-seismic function, utilization rate and aesthetics , reducing the effect of the connection link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

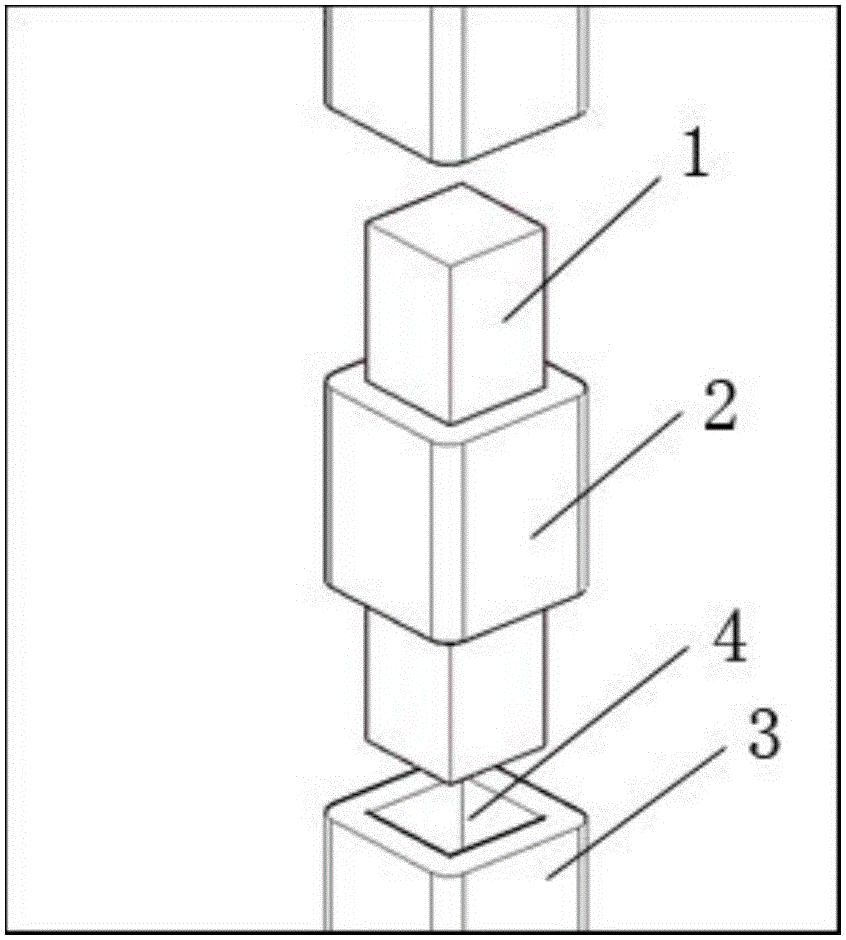

[0024] Such as figure 1 As shown, the present invention includes a connection body 2, the upper and lower ends of the connection body 2 extend a square column connection part 1, the center of the column connection part 1 coincides with the center of the end face of the connection body 2, and the end of the column 3 is concave A column connection part installation groove 4 is formed to cooperate with the column connection part 1. The upper and lower ends of the column connection part 1 are respectively connected to the column 3 through the column connection part installation groove 4. The cross-section shape of the connecting body 2 is the same as that of the column 3.

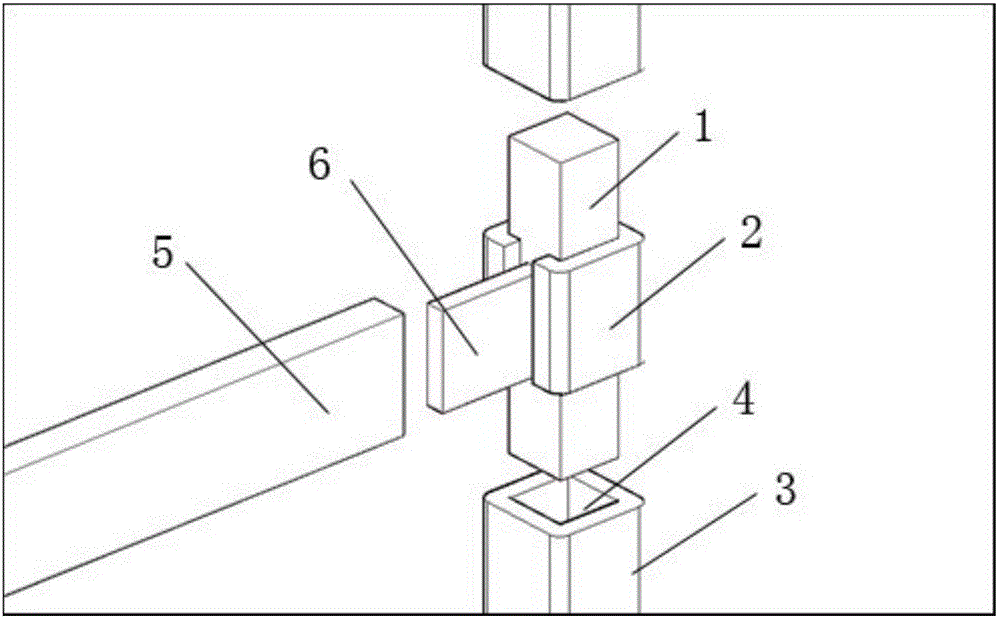

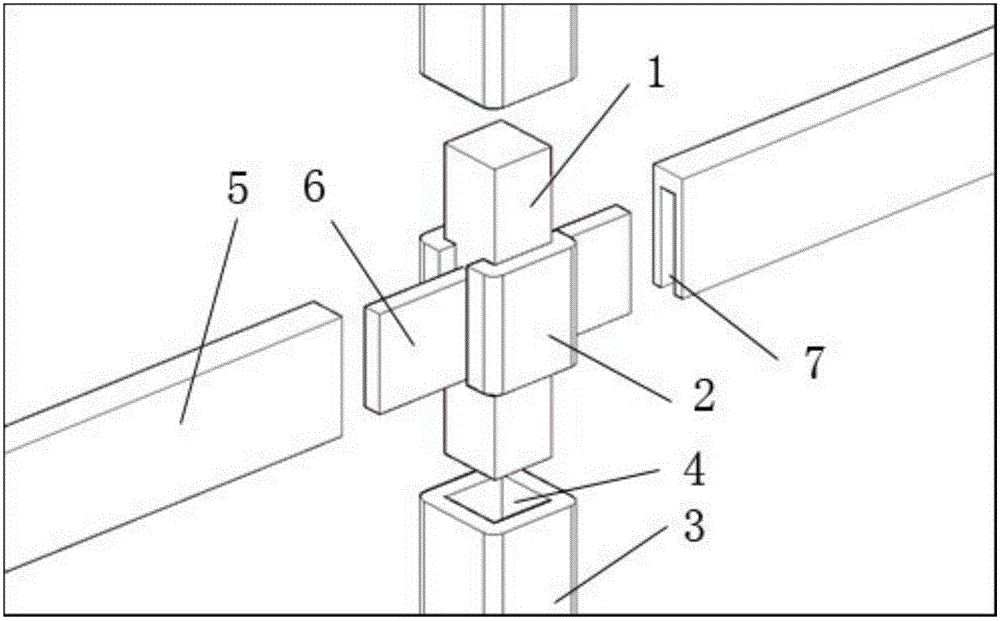

[0025] Furthermore, in the middle of the side of the connecting body 2 is provided with at least one beam connecting portion 6 that hangs outwards in a square shape. The verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com