Longitudinal welded pipe welding seam protrusion detecting system based on laser scanning

A technology of straight seam welded pipe and detection system, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the weld seam pout detection of straight seam welded pipes cannot be realized, and achieve the improvement of product qualification rate, production efficiency and adaptability Strong, high-precision judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

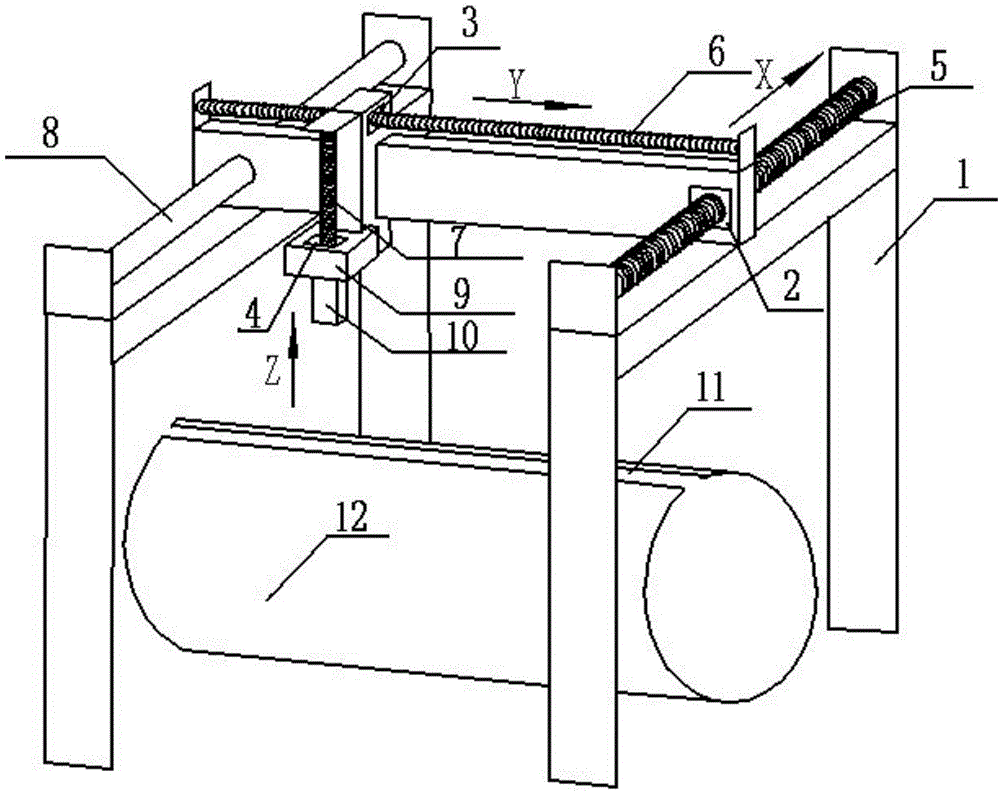

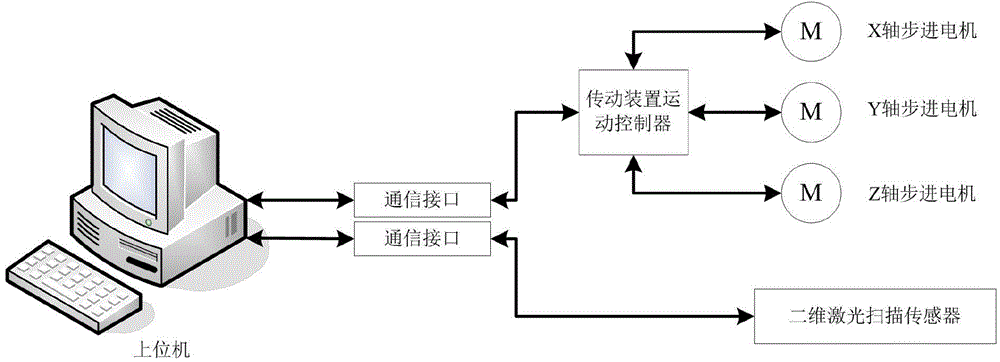

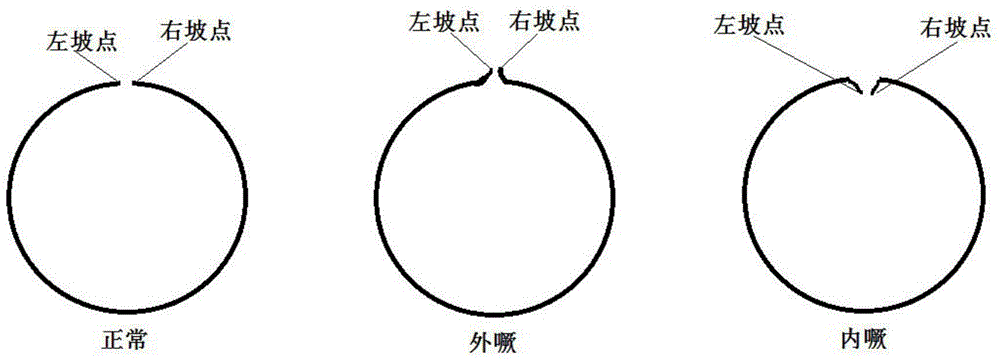

[0014] The pouting defect of the weld seam of longitudinally welded pipe is common in the production process of longitudinally welded pipe, which is made of a steel plate that is bent by pressure and then welded together. However, due to mechanical reasons or the material of the steel plate itself, the fitting of the forming seam of the welded pipe will be imperfect, resulting in the upward or downward pouting of the forming seam, which is the "pout" defect of the weld. When performing fault diagnosis on the pout of the welded pipe, if we can intuitively obtain the three-dimensional data of the welded pipe, we can calculate whether there is a defect in the position to be detected, so we need to find a way to obtain the three-dimensional data of the welded pipe.

[0015] Although the three-dimensional data of the welded pipe can be obtained by using a three-dimensional coordinate measuring instrument, this method has high environmental requirements, slow measurement speed, low m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com