Test method for corrosion- resistance performance contrast of lead-acid battery grid

A technology of lead-acid batteries and testing methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., which can solve problems such as multiple battery failure modes, grid corrosion, and inaccurate test results, and avoid test batches. Interval error, ensure accuracy, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. A comparative test method for the corrosion resistance of lead-acid battery grids, the specific scheme is as follows:

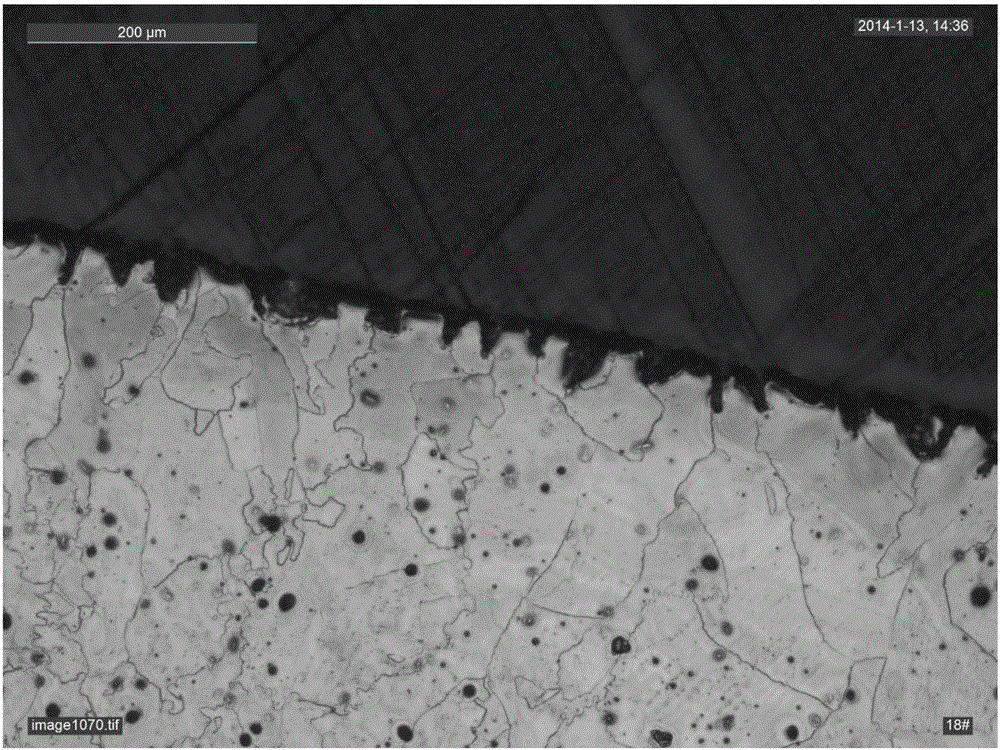

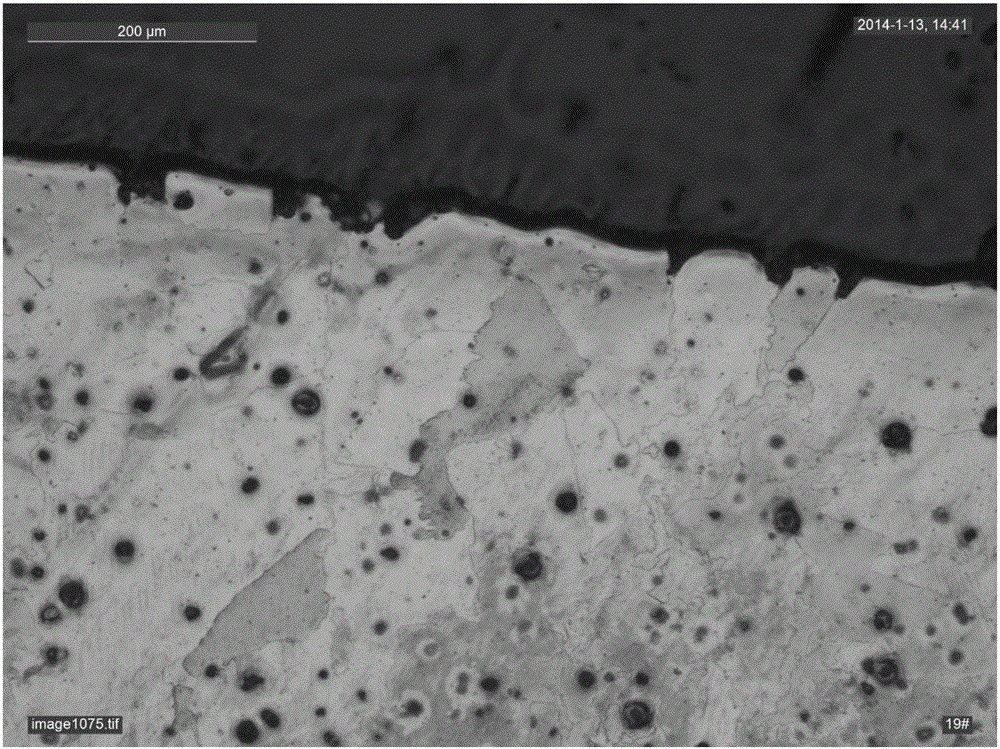

[0034] (1) Take two 6-DZM-20 grids A and B with different alloy compositions but the same production process, weigh and record the weight of a single piece. Put it into a boiled sugar-alkali solution (glucose: caustic soda: water = 1:5:50) for 10 minutes to remove surface oxides, take it out and soak it in pure water to clean it, and then dry it in a vacuum oven at 105°C for 30 minutes. The dried board The grid is weighed with an electronic balance, as the weight w of the positive grid 1A 、w 1B ;

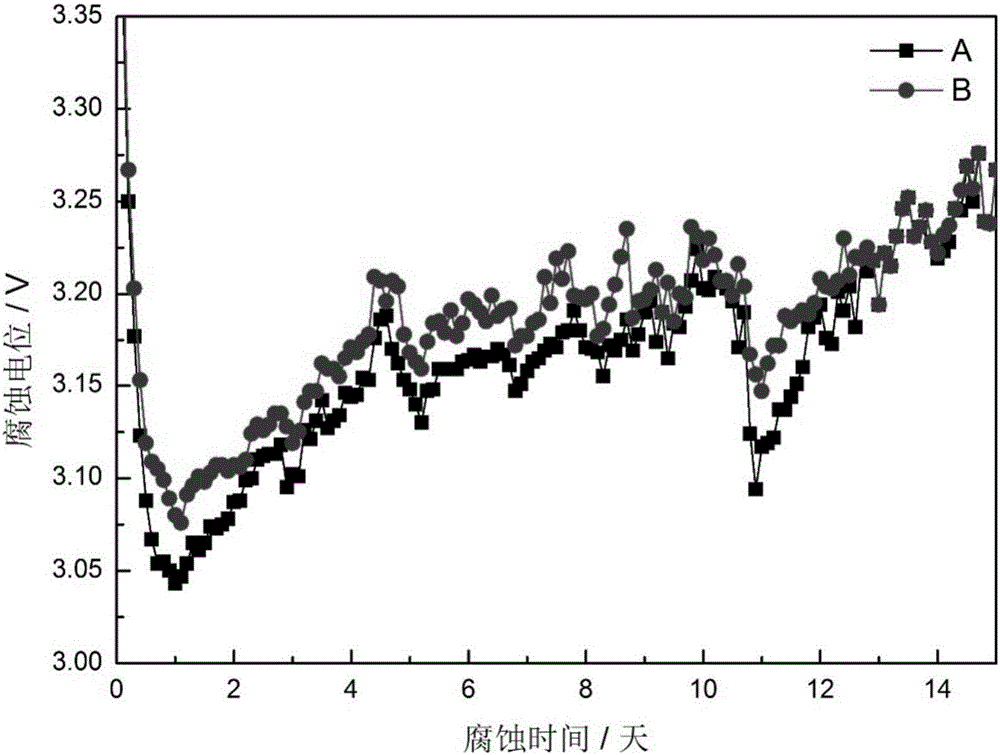

[0035] (2) Take two A grids as positive (weighed w 1A ), the negative electrode is placed in a single corrosion device a, and the distance between the two grids is kept, and the two B grids are placed in a single corrosion device b in the same way, and the positive and negative electrodes of the corrosion devices a and b are connected in series to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com