An Optimal Method for Constant Grinding Force PID Control Based on Improved Firefly Algorithm

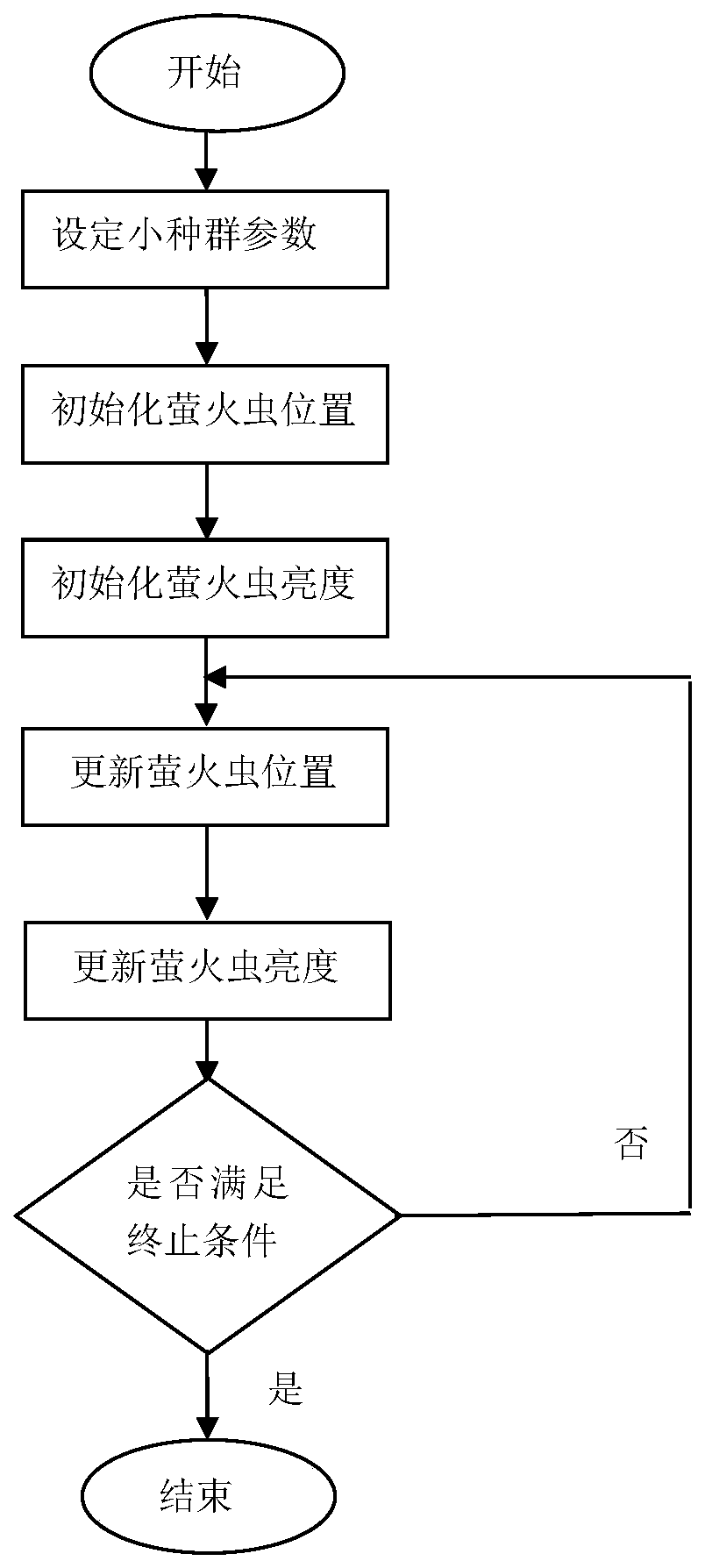

A firefly algorithm and optimization method technology, applied in the field of automatic control, can solve the problems of imperfect mathematical theory, short proposal time, slow late convergence speed, etc., and achieve the effect of excellent control ability and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The surface of the grinding wheel of the rail milling and grinding vehicle is concave, and the axis direction of the grinding wheel forms a small angle with the normal direction of the side surface of the rail. During the grinding operation, the pressure of the grinding wheel pressing down on the rail can be divided into the normal grinding force F r , Tangential grinding force F t and axial grinding force F a .

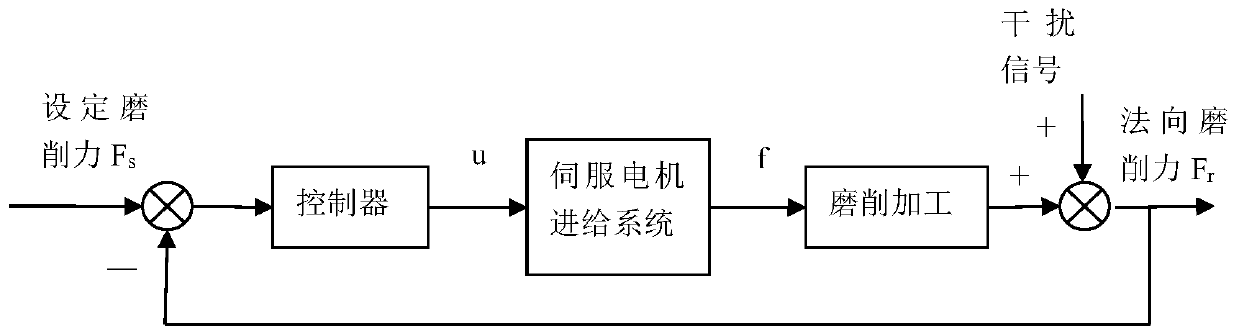

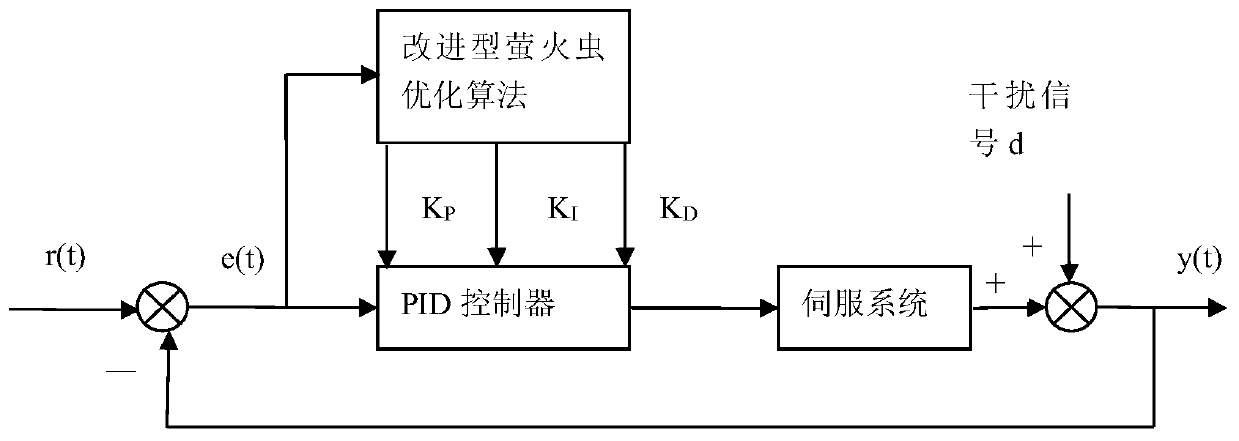

[0046] A constant grinding force PID control optimization method based on the improved firefly algorithm of the present invention is mainly aimed at the normal grinding force on the rail during the grinding operation. Such as figure 1Shown is the schematic diagram of the constant force control of the grinding force of the rail milling and grinding car. After the set grinding force passes through the controller, the servo feed system and the grinding process, a measurable normal grinding force is obtained, and the set grinding force and the normal grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com