Method for detecting non-circular gear based on coordinate method

A non-circular gear and detection method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of non-circular gear detection, etc., and achieve the effect of high detection efficiency and improved detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

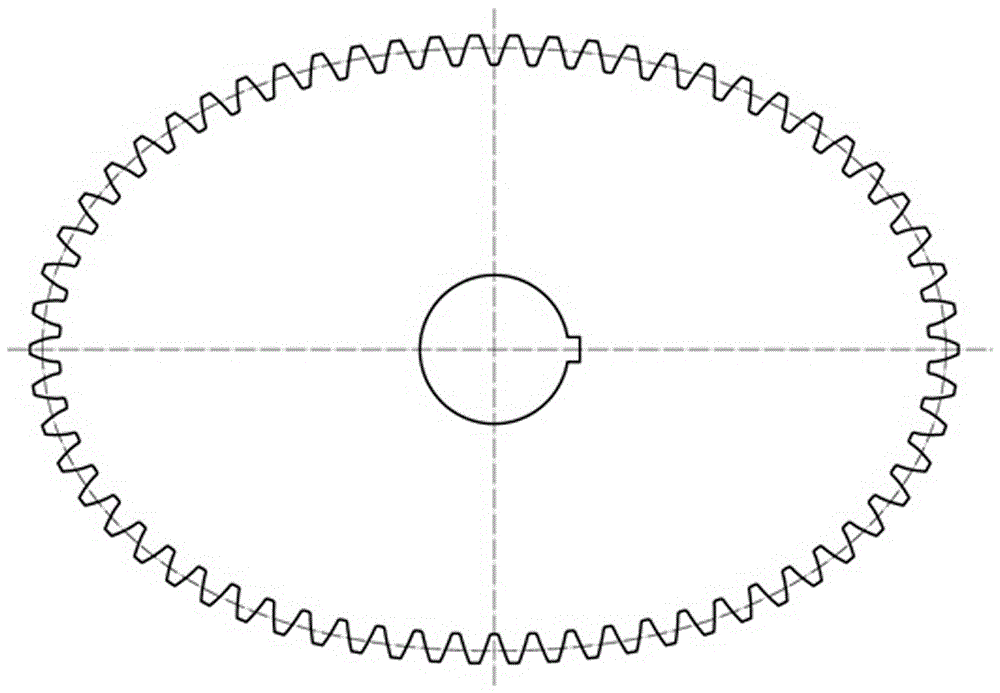

[0014] A method for detecting non-circular gears based on a coordinate method, using the following steps:

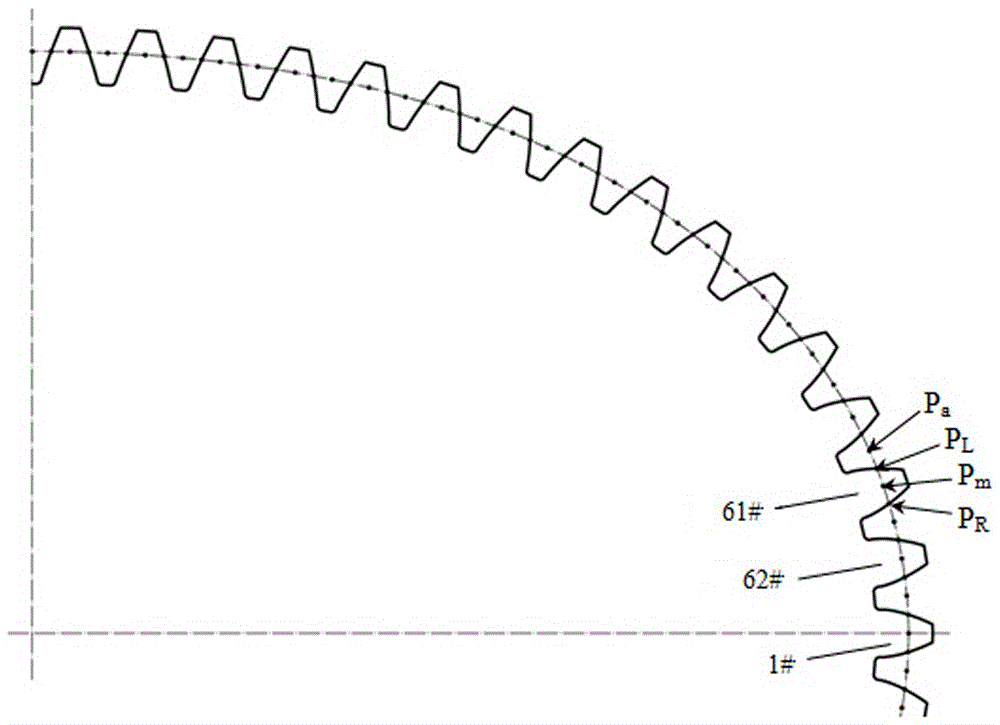

[0015] a. Collect coordinate points on the tooth profile of non-circular gears;

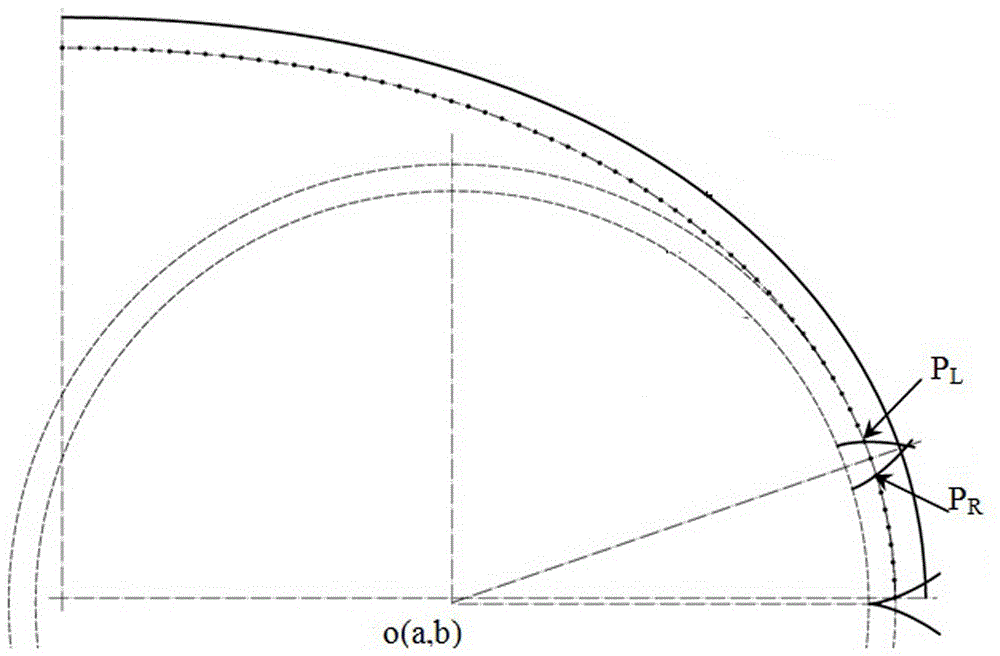

[0016] b. According to the non-circular gear pitch curve equation R=f(φ), and use Formulated as Cartesian coordinates, using the equivalent gear method to establish the curve model of the theoretical tooth profile;

[0017] c. Make the tangent line from the measured point of the tooth profile to the corresponding gear base circle, and find the length from the measured point to the tangent point, that is, the measured extension length L ai , and then find the length from the intersection point of the tangent line or the corresponding theoretical tooth profile curve along the long line to the tangent point, that is, the theoretical extension L ni , the difference between the measured span length and the theoretical span length is the deviation e of the measured point of the tooth profile f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com