Microstrip printing dipole antenna

A technology of dipole antenna and microstrip transmission line, applied in the field of communication, can solve the problem of large size of printed dipole antenna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings.

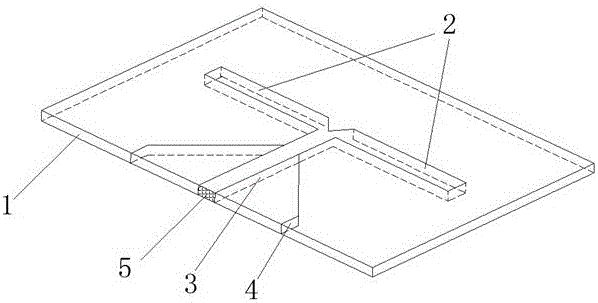

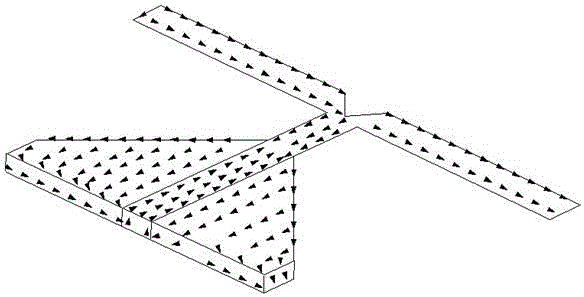

[0015] like figure 1 Shown, a kind of microstrip printed dipole antenna, this dipole antenna comprises printing plate 1, and the two sides of printing plate 1 are symmetrically attached the metal transmission line of good conductor, and metal transmission line constitutes two of described dipole antennas. arm 2, microstrip transmission line 3 and two microstrip baluns 4, the microstrip transmission line 3 is a double transmission line structure, and the two arms 2 and two microstrip baluns 4 of the dipole antenna are symmetrically arranged on the microstrip At both ends of the transmission line 3 , the microstrip balun 4 is in the shape of a right-angled trapezoid and the bottom of the trapezoid is connected to the microstrip transmission line 3 .

[0016] The end surface of the microstrip transmission line 3 located on the surface of the printing plate 1 is a wireless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com