An automatic welding device for cable joints

An automatic welding and cable joint technology, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of high cable joint welding rejection rate, low welding accuracy, low degree of automation, etc., and achieve processing The effect of low efficiency, high welding accuracy and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

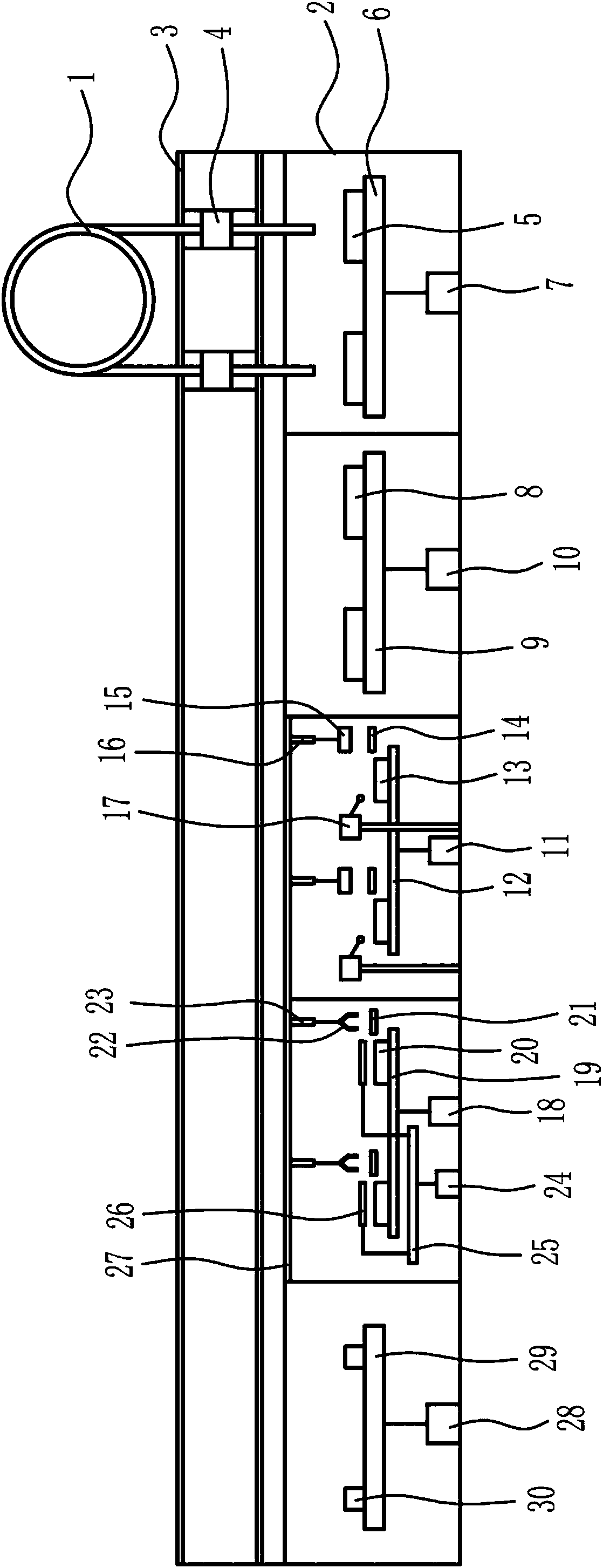

[0017]An automatic welding device for cable joints, as shown in Figure 1, includes a frame 2, a horizontal slideway I3, a wire clamping device 4, a wire stripping machine I5, a support plate I6, a cylinder I7, a wire stripping machine II8, and a support plate Ⅱ9, cylinder Ⅱ10, cylinder Ⅲ11, support plate Ⅲ12, welding table Ⅰ13, transmission device Ⅰ14, electric gripper 15, electric push rod Ⅰ16, welding device 17, cylinder Ⅳ18, support plate Ⅳ19, welding table Ⅱ20, transmission device Ⅱ21, manipulator 22. Electric push rod Ⅱ23, cylinder Ⅴ24, support plate Ⅴ25, induction coil 26, horizontal slideway Ⅱ27, cylinder Ⅵ28, support plate Ⅵ29 and detection device 30; horizontal slideway Ⅰ3 is arranged above the frame 2, and horizontal slideway Ⅰ3 There are wire clamping devices 4 symmetrically arranged on the left and right, and a wire stripping machine Ⅰ5 is installed under the wire clamping devices 4. A support plate Ⅰ6 is provided under the wire stripping machine Ⅰ5, and a cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com