Open circuit failure mode discharge tube

A failure mode, discharge tube technology, applied in the field of discharge tubes, can solve the problems of gas discharge tube short circuit, circuit board burning, affecting safe use, etc., and achieve the effect of a simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

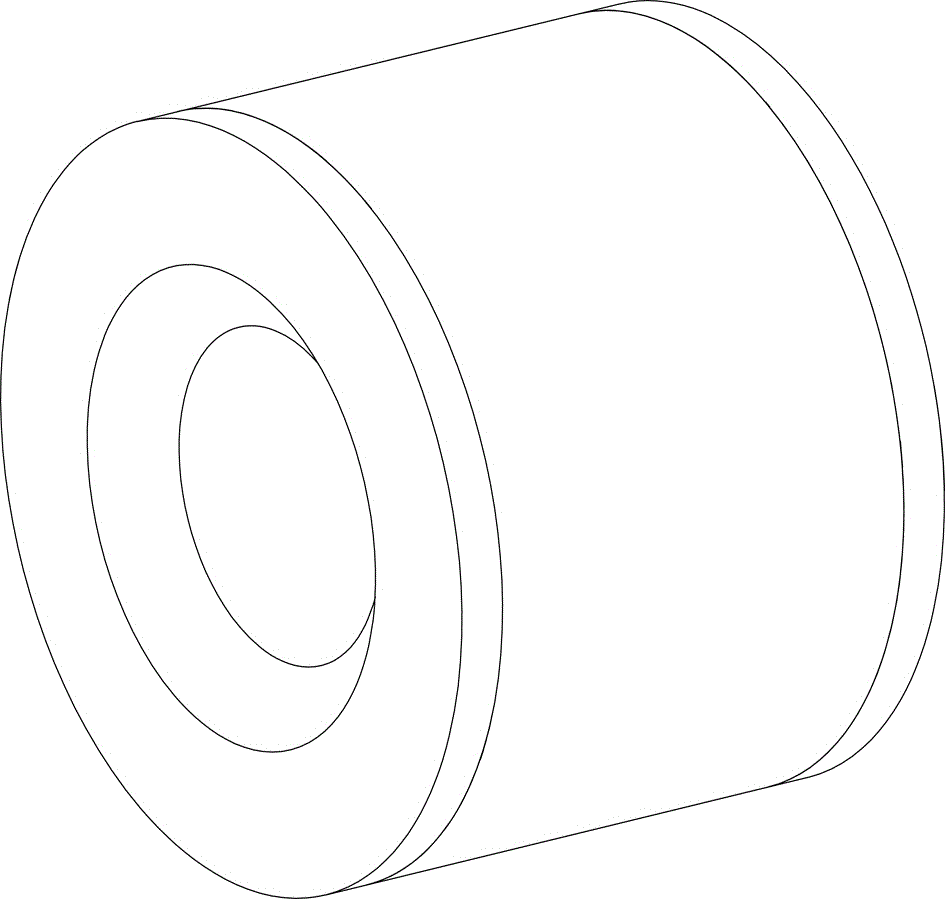

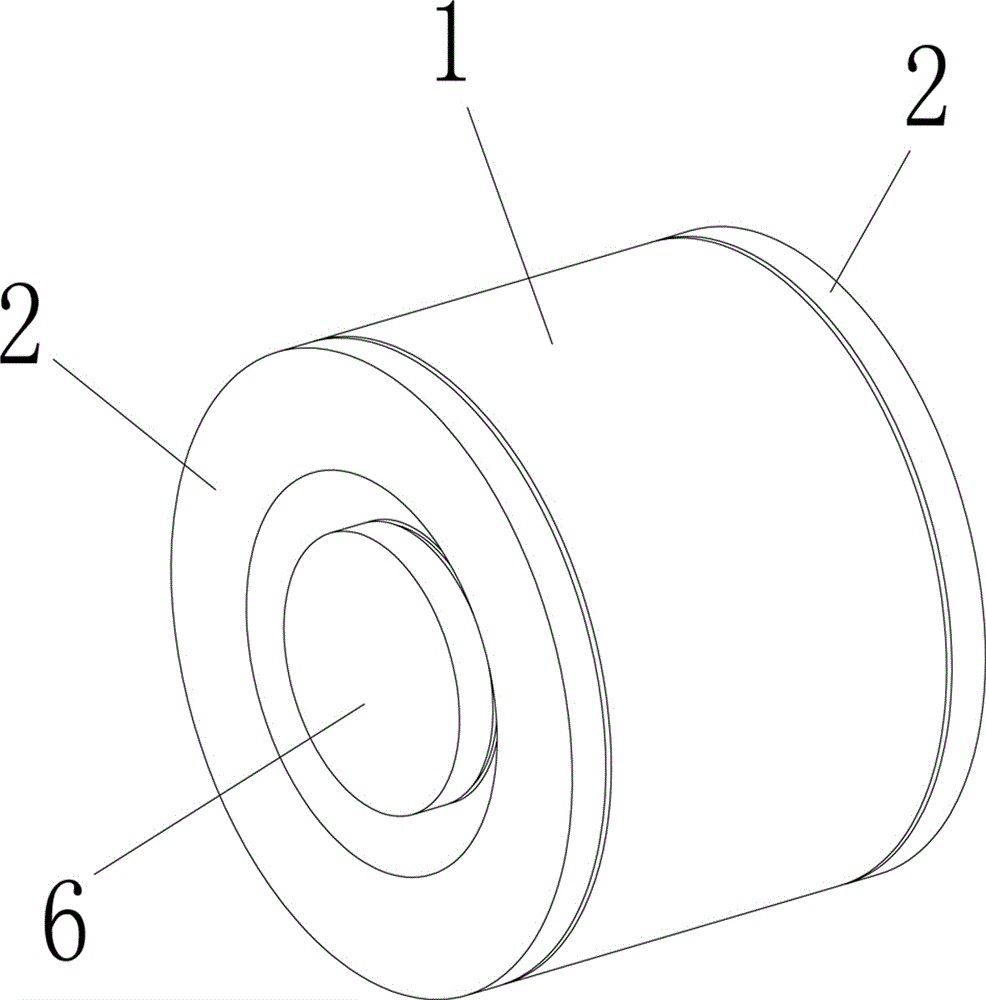

Image

Examples

Embodiment Construction

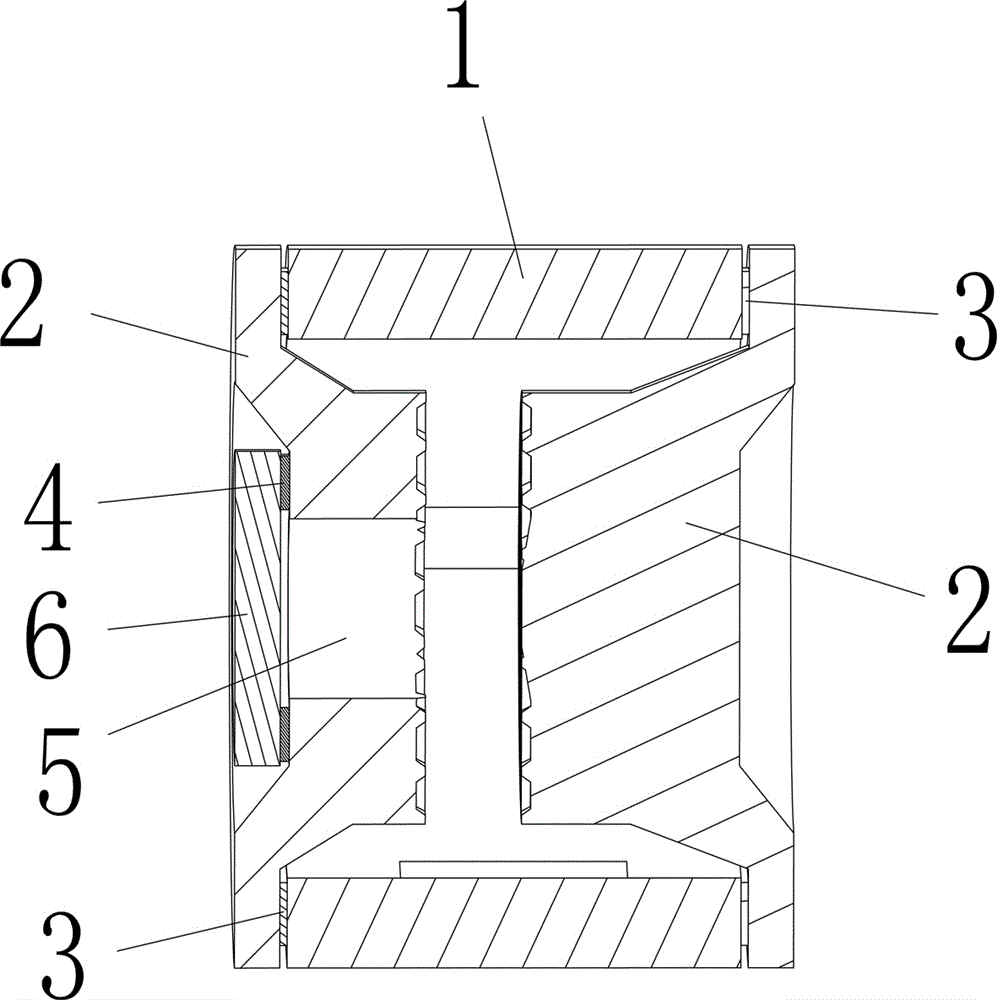

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] First of all, it should be noted that the high-temperature solder and low-temperature solder referred to in the present invention refer to the melting point of the solder, and high temperature and low temperature are relative. For the present invention, what is required is the ratio of the melting point of the solder that fixes the metal sheet to The melting point of the solder for the fixed electrode and the insulating tube body should be low, and according to different discharge tubes and the environment in which they are used, the melting point of the high-temperature solder and the low-temperature solder can be selected according to the actual situation, and will not be repeated here. Reference may also be made to the prior art in the Background Art. The high-temperature solder in the present invention may be a high-temperature solder sheet, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com