Production process of oil sump sealing strip of generator set

A production process and sealing strip technology, which is applied in the production process field of oil pan sealing strips of generator sets, can solve the problems of easy breakage, poor sealing effect at splicing parts, oil leakage and air leakage, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

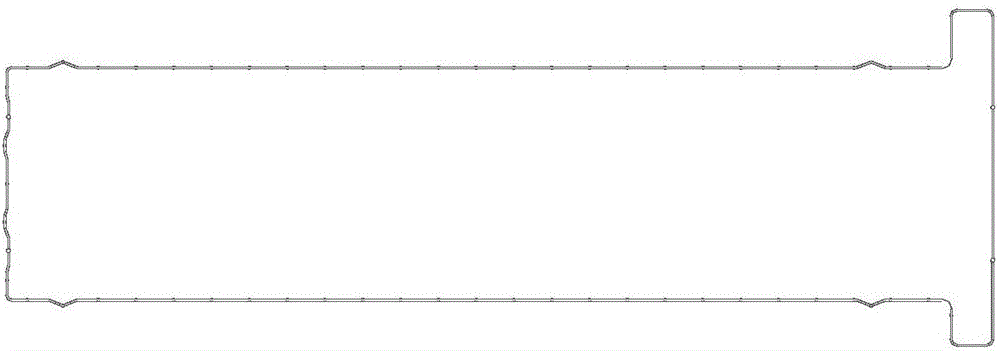

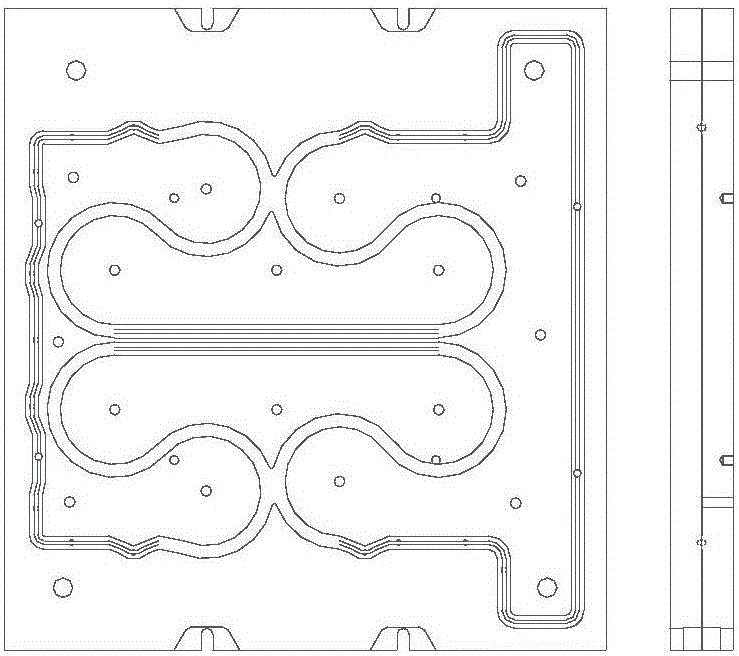

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with implementation examples and accompanying drawings.

[0022] A production process of an oil pan sealing strip, the steps are as follows:

[0023] ①Mixed rubber

[0024] Evenly disperse various compounding agents in the rubber, so that the rubber can cut short the macromolecular chain under the action of machinery, heat, chemical, etc., which is convenient for calendering and extrusion, and increases the fluidity of the molding and injection rubber material, so that the rubber material is easy to penetrate into the fiber. And it can improve the solubility and adhesion of the rubber material, so that the rubber temporarily loses its elasticity and increases the plasticity, so as to meet the technological requirements in the production process.

[0025] ② Make the die head according to the structural shape of the oil pan seal strip to be produced, and extrude the mixed rubber into a whole strip of mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com