A portable heavy-duty hoisting rope winding method

A rope-winding, heavy-duty technology, which is applied in the field of ships and ocean engineering, can solve the problems of difficult control of the length of the wire rope, too many shackles to arrange the hook, and the limited diameter of the wire rope, so as to achieve the advantages of small wear, large contact area and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

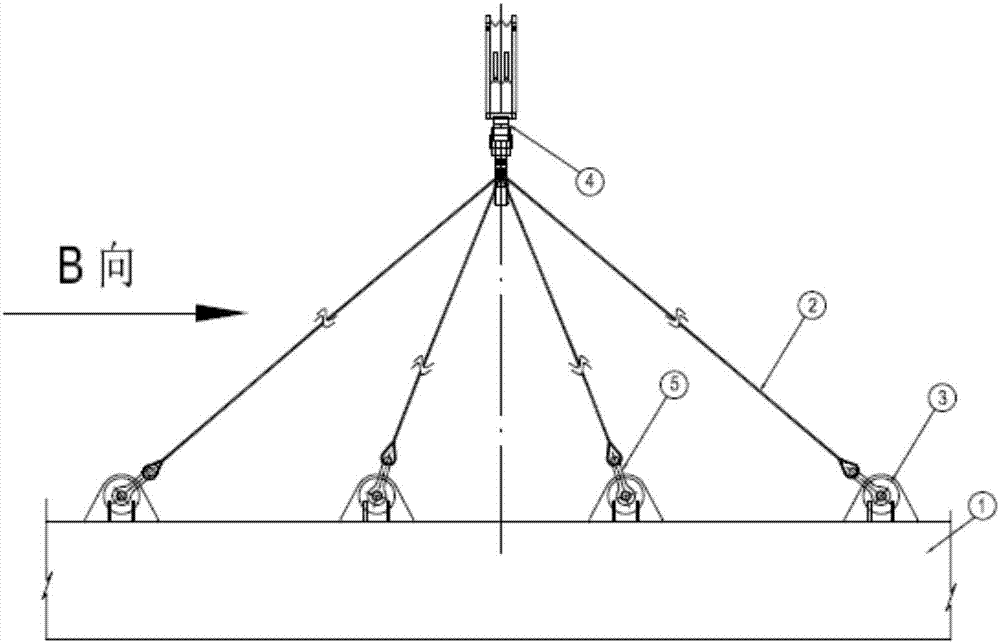

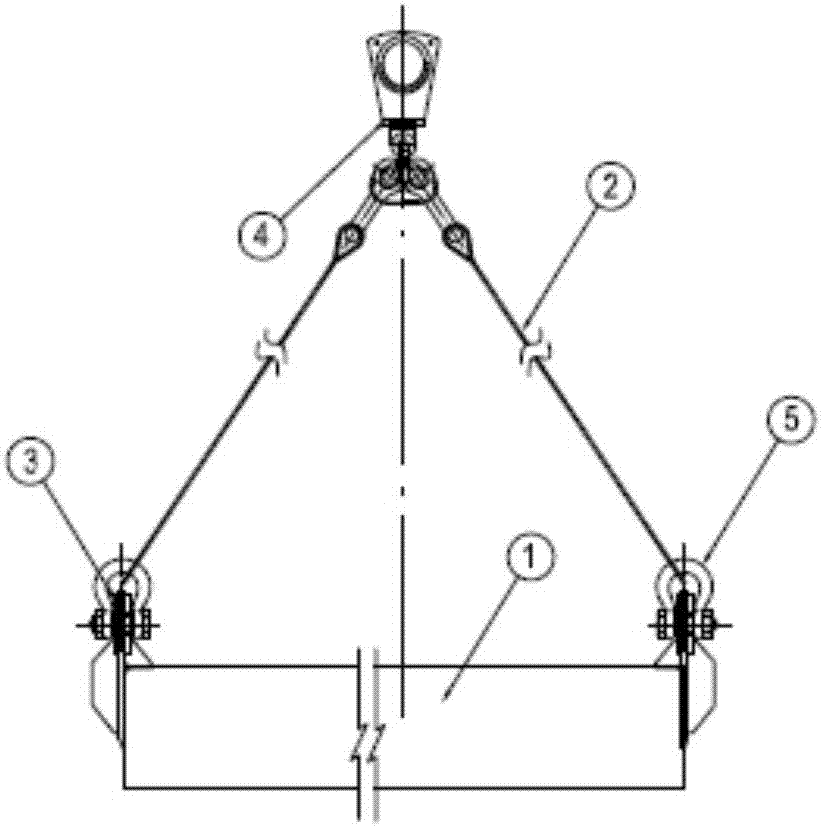

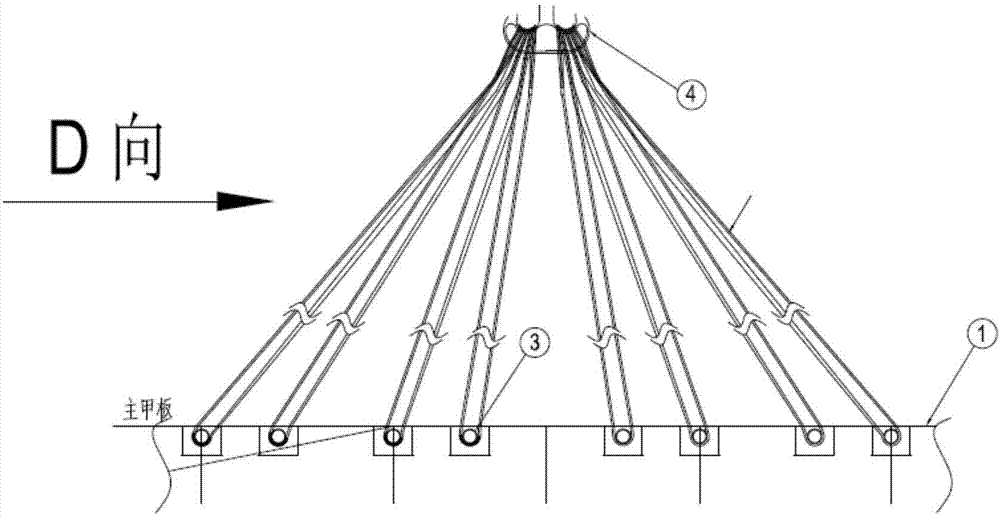

[0033] Such as image 3 with 4 As shown, the portable heavy lifting rope winding method of this embodiment includes the following steps:

[0034] Step 1. Preparatory work, one hoisting steel rope and no less than one hoisting point steel pipe; the hoisting point steel pipe is located under the main deck of the barge and the hoisting point steel pipes are arranged side by side from bow to stern; in this step, the hoisting rope is 2 windings The steel pipe passing the lifting point is hooked on the hook 4 used for the lifting test, and the steel pipe 3 of the lifting point is located below the main deck of the barge (the weight being lifted). The number of hanging point steel pipes 3 can be determined according to actual operation requirements. The lifting point steel pipe 2 is arranged on the main structure of the barge and is integrally formed.

[0035] Step 2. Fix one end of the hoisting wire rope on the crane hook; this step is to fix the "pipa head" at the head end of the hoist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com