Novel weave rapier loom

A rapier loom, a new type of technology, is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems of gaps in the weft, uneven density, and low degree of cooperation between warp and weft, and achieve stable power output and uniform movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

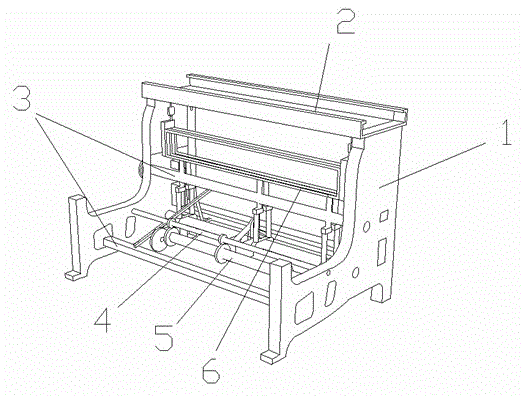

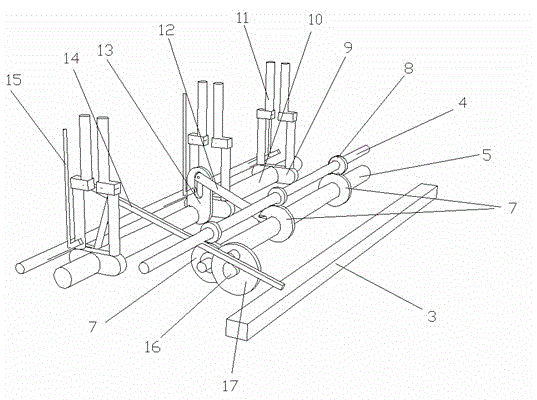

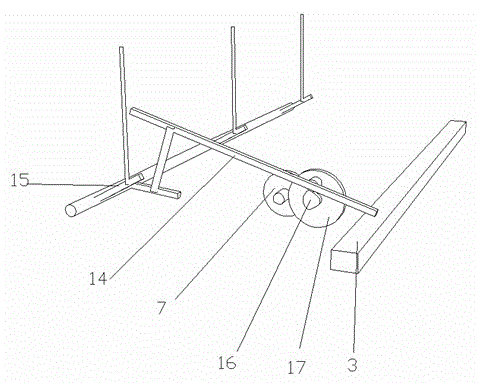

[0020] Please refer to the attached figure 1 ( figure 2 , 3 , 4, 5), the present invention is a twisted rapier loom, which consists of frame 1, top frame 2, frame connecting rod 3, input shaft 4, output shaft 5, heald frame 6, output shaft gear 7 , input shaft gear 8, beating-up rod connecting part 9, beating-up shaft 10, beating-up drive rod 11, swing arm rod 12, swing arm connecting part 13, cam swing arm 14, rear bracket 15, cam 16, cam drive gear 17 compositions.

[0021] Wherein, the frame 1, the top frame 2 and the frame connecting rod 3 are combined to form the main frame structure of the present invention to support the whole equipment; the input shaft 4, the output shaft 5, the heald frame 6, the output shaft gear 7 , input shaft gear 8, beating-up rod connecting part 9, beating-up shaft 10, beating-up drive rod 11, swing arm rod 12, swing arm connecting part 13, cam swing arm 14, rear bracket 15, cam 16 and cam transmission gear 17 are connected to each other as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com