Road cross section structure of mountainous road

A construction and highway technology, applied in the field of road section structure of winding mountain highways, can solve the problems of highway overturning downhill cliffs, slab suspension ruptures, and more concrete needs, so as to improve safety and comfort, enhance road bearing capacity, and save concrete. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

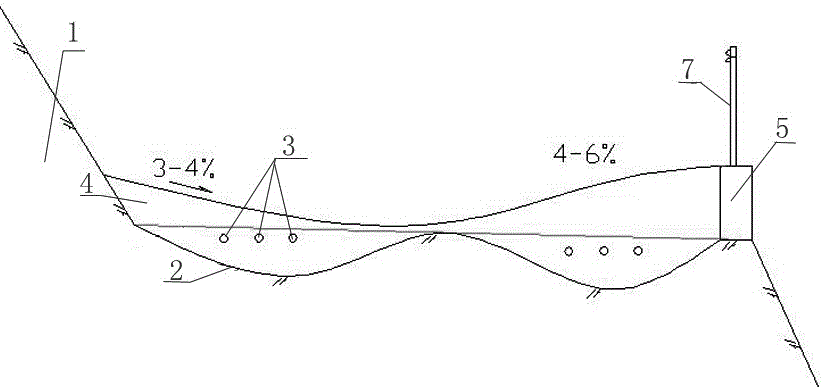

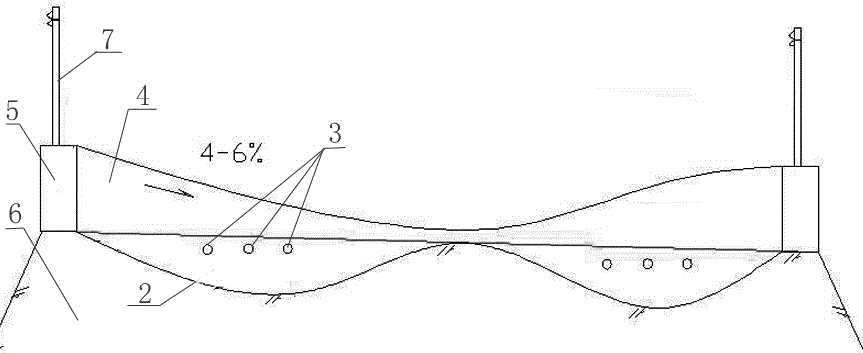

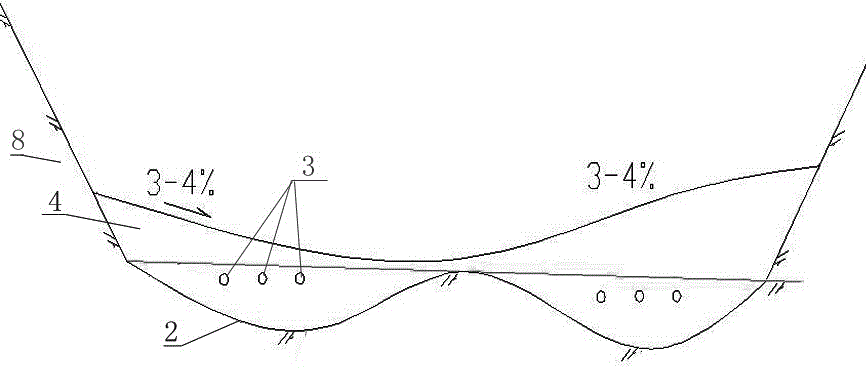

[0025] The present invention as figure 1 / 2 / 3 shown.

[0026] A road cross-section structure for mountainous roads. The road cross-section structure of mountainous roads includes road grooves. Concrete road surface layer 4 is poured on top, wherein the concrete road surface layer 4 is a streamlined groove-like structure with high concave on both sides, and the pavement base 2 and concrete road surface layer 4 finally form a cross-sectional structure of "∞".

[0027] The "∞" cross-section of the road base 2 and the concrete road surface 4 is constructed in the slope section of the curve, and steel bars 3 are added longitudinally in the concrete road surface 4 to strengthen the strength of the road surface. drain.

[0028] In the mountain road, one side is the hillside side wall, and the other side is the steep slope and steep cliff structure 1, the concrete road surface layer 4 of the hillside side wall is naturally connected with the slope surface, and the rainwater is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com