Patch type luminous bulb with semi-circular heat radiation ring and application thereof

A heat radiation, patch-type technology, applied in the field of LED lighting, can solve problems such as systemic defects, achieve the effect of improving heat radiation efficiency, low difficulty and cost, and easy promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

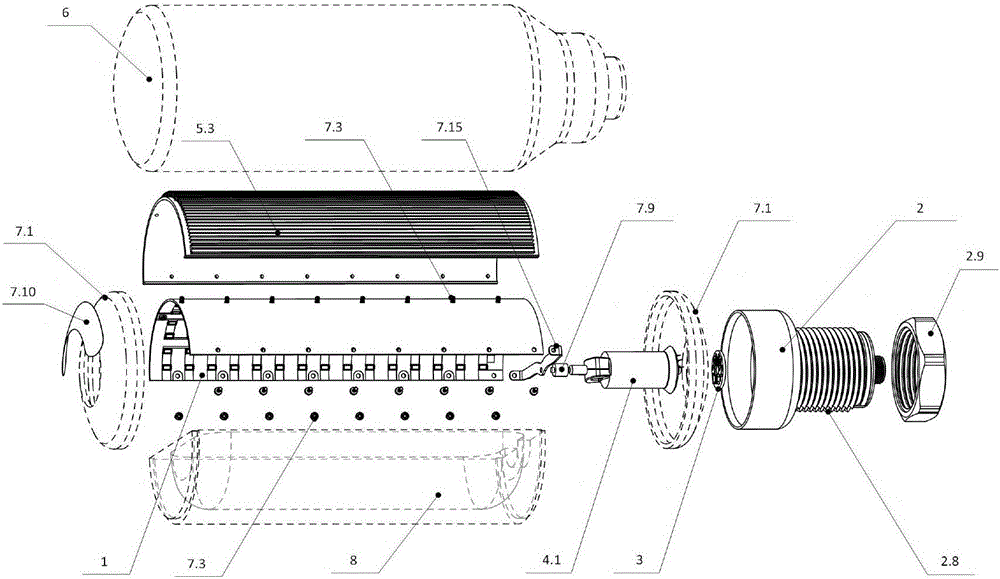

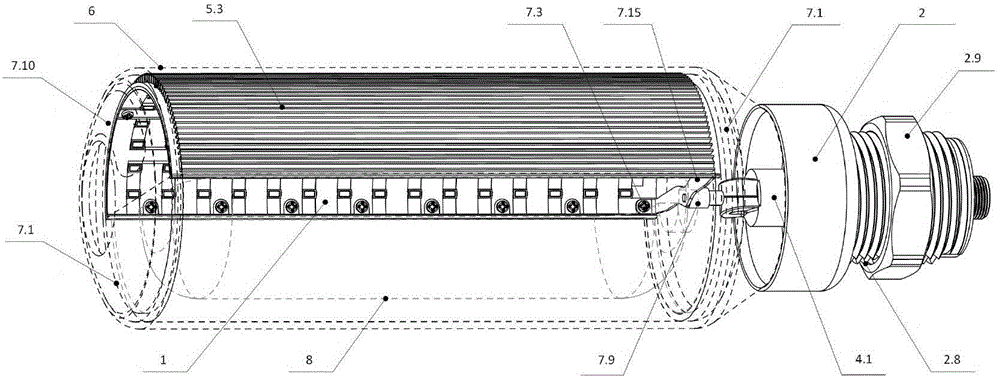

[0036] Example 1. A patch-type light bulb (arc-shaped light-emitting component) with a semicircular heat radiation ring, such as figure 1 and 2 As shown, it includes a lamp cap assembly 2 with a drive assembly 3, and the lamp cap assembly 2 is connected to the bulb shell 6. A heat radiation ring 5.3 with a semicircular section is provided inside the bulb shell 6, and a sticker is provided on the heat radiation ring 5.3. For the light-emitting component 1 of the chip LED chip, a lead bracket 4.1 is arranged in the bulb shell 6, and a plurality of electrical connecting wires 4.2 connected to the driving component 3 are arranged on the lead bracket 4.1; The heat radiation ring 5.3 is an extruded profile; the convex surface of the heat radiation ring 5.3 is close to the bulb shell 6, the distance between the heat radiation ring 5.3 and the bulb shell 6 is reduced as much as possible, and fins are provided to increase the heat uniformity and heat radiation area . The bulb shell ...

Embodiment 2

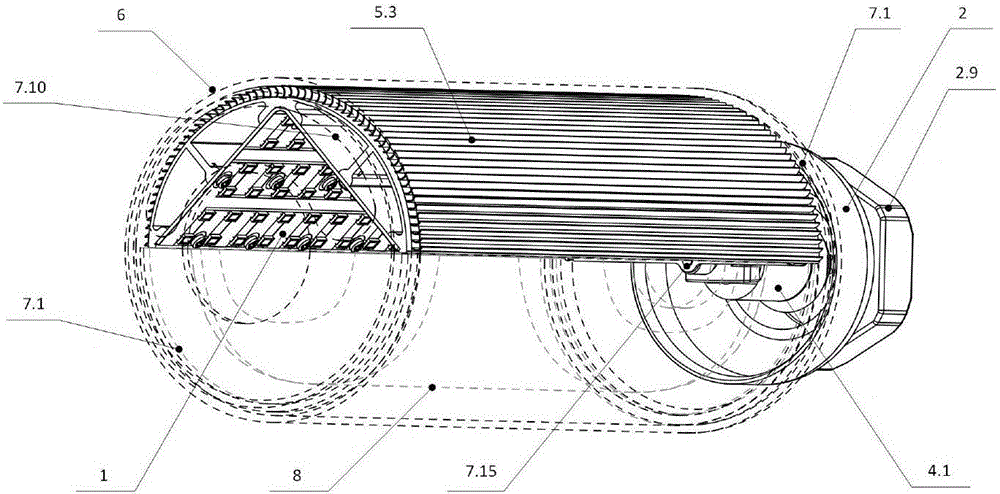

[0037] Example 2. A patch-type light bulb (V-shaped light-emitting component) with a semicircular heat radiation ring, such as image 3 As shown, it includes a lamp cap assembly 2 with a drive assembly 3, and the lamp cap assembly 2 is connected to the bulb shell 6. A heat radiation ring 5.3 with a semicircular section is provided inside the bulb shell 6, and a sticker is provided on the heat radiation ring 5.3. For the light-emitting component 1 of the chip LED chip, a lead bracket 4.1 is arranged in the bulb shell 6, and a plurality of electrical connecting wires 4.2 connected to the driving component 3 are arranged on the lead bracket 4.1; The heat radiation ring 5.3 is an extruded profile; the convex surface of the heat radiation ring 5.3 is close to the bulb shell 6, the distance between the heat radiation ring 5.3 and the bulb shell 6 is reduced as much as possible, and fins are provided to increase the heat uniformity and heat radiation area . The bulb shell 6 is a tu...

Embodiment 3

[0038] Example 3. A patch-type light bulb (flat light-emitting component) with a semicircular heat radiation ring, such as Figure 4 As shown, it includes a lamp cap assembly 2 with a drive assembly 3, and the lamp cap assembly 2 is connected to the bulb shell 6. A heat radiation ring 5.3 with a semicircular section is provided inside the bulb shell 6, and a sticker is provided on the heat radiation ring 5.3. For the light-emitting component 1 of the chip LED chip, a lead bracket 4.1 is arranged in the bulb shell 6, and a plurality of electrical connecting wires 4.2 connected to the driving component 3 are arranged on the lead bracket 4.1; The heat radiation ring 5.3 is an extruded profile; the convex surface of the heat radiation ring 5.3 is close to the bulb shell 6, the distance between the heat radiation ring 5.3 and the bulb shell 6 is reduced as much as possible, and fins are provided to increase the heat uniformity and heat radiation area . The bulb shell 6 is a tubul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com