Servo system control method for five-shaft linked numerically controlled machine tool

A technology of CNC machine tools and servo systems, applied in the field of CNC, can solve the problems of complex contour shape, non-linear trajectory, single axis cannot effectively reduce contour error, etc., and achieve the effect of good tracking performance and contour performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

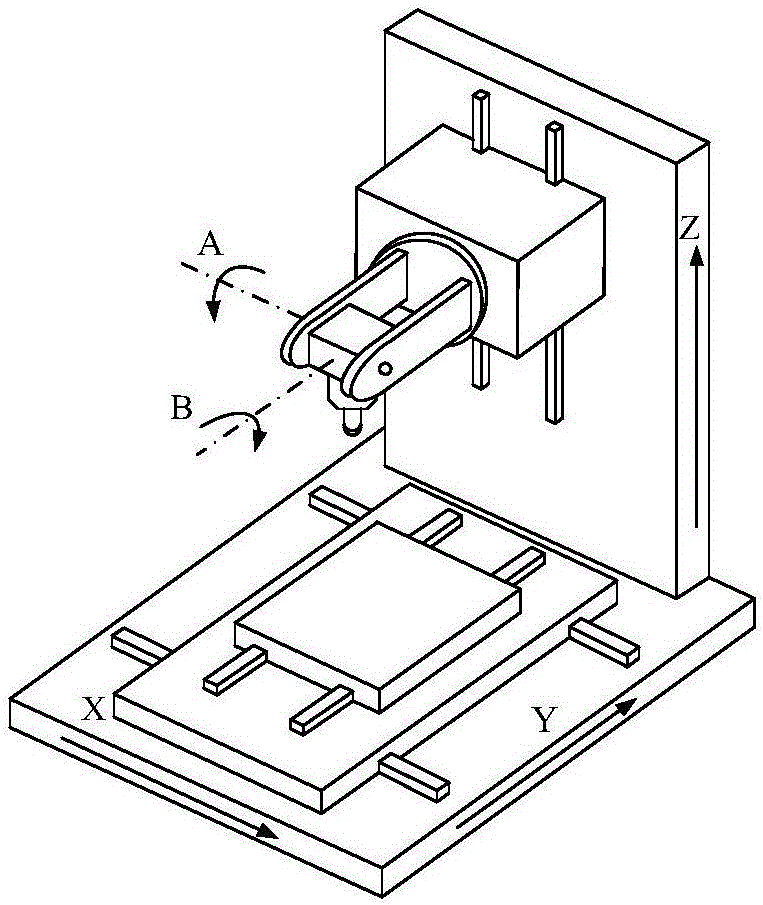

[0045] The structure of the spindle swing type five-axis linkage CNC machine tool adopted in this embodiment is as follows: figure 1 As shown, it includes five feed axes: three linear coordinate axes X, Y, Z and two rotational coordinate axes A, B, and the two rotational coordinate axes A and B are on the main shaft, rotating around the X and Y axes respectively .

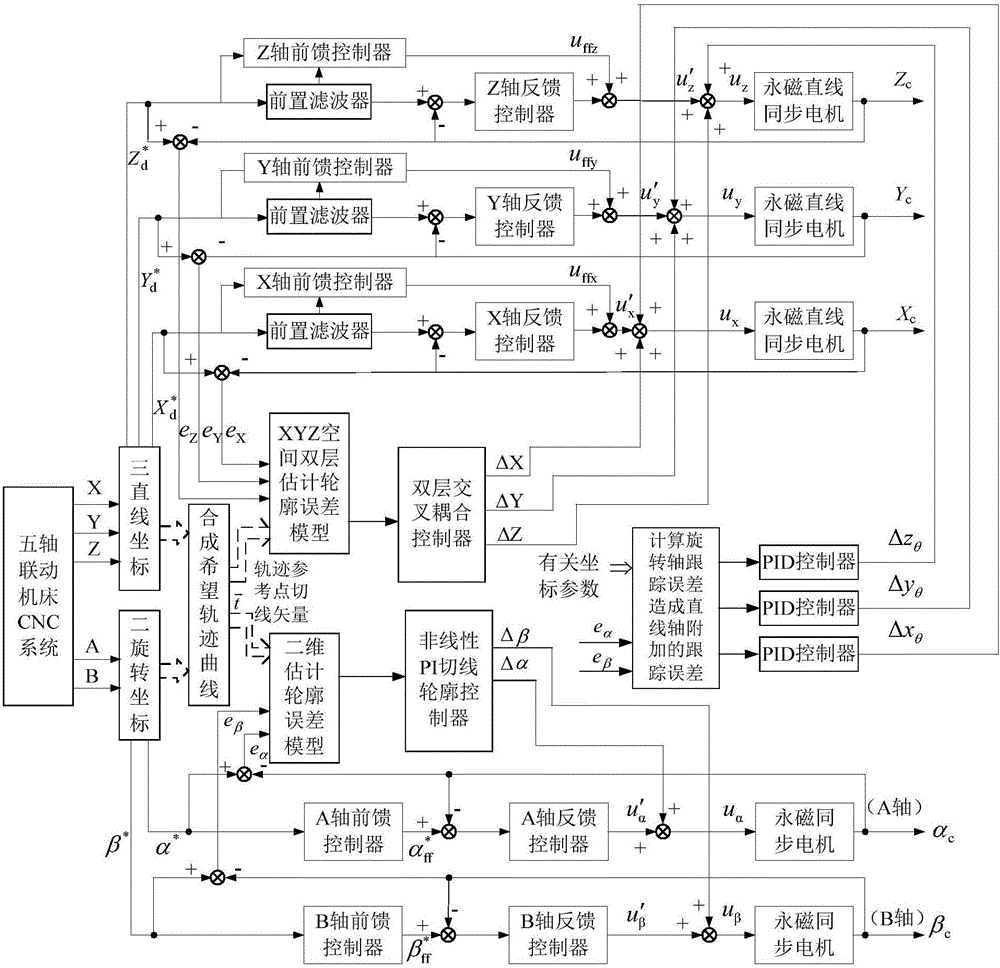

[0046] The schematic diagram of the control principle of the servo system control method of the five-axis linkage CNC machine tool is as follows: figure 2 As shown, the five-axis linkage CNC machine tool servo system obtains the ideal position signal X of the X, Y, Z, A, and B axes d * , Y d * ,Z d * 、α * , β * . Ideal position signal α of A and B axes * , β * After feedforward control and feedback control, the input control signal u of the A and B axes is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com