Electric power work onsite safety control system and realization method thereof

A work site, safety control technology, applied in the electronic field, can solve the problems of high danger in the power construction and maintenance site, accidental contact with live equipment, personal electric shock accidents, etc., to prevent unfinished operations or permit line errors, and prevent accidental contact with live electricity Equipment, the effect of eliminating license errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

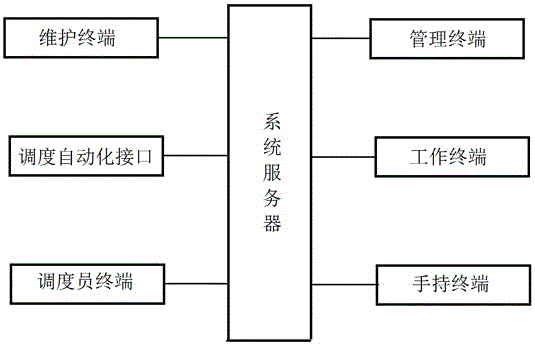

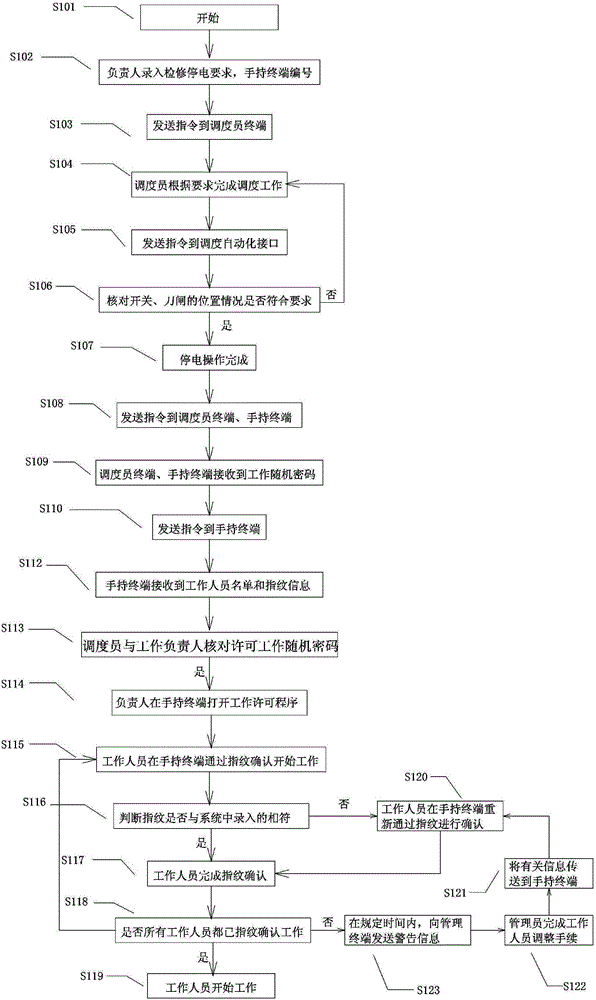

[0053] Example 1, such as figure 1 As shown in the figure, a safety management and control system for an electric power work site is composed of a system server, a maintenance terminal, a dispatcher terminal, a work terminal, a management terminal, a handheld terminal, and a dispatch automation interface.

[0054] The person in charge of the work enters the names and fingerprint information of the members of the work class through the work terminal before working.

[0055] The system server communicates with the substation monitoring system through the dispatching automation interface, and collects position signals of switches, switches, and grounding switches in the substation.

[0056] The handheld terminal communicates with the system server through the telecommunications wireless network.

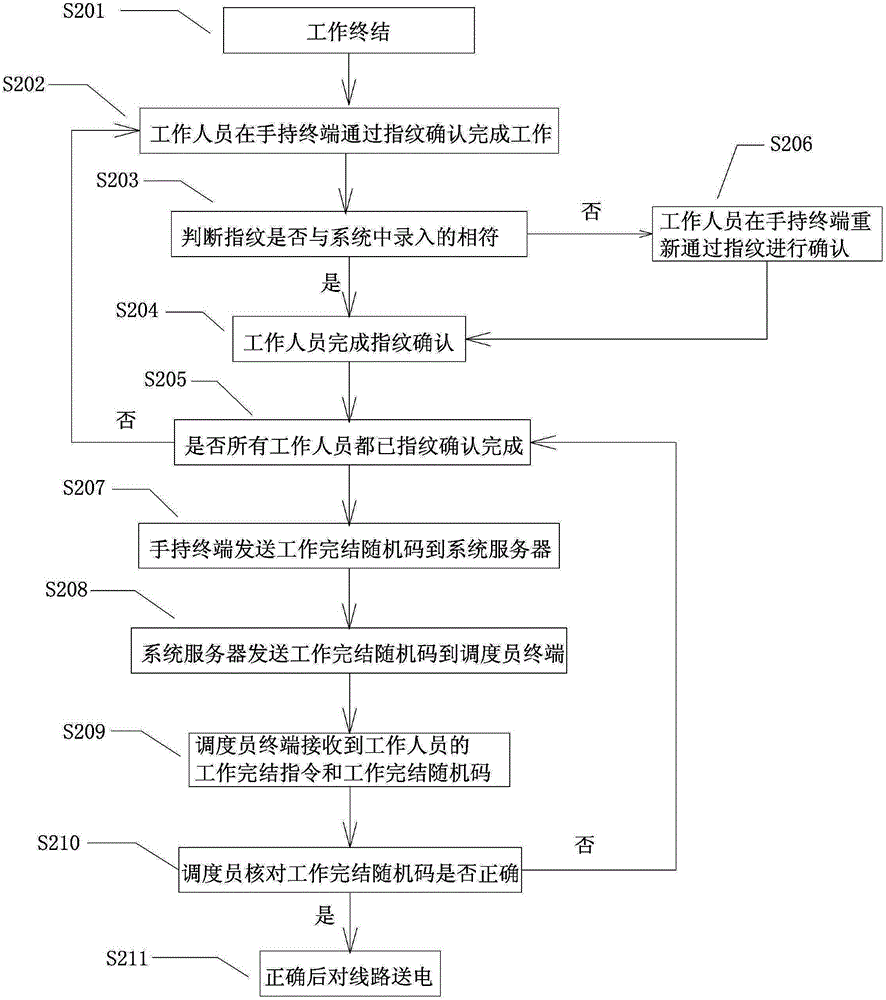

[0057] The implementation method of the on-site safety management and control system of the present invention is to eliminate the dispatcher's permission error and power transmission e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com