Ultrasonic motor servo control system speed dead zone compensation control device and method

A technology of servo control system and ultrasonic motor, applied in control system, AC motor control, estimation/correction of motor parameters, etc., can solve problems such as speed dead zone, cycle repetition signal control error, system performance impact, etc., to reduce The degree of influence, the effect of improving control efficiency and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

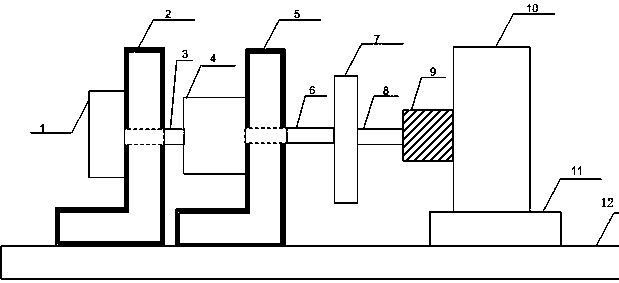

[0019] The ultrasonic motor control system of the present invention, such as figure 1 As shown, it includes a base 12 and an ultrasonic motor 4 arranged on the base 12, the output shaft 3 of the ultrasonic motor 4 is connected to the photoelectric encoder 1, and the output shaft 6 on the other side is connected to the flywheel inertial load 7 , the output shaft 8 of the flywheel inertial load 7 is connected to the torque sensor 10 through the elastic coupling 9, and the signal output end of the photoelectric encoder 1 and the signal output end of the torque sensor 10 are respectively connected to the control system. The control system includes a speed dead zone compensation controller.

[0020] The ultrasonic motor 4 , photoelectric encoder 1 and torque sensor 10 are respectively fixed on the base 12 via the ultrasonic motor fixing bracket 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com