A corner drive system

A driving system and turning angle technology, which is applied in the directions of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve the problems of low repeated positioning accuracy, low positioning accuracy, low positioning speed, and low positioning accuracy, so as to improve the positioning speed and repeatability. Positioning accuracy, reducing repeated positioning error, and the effect of low error

Inactive Publication Date: 2012-10-17

HARBIN DONGAN ENGINE GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

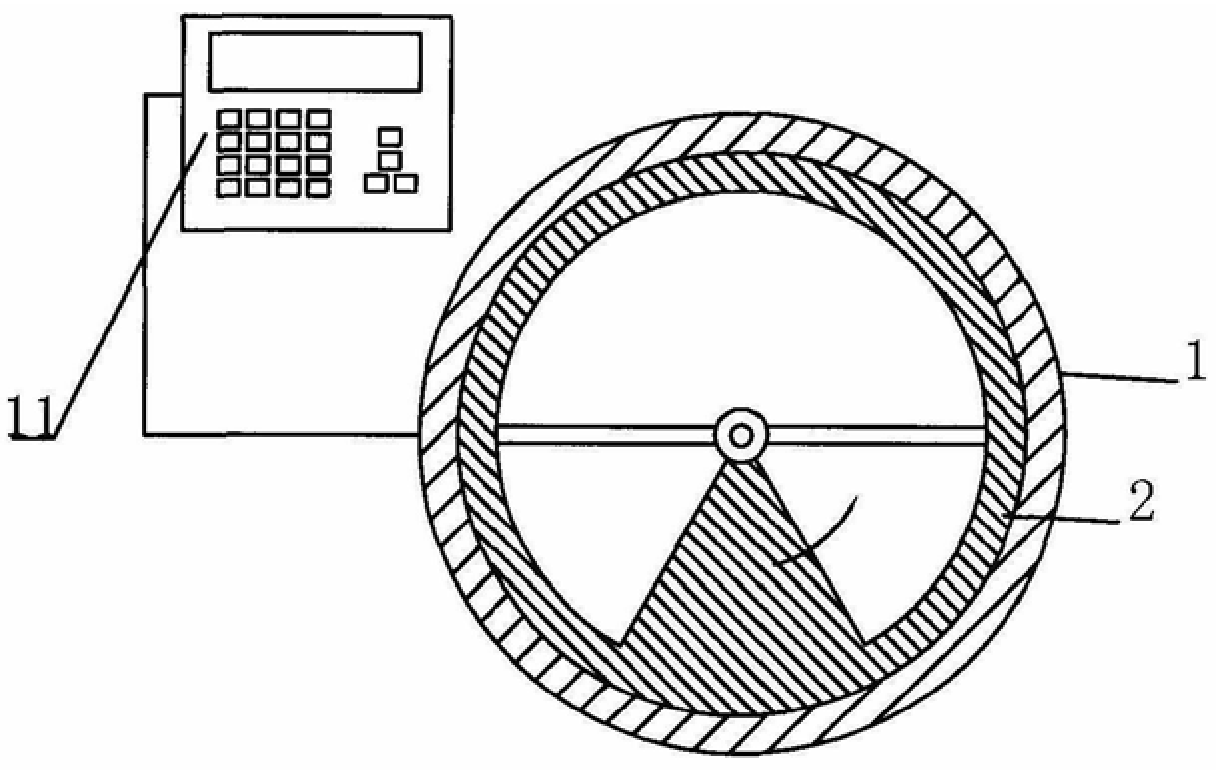

When in use, the controller sends signals to the motor and the angular displacement sensor, the motor drives the circular moving plate to rotate, the angular displacement sensor judges whether the rotation angle matches the signal requirements, and feeds back to the controller, thus forming a closed-loop control system. Accuracy is limited, its positioning accuracy is not high (1%-5%), and due to the characteristics of feedback control, its positioning speed is low, and its repeat positioning accuracy is not higher than that of positioning accuracy

In addition, the motor and angular displacement sensor of this system are arranged at the center of the circle, which will block the air intake and affect the test effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

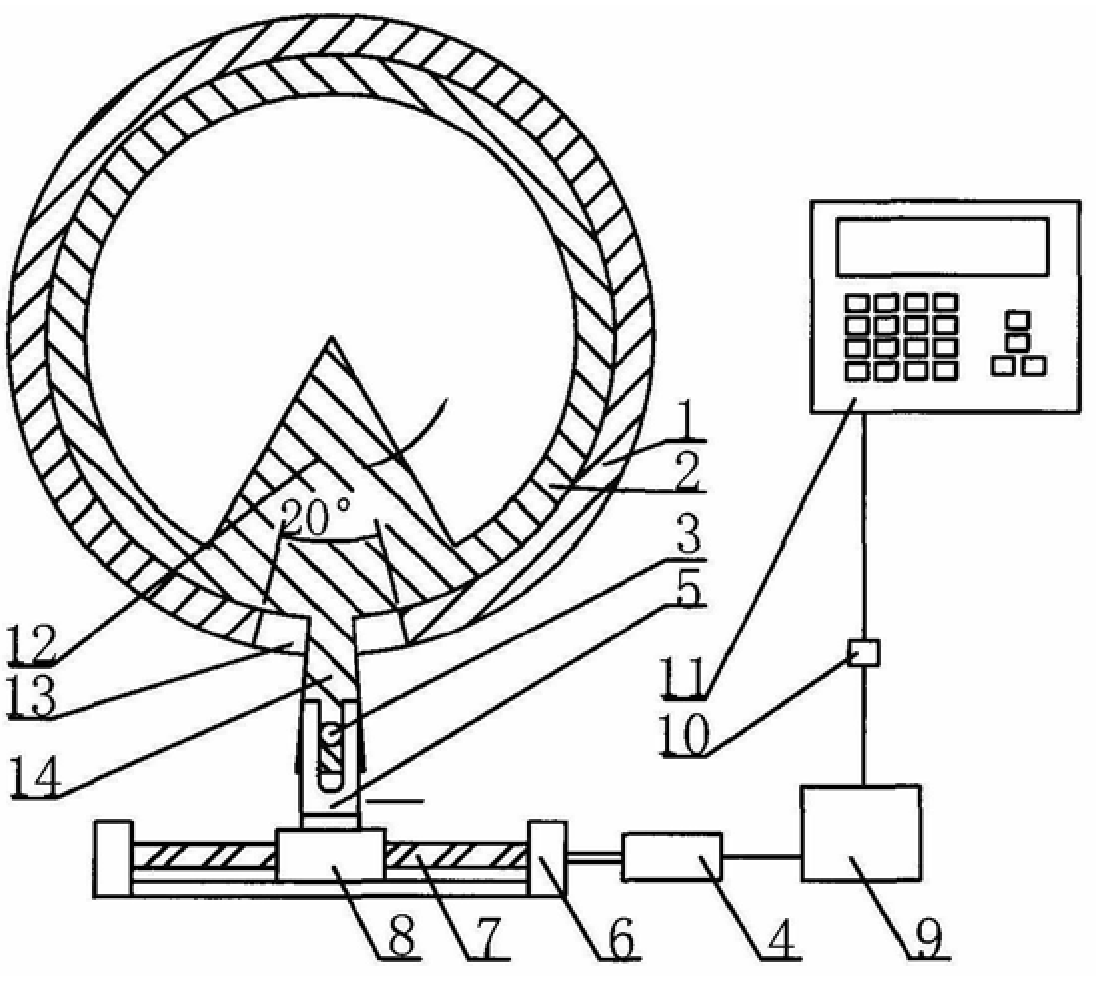

The invention relates to a high-precision small-angle rotational angle drive system for small turbofan engine tests. The invention utilizes the idea of approximating the small rotation angle by the micro displacement, changes the direct control of the rotation into the control of the linear motion, and uses the linear motion to generate the corresponding rotation angle, so as to achieve the effect of indirectly controlling the rotation angle. At the same time, the whole system is open-loop control, which makes each movement relatively independent, reduces the repeated positioning error of the system, improves the positioning speed and repeated positioning accuracy, and at the same time, the error is low compared with the traditional structure. According to the calculation, the theoretical design accuracy reaches 0.13% , within the range of the rotation of the annular moving plate, the theoretical design accuracy does not exceed 0.05%, and the repeatability error is controlled within 0.5%; the accuracy is higher than that of the traditional corner drive system, and there is no excess air in the flow channel that blocks the engine. The structure will not cause clogging.

Description

A corner drive system technical field The invention relates to a high-precision small-angle rotation angle driving system used for small turbofan engine tests. Background technique The existing angular drive system for engine testing uses a closed-loop system composed of a motor and an angular displacement sensor. As shown in Figure 1, the structure of the traditional angular drive system with the angular displacement sensor as the core is set up in a ring-shaped flow tube with an annular cross-section. The bracket is installed with a motor at the center of the circle, and the center of the circle of the fan-shaped annular moving piece with a spoiler placed in the flow tube is fixedly connected with the output shaft of the motor, and the angular displacement sensor is installed on the motor. When in use, the controller sends signals to the motor and the angular displacement sensor, the motor drives the circular moving plate to rotate, the angular displacement sensor judges...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02C9/00

Inventor 李永佳张松涛陈伦海王学斌黄大鹏

Owner HARBIN DONGAN ENGINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com