Revolving support mechanism applied to shot blasting for inner wall of steel tube

A shot blasting cleaning and slewing support technology, which is applied to used abrasive treatment devices, abrasive jet machine tools, abrasives, etc., can solve the problems of inability to effectively ensure lubrication and sealing effect, inconvenient processing and assembly, and poor sealing performance. Achieve outstanding substantive features, compact structure, good sealing and lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

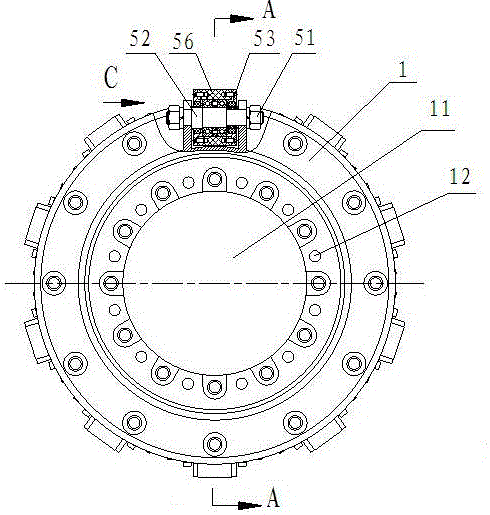

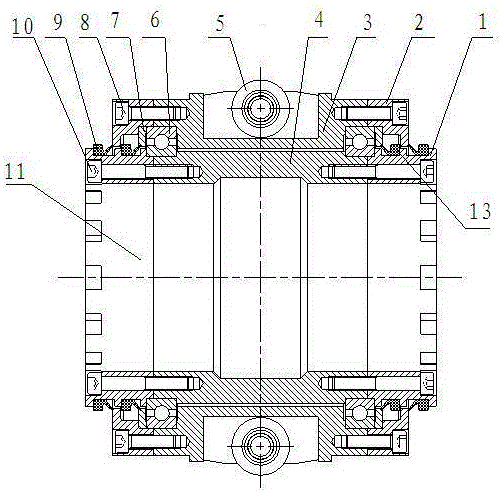

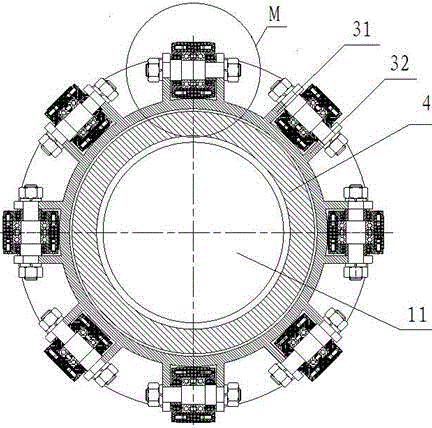

[0027] Specific implementation methods: such as Figure 1~Figure 6 As shown, the present invention provides a rotary support mechanism applied to shot blasting on the inner wall of steel pipes, including rolling parts in the circumferential direction and rolling parts in the axial direction, wherein the rolling parts in the circumferential direction include supporting inner rings 4, inner retaining rings 1, The supporting outer ring 3, the outer retaining ring 2 and the rolling bearing 6, the inner retaining ring 1 are respectively installed on the left and right sides of the supporting inner ring 4, and are fixedly connected by hexagon socket bolts 10; the outer retaining ring 2 is respectively installed on the supporting outer ring 3 The left and right sides are fixedly connected by hexagon socket bolts 8. One end of the rolling bearing 6 away from the supporting inner ring 4 is provided with a bearing retaining ring 7 , one end face of the bearing retaining ring 7 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com