Tool and method for removing steam sealing block used for steam turbine generator unit

A technology for a steam turbine generator set and a dismantling tool, which is applied in the field of steam turbines, can solve the problems of difficult dismantling, time-consuming dismantling, and great potential safety hazards, and achieves the effects of convenient and rapid dismantling, high dismantling efficiency, and not easy to be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

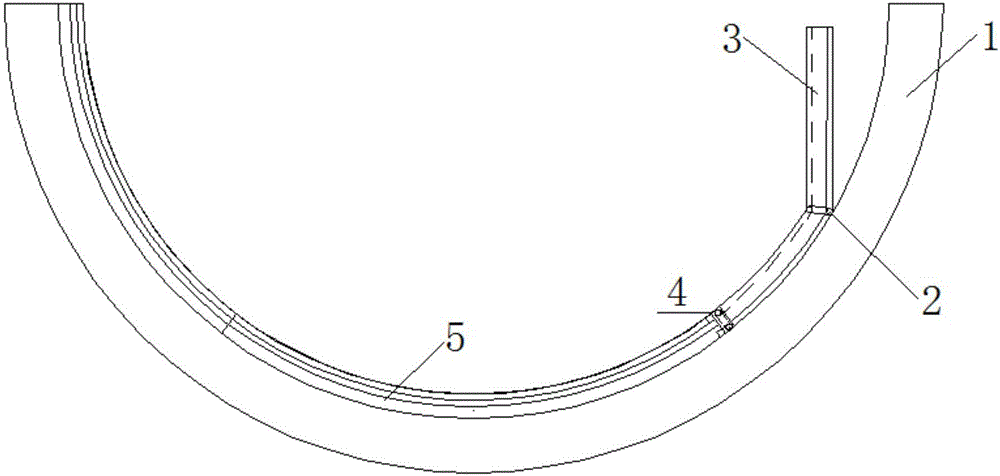

[0030] Such as figure 1 As shown, under normal circumstances, the gland cover 1 is fixed with three gland blocks 5, after removing the first gland block, use the removal tool for the steam seal block of the steam turbine generator set for the second gland block in the middle , the removal tool includes a push rod with the same arc of 5 degrees as the steam seal block. One end of the push rod is provided with a metal pad that engages with the end of the steam seal block. The metal pad is less than the hardness of the steam seal block to avoid damage to the steam seal block. , the metal pad cooperates with the end of the steam seal block 5, and the steam seal block is pushed by pushing the push rod, and then the steam seal block is removed, which is simple and convenient.

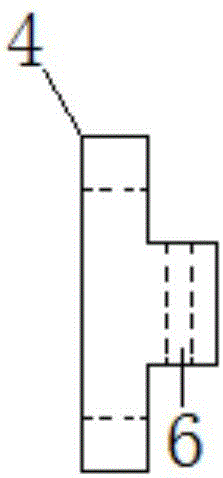

[0031] The push rod consists of two sections, the first section fixed to the metal pad has the same arc as the steam seal block, the second section is vertically connected to the first section, the angle form...

Embodiment 2

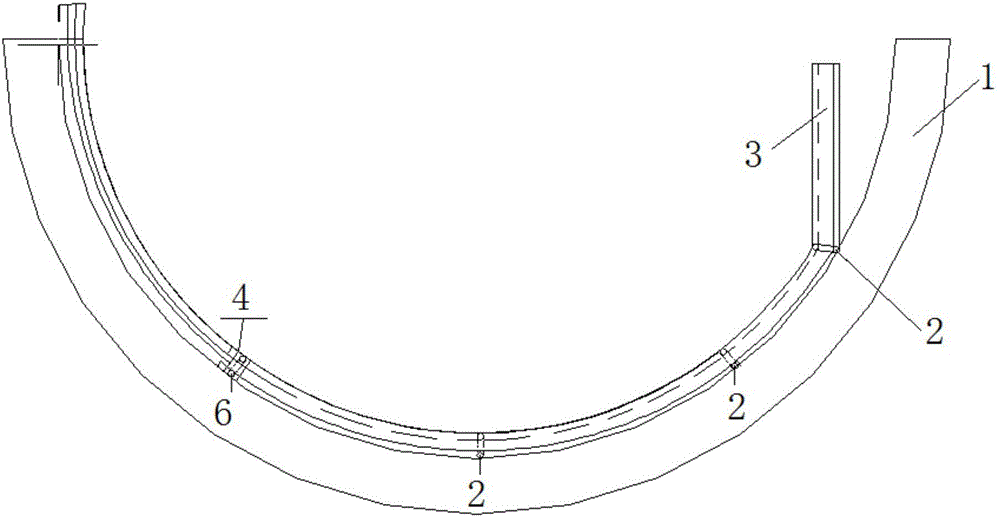

[0037] Such as figure 2 As shown, the push rod includes the first section and the second section, the first section has multiple sections, and the two adjacent sections of the push rod are connected by the first pin shaft, and the arc of the first section of the push rod and the steam seal block are the same To fit with the steam seal sleeve. In this way, after removing the middle steam seal block in Example 1, for the third steam seal block, by knocking the top of the second section of the push rod, the end of the steam seal block in contact with the non-copper gasket is knocked out of the steam seal sleeve. The end of the exposed steam seal block of the steam seal sleeve can quickly realize the rapid removal of the third steam seal block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com