Preparation method of high-strength air filter paper

An air filter paper, high-strength technology, applied in pulp beating method, filter paper, separation method, etc., can solve the problems of cumbersome air filter paper production process, reduce the service life of air filter paper, affect the processing of papermaking raw materials, etc. Good, easy to process, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

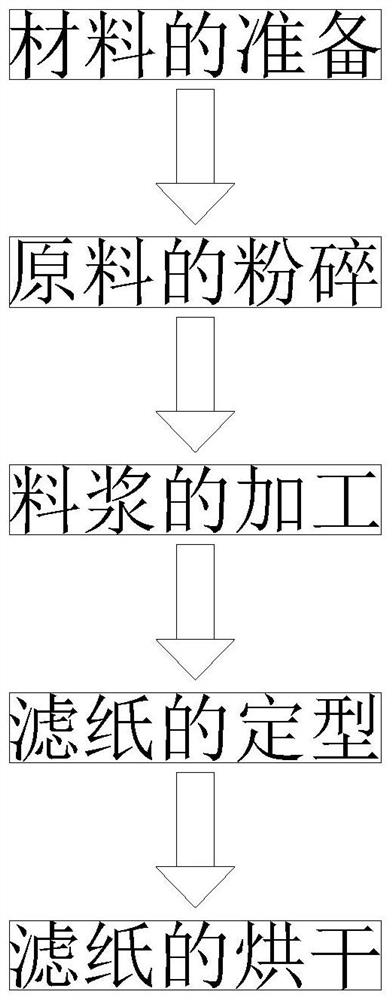

[0046] like Figure 1-5 As shown, the present invention provides a preparation method of high-strength air filter paper, and the preparation method of the air filter paper comprises the following steps:

[0047] Step 1: Preparation of materials;

[0048] Step 2: Crushing of raw materials;

[0049] Step 3: Processing of slurry;

[0050] Step 4: Setting the filter paper;

[0051] Step 5: Drying of filter paper.

[0052] Step 1 also includes the following steps:

[0053] A1: Prepare glass fiber materials, carbon nanomaterials, liquid binders, active additives, flame retardant mixtures, and antibacterial coatings for making air filter paper;

[0054] A2: Prepare the mechanical processing equipment needed to make air filter paper.

[0055] Step 2 also includes the following steps:

[0056] B1: Put the glass fiber material and carbon nanomaterial as the main materials into the prepared crushing device;

[0057] B2: The material is pulverized by the pulverizing device to impr...

Embodiment 2

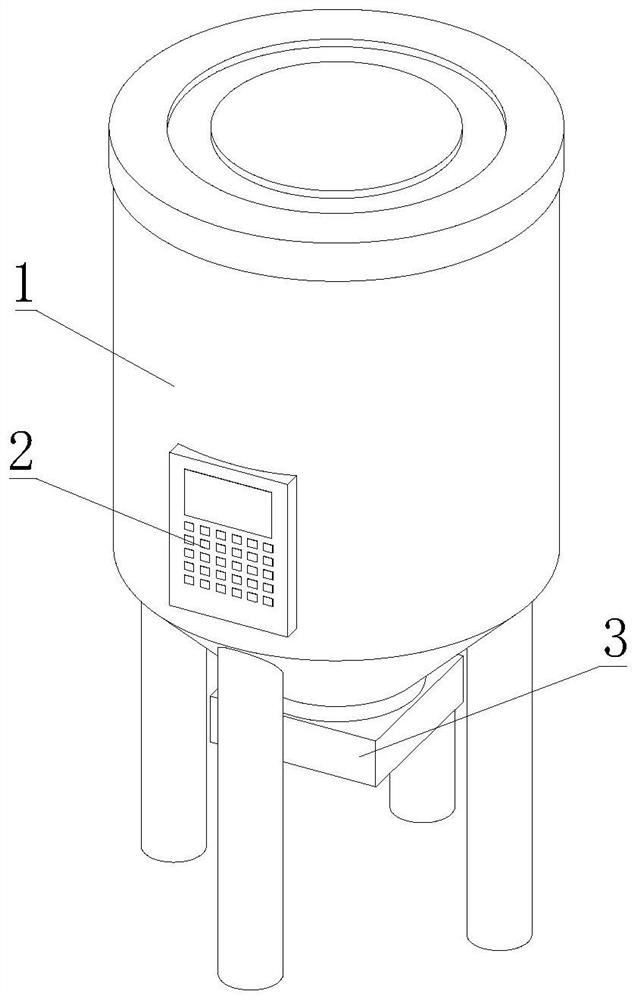

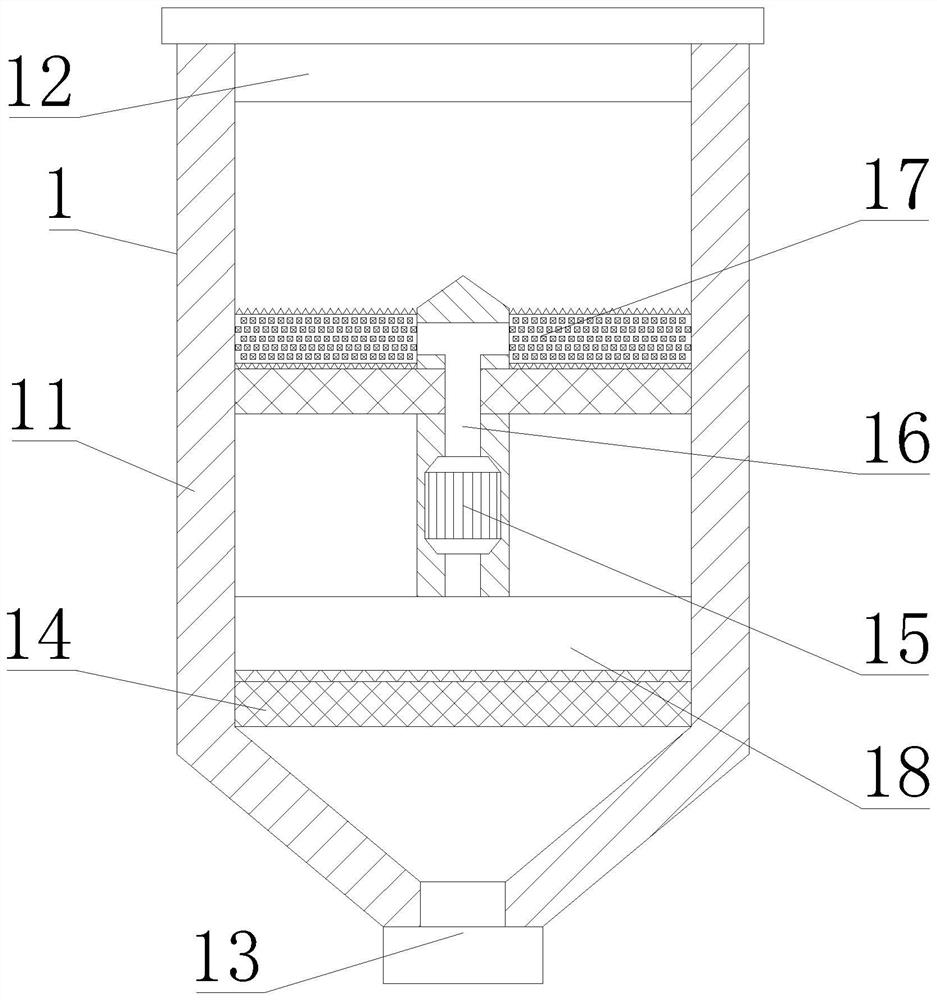

[0070] like Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the pulverizing device includes a pulverizing mechanism 1, a console 2 and an anti-blocking mechanism 3, and the console 2 is fixedly connected to the front end of the pulverizing mechanism 1, The anti-blocking mechanism 3 is fixedly connected to the bottom end of the crushing mechanism 1. The crushing mechanism 1 includes a crushing barrel 11. The top of the crushing barrel 11 is provided with a barrel cover 12, and the bottom end of the crushing barrel 11 is fixedly connected with a discharge pipe 13. The discharge pipe 13 is arranged on the top of the anti-blocking mechanism 3, the inside of the pulverizing bucket 11 is fixedly connected with a filter screen 14, the inside of the pulverizing bucket 11 is fixedly connected with a first motor 15, and the output shaft of the first motor 15 is fixedly connected with a rotating rod 16, which rotates. T...

Embodiment 3

[0073] like Figure 1-5 As shown, on the basis of Embodiment 2, the present invention provides a technical solution: preferably, the pulverizing plate 18 includes a rotating plate 181, the rotating plate 181 is fixedly connected to the bottom end of the rotating rod 16, and the bottom end of the rotating plate 181 is fixed The pulverizing teeth 182 are connected, the inner two sides of the rotating disc 181 are movably connected with a driving wheel 183, the side of the driving wheel 183 is meshed and connected with a gear ring 184, and the gear ring 184 is fixedly connected with the inner wall of the pulverizing bucket 11. The bottom end of the driving wheel 183 A rotating block 185 is fixedly connected, a moving rod 186 is movably connected to the side of the rotating block 185 , one end of the moving rod 186 is movably connected with a movable pressing block 187 , and the movable pressing block 187 is movably connected to the inner bottom end of the rotating disk 181 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com