Electric vehicle charging pile manipulator control method

A control method and a technology of a manipulator, applied in manipulators, manufacturing tools, etc., can solve the problems of increased human workload, difficulty in centralized charging, high construction and maintenance costs of charging stations, and achieve the effect of ensuring running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The concrete implementation method of the present invention is as follows:

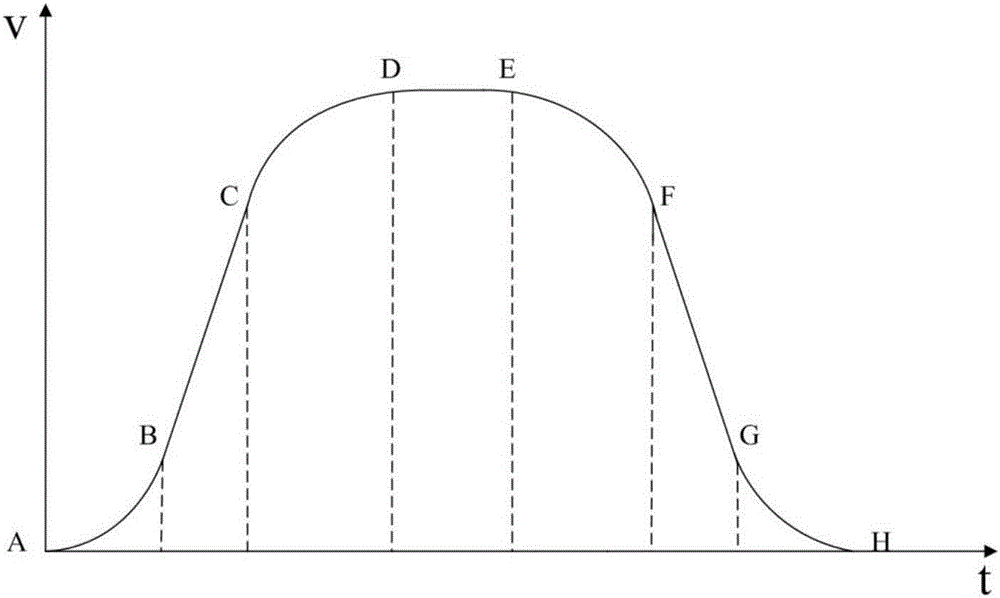

[0022] like figure 1 Shown is a schematic diagram of the time-speed relationship of the control method of the electric vehicle charging pile mechanical arm of the present invention, wherein point A to point H is the whole process of one operation, and the whole process shown is divided into AB, BC, CD, DE, There are seven intervals of EF, FG, and GH, and the displacement ratio of each interval segment remains unchanged.

[0023] After determining the operating position and displacement of the shown manipulator, the corresponding displacement of each section is obtained according to the ratio of the seven sections shown, and then the operation of the shown manipulator is controlled according to the operation mode of each section, and the manipulator is monitored in real time The running displacement or remaining displacement is used to determine the moment when the shown robot arm turns to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com