Automatic injection-molding part runner cutting equipment

A technology for injection molded parts and water cutouts, which is applied in the field of automatic water cutout equipment for injection molded parts. It can solve the problems of low efficiency, damage to the workpiece, time-consuming and labor-intensive problems, so as to reduce labor intensity, ensure the accuracy of positioning, and operate simply and conveniently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

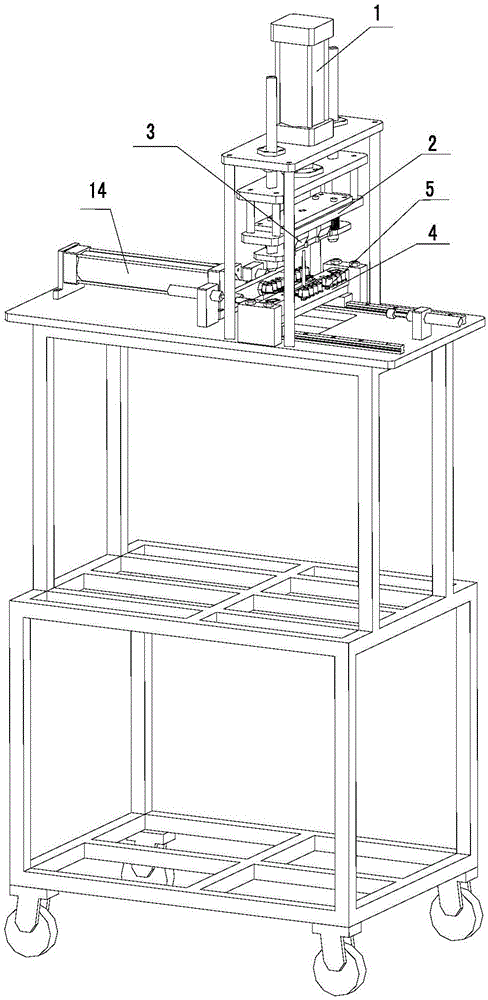

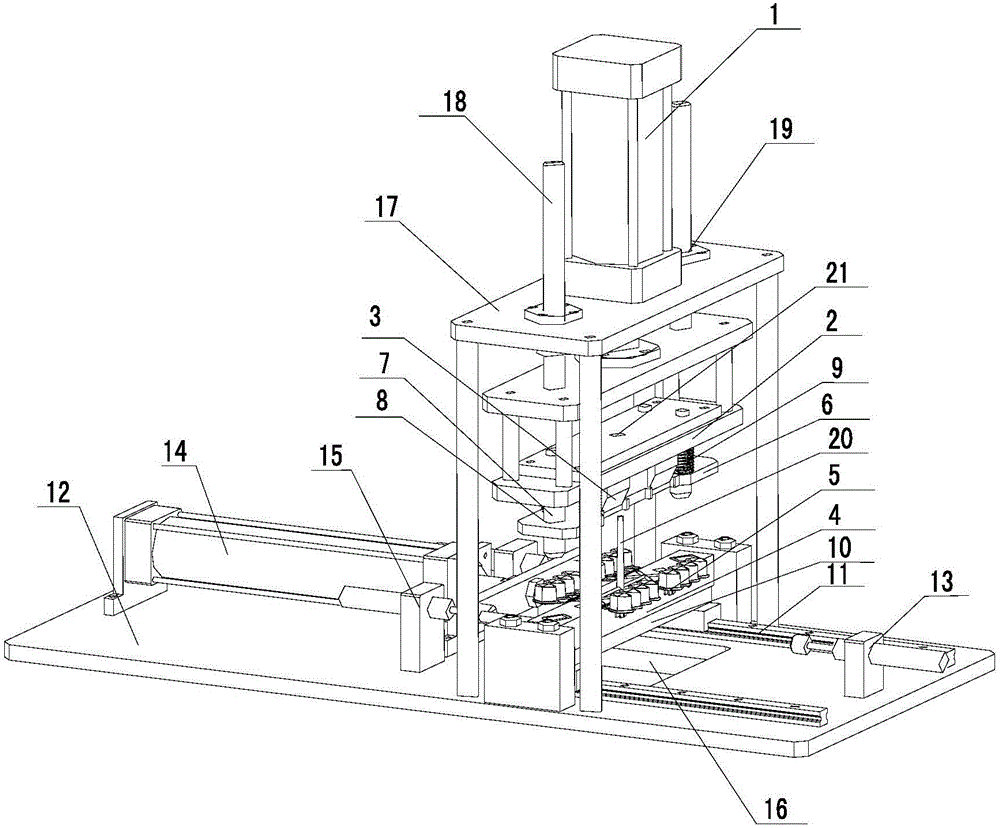

[0024] The invention provides an automatic water cutting device for injection molded parts, such as Figure 1-2 As shown, it includes: an upper mold that can move up and down under the drive of the first cylinder 1 and a lower mold that cooperates with the upper mold. The upper mold includes a pressing plate 2 and a cutting knife 3 arranged below the pressing plate 2. The lower mold It includes a bottom plate 4 and a bottom punch 5 fixedly connected to the bottom plate 4 for fixing the injection molded part. The shape of the cutting knife 3 is adapted to the outer contour of the part to be cut on the injection molded part.

[0025] Driven by the driving shaft of the first cylinder 1, the upper mold is cut from top to bottom along the outer contour of the part to be cut on the injection molded part, and the flow channel part of the injection molded part is completely peeled off at one time, and cut off by the first cylinder. The knife separation nozzle replaces the manual separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com