Automated inkjet printing plate-making equipment

An inkjet printing and equipment technology, applied in the field of automatic inkjet printing plate-making equipment, can solve the problems of slow printing speed and irregular paper arrangement, and achieve the effect of fast printing speed, neat paper arrangement and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

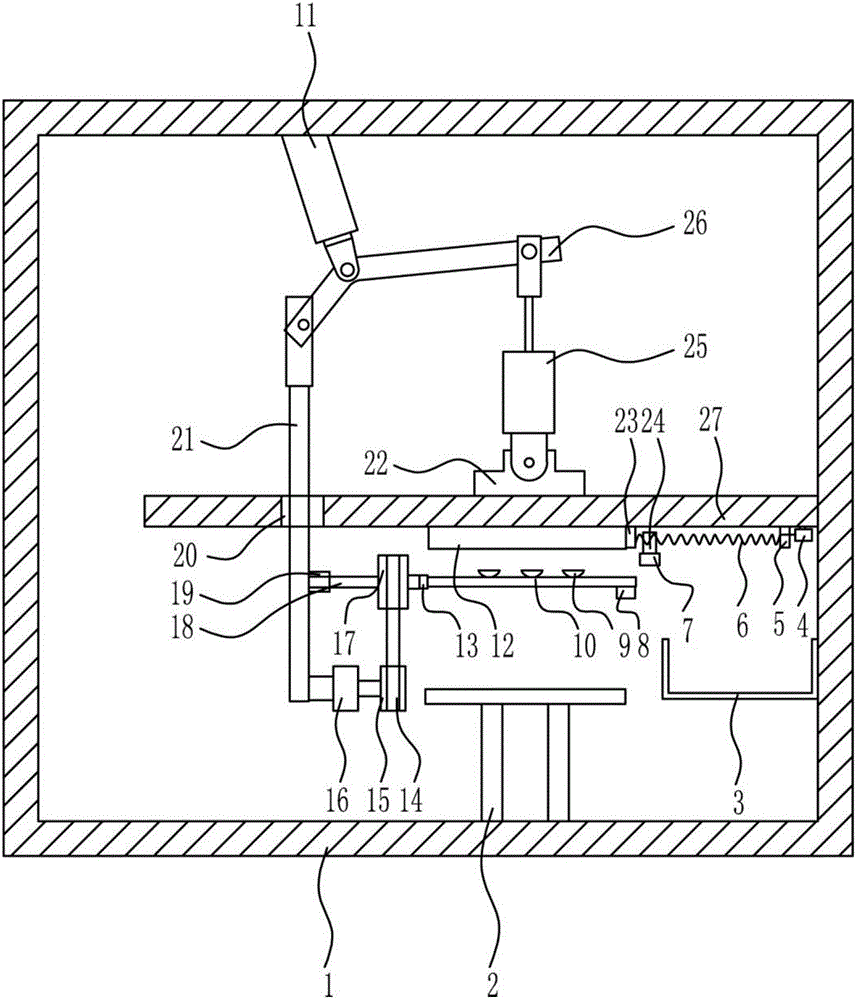

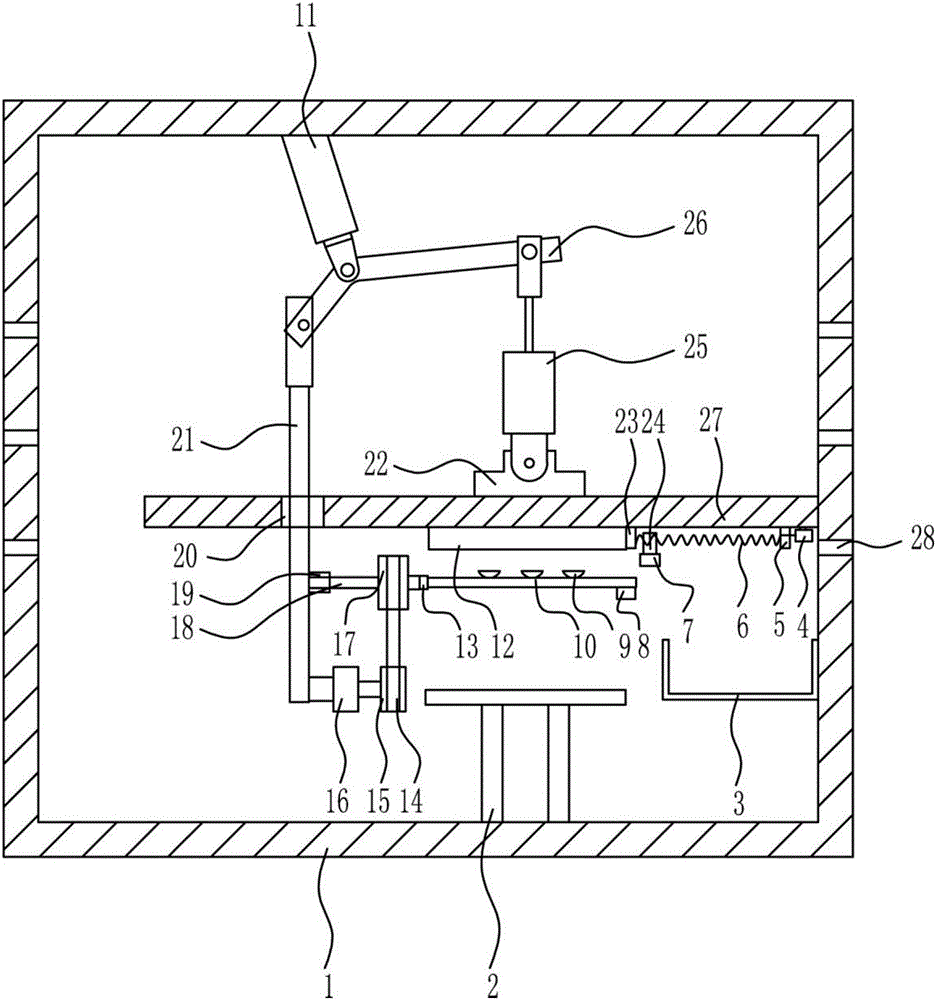

[0028] An automatic inkjet printing plate making equipment, such as Figure 1-4 As shown, it includes a box body 1, a placement table 2, a collection tank 3, a first motor 4, a right bearing seat 5, a screw rod 6, a first electromagnet 7, a second electromagnet 8, an iron fixing plate 9, an electric motor Suction cup 10, first bearing seat 11, special printing nozzle 12, third electromagnet 13, flat belt 14, driving wheel 15, second motor 16, driven wheel 17, rotating shaft 18, second bearing seat 19, lifting rod 21, Swing seat 22, left bearing seat 23, nut 24, electric push rod 25 and curved rod 26; A guide plate 27 is arranged on the inner right wall of the box body 1, and the left end of the guide plate 27 is provided with a first hole 20, and the top of the guide plate 27 The right side is provided with a swing seat 22, the swing seat 22 is provided with an electric push rod 25, the bottom of the box body 1 is provided with a first bearing seat 11, and the bottom end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com