Intelligent material picking and releasing device of combing machine

A pick-and-place device and combing machine technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of high labor intensity and low work efficiency, and achieve improved operating efficiency, simple structure, and reduced downtime Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

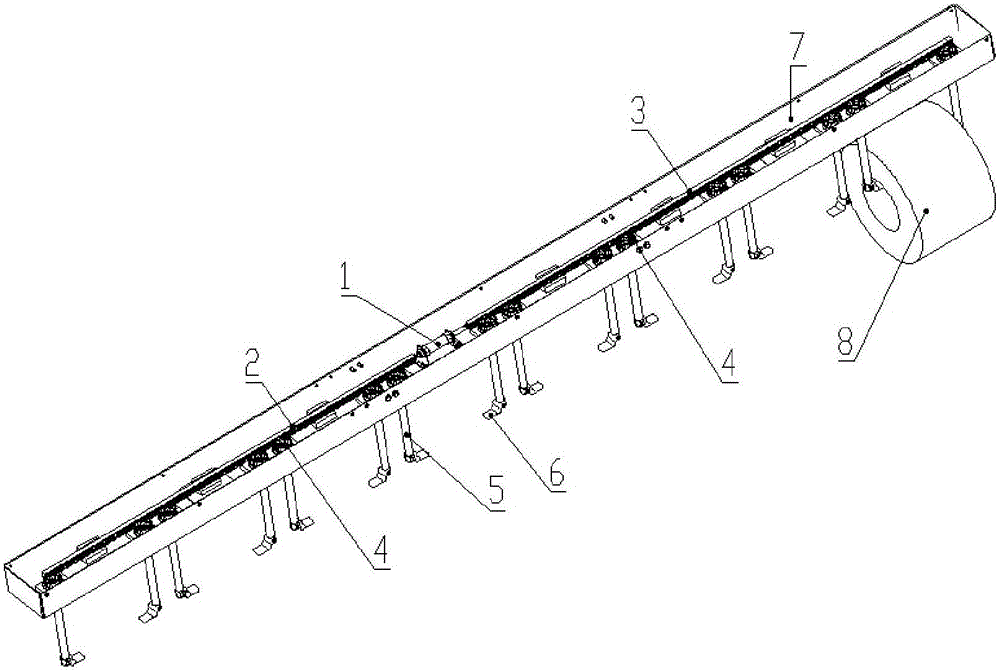

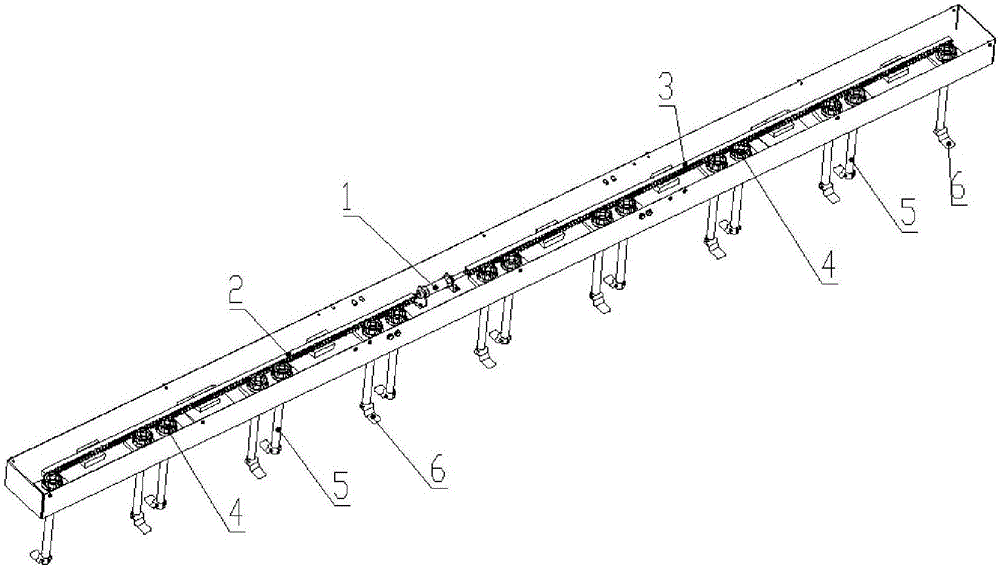

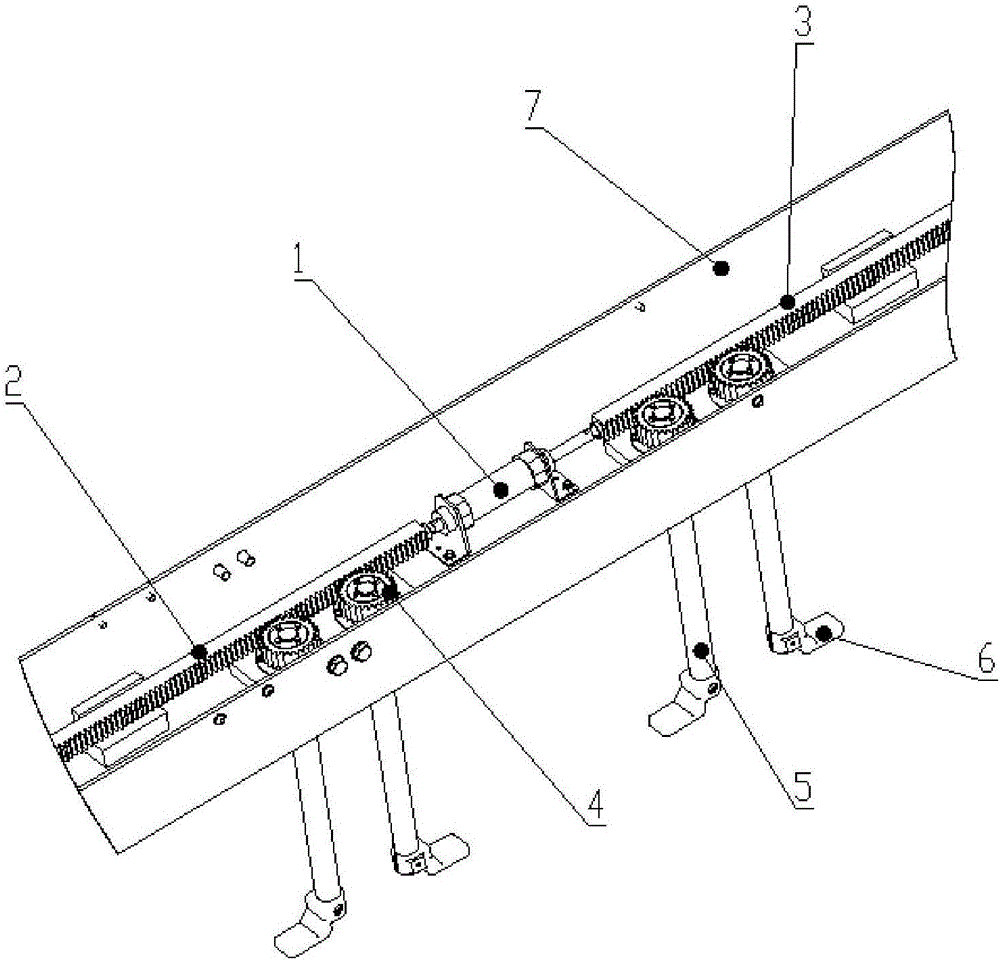

[0017] Embodiment: an intelligent combing machine material pick-and-place device, including a support frame 7, a pull rod 5, a gripper 6, a transmission mechanism and a driving device, and the plurality of pull rods 5 are rotatably positioned on the support frame 7, and each pull rod 5 Arranged at intervals along the length direction of the support frame 7, two adjacent tie rods 5 form a group, the gripper 6 is fixedly installed on the lower end of the tie rods 5, the gripper 6 extends in a direction perpendicular to the axial direction of the tie rods 5, and the driving device is driven by a transmission mechanism Each pull rod 5 rotates. When the electrical control unit sends a signal to grab the cotton roll 8 or bobbin, the driving device drives the pull rod 5 and the gripper 6 to rotate through the transmission mechanism, so that the gripper 6 rotates 90° to reach a position parallel to the material. The direction of the length direction of the pick-and-place device, each g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com