Water hammer impact wave pulsation system applied to ship ballast water treatment

A technology of ship ballast water and pulsation system, which is applied in the direction of water treatment under pressure conditions, water/sewage treatment, natural water treatment, etc., and can solve the problem of water bulkhead surface or structural damage, unsatisfactory treatment effect, weak penetration, etc. Problems, to achieve significant disinfection and sterilization treatment effect, low cost, simple device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

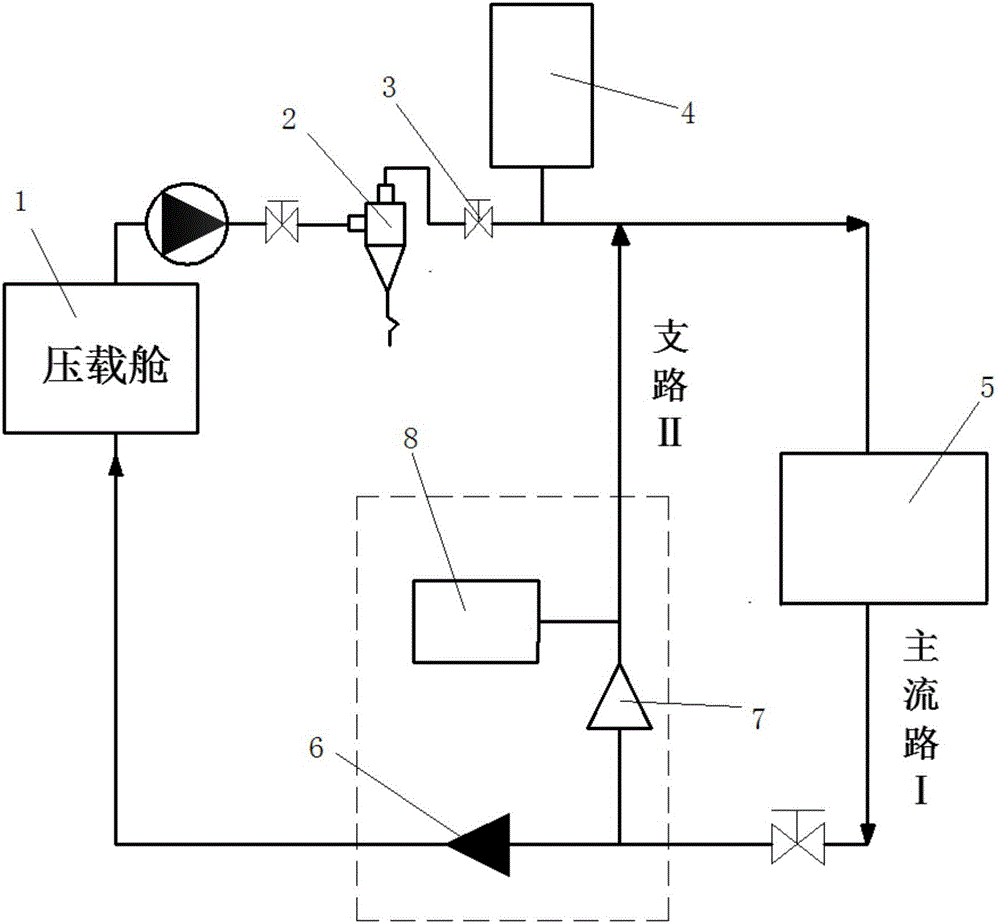

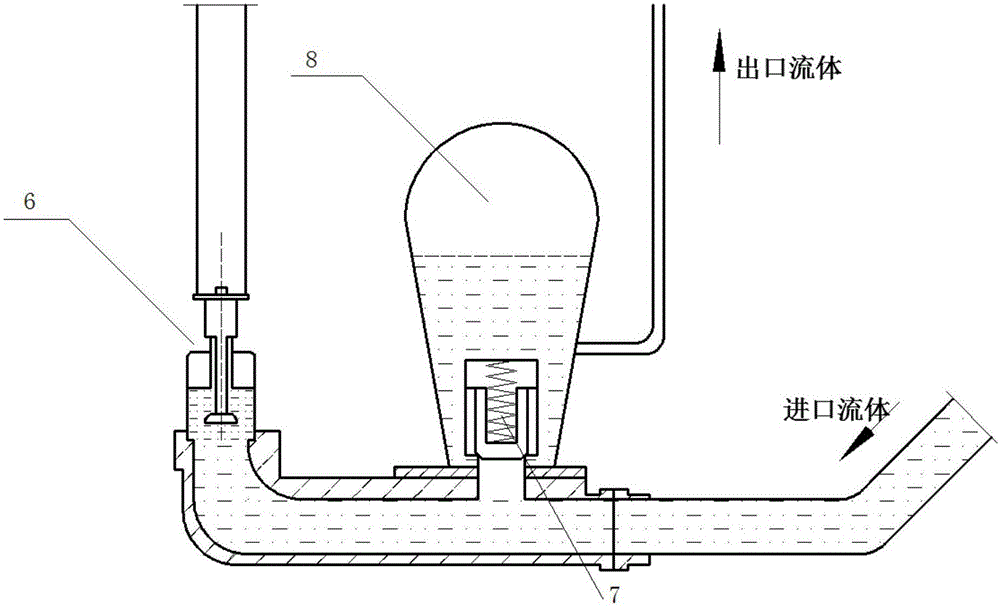

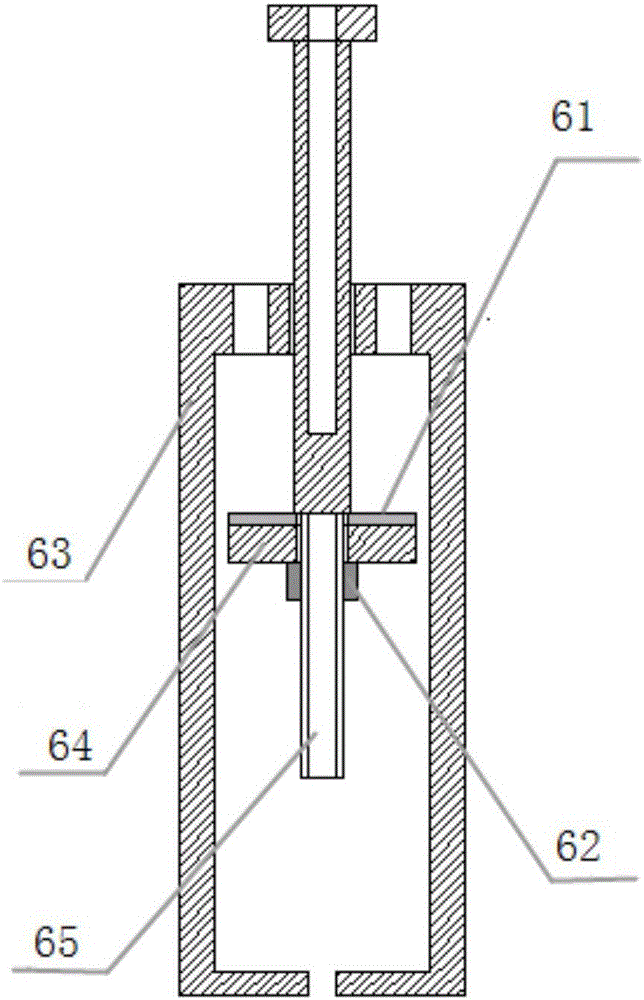

[0021] Such as Figure 1 to Figure 4 As shown, the water hammer shock wave pulsation system applied to ship ballast water treatment of the present invention includes a ballast tank 1 and a treatment chamber 5, and the ballast tank 1 passes through a centrifugal pump, a cyclone separator 2, and a regulating valve 3 in sequence. 1. The second energy storage tank 4 is connected to the inlet of the processing chamber 5, the outlet of the processing chamber 5 is connected to the ballast tank 1 through the impact valve 6, and the other outlet of the processing chamber 5 is connected to the spring check valve 7 and the first energy storage tank 8. The inlet of the processing chamber 5 is connected, the material of the first energy storage tank 8 is stainless steel or plastic material, and the shape is a cuboid or column; the water in the ballast tank 1 passes through the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com