Heat-insulating method used during hot maintenance of coke oven carbonization room

A technology of carbonization chamber and coke oven, which is applied in the direction of preventing/repairing bricklaying leakage, etc. It can solve the problems of lax shielding, tearing, poor heat insulation effect, etc., so as to save maintenance cost, shorten maintenance cycle and fast installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] The steps of thermal repair and heat insulation method for coke oven carbonization chamber are as follows:

[0028] Step 1. Preliminary preparation.

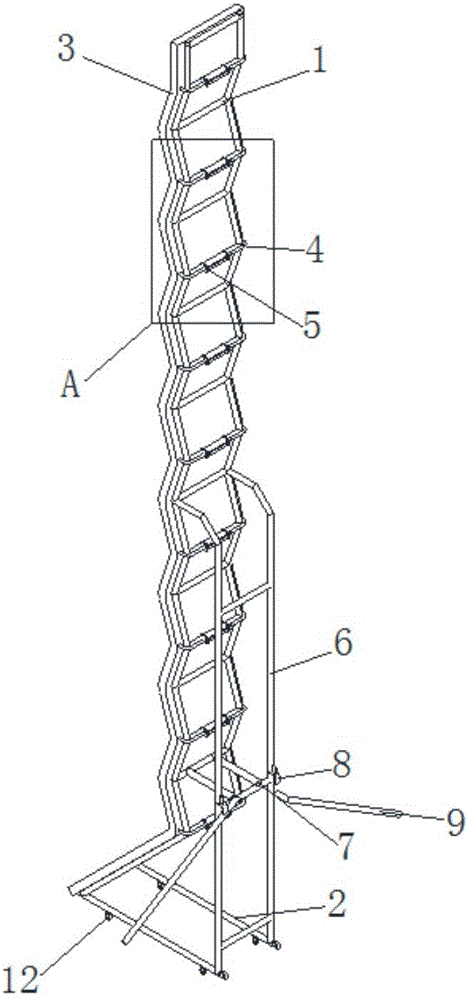

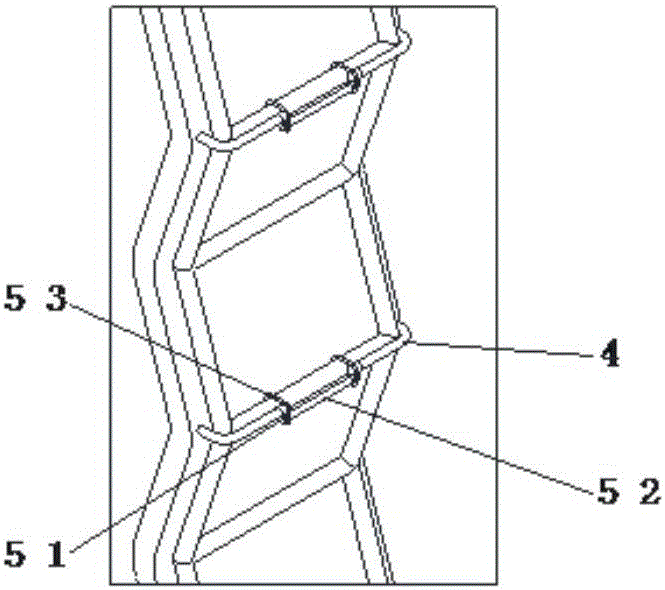

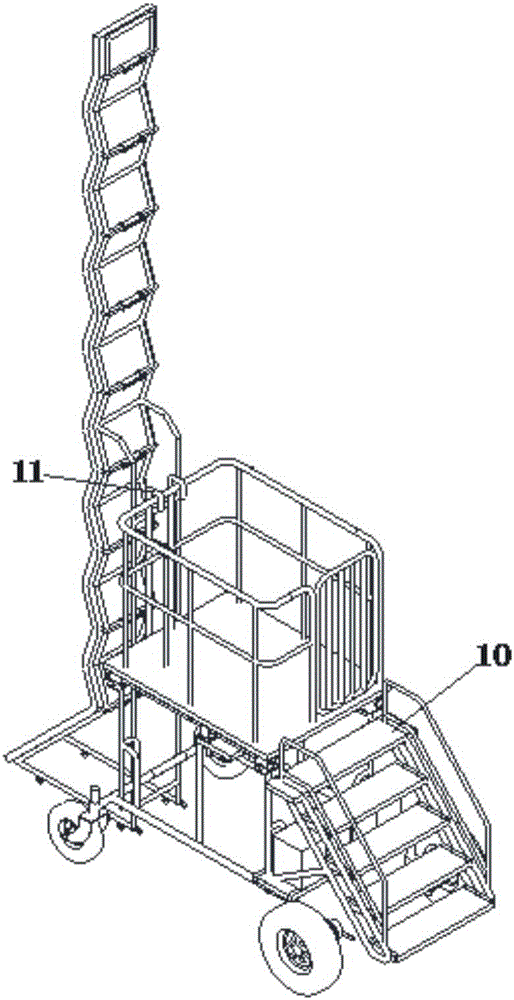

[0029] Lay the whole roll of ceramic fiber felt on the wave frame of the thermal repair heat insulation protection screen of the coke oven carbonization chamber. 1200℃ objects can be insulated by about 110℃ after being painted with paint, objects at 500℃ can be insulated by about 40℃ after being painted with paint, and objects at 200℃ can be insulated by about 15℃ after being painted with paint), at the peak of the wave structure The ceramic fiber rope 4 is used to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com