Bridge sling wire sealing protection structure and protection method

A technology for steel wire slings and protective structures, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of reduced anti-corrosion performance, low strength of the protective layer, and cracks in the protective layer, so as to save maintenance costs and improve compatibility , the effect of preventing steel wire corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

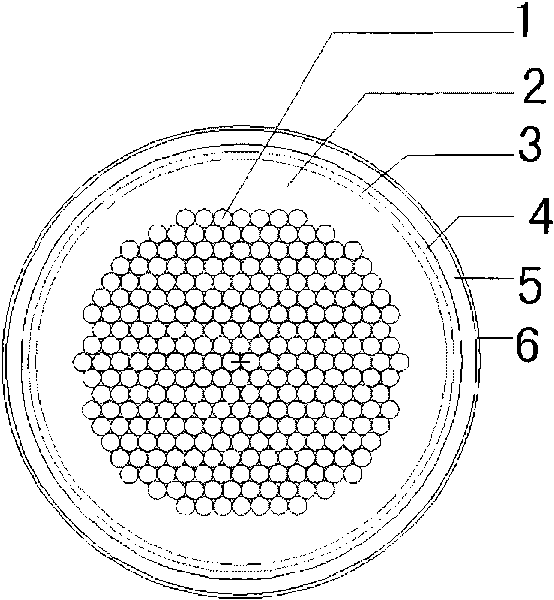

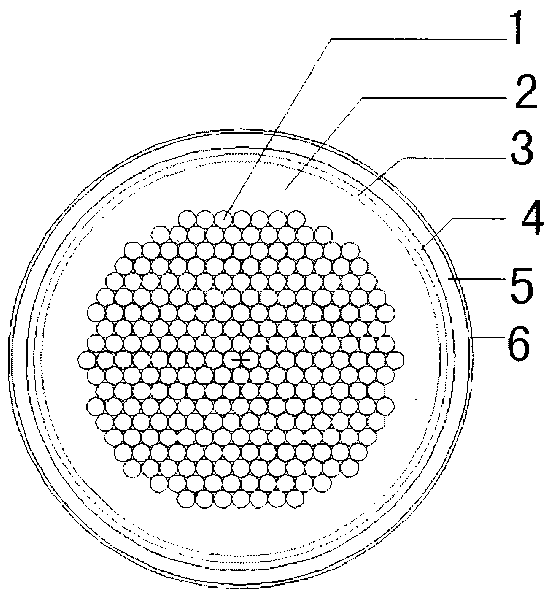

[0021] 1) The surface of the polyethylene sheath 2 or the sling 1 (bare part) of the steel wire rope sling of the present invention is routinely cleaned, after removing the rust and dirt on the surface, the outer surface is scraped and coated with a layer of elastic room temperature vulcanized polysulfide sealant (HM106 produced by Beijing Aeronautical Materials Research Institute of China Aviation Industry Corporation), the scraping thickness of the sealant is 1500μm;

[0022] 2) After scraping the room temperature vulcanizing sealant, before the sealant is vulcanized, wrap a neutral plain glass cloth with a thickness of 0.2mm. The glass cloth is wound by 50% overlap, and the thickness of the glass cloth after winding is 500 μm;

[0023] 3) Brush the room temperature vulcanized polysulfide sealant on the outside of the neutral plain glass cloth again. The sealant is first diluted with ethyl acetate, and the dilution concentration is 70%. The thickness of the brushed sealant ...

Embodiment 2

[0026] 1) routine cleaning is carried out to the surface of the polyethylene sheath 2 of the steel wire rope sling or the sling 1 (bare part), after removing the rust and dirt on the surface, the outer surface is scraped and coated with a layer of elastic room temperature vulcanized polyurethane sealant ( The polyurethane sealant of GF-3-Z9 produced by Shanxi Provincial Institute of Chemical Industry), the scraping thickness of the sealant is 2000 μm;

[0027] 2) After scraping the room temperature vulcanizing sealant, before the sealant is vulcanized, wrap a neutral plain glass cloth with a thickness of 0.15mm. The glass cloth is wound by 50% overlap, and the thickness of the glass cloth after winding is 1000μm;

[0028] 3) Scrape again the room temperature vulcanized polyurethane sealant outside the neutral plain glass cloth, the thickness of the sealant is 2000μm;

[0029] 4) After the room temperature vulcanization polysulfide sealant is vulcanized, brush the acrylic poly...

Embodiment 3

[0031] 1) The surface of the polyethylene sheath 2 or the sling 1 (bare part) of the steel wire rope sling of the present invention is routinely cleaned, after removing the rust and dirt on the surface, the outer surface is scraped and coated with a layer of elastic room temperature vulcanized silicone sealant (HM304 produced by Beijing Aeronautical Materials Research Institute of China Aviation Industry Corporation), the scraping thickness of the sealant is 1000 μm;

[0032] 2) After scraping the room temperature vulcanizing sealant, before the sealant is vulcanized, wrap a neutral plain glass cloth with a thickness of 0.2mm. The glass cloth is wound by 50% overlap, and the thickness of the chemical fiber cloth after winding is 2000μm;

[0033] 3) Scratch-coat room temperature vulcanized silicone sealant on the outside of the neutral plain glass cloth again, and the thickness of the sealant to be scraped is 500 μm;

[0034] 4) After the room temperature vulcanization polysul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com