Preparation method of dissolved oxygen sensing film

A technology of sensing film and dissolved oxygen, which is applied in measuring devices, instruments, fluorescence/phosphorescence, etc., can solve problems such as leakage and reduce the optical characteristics of indicators, and achieve the effects of reducing maintenance cycles, ensuring optics, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

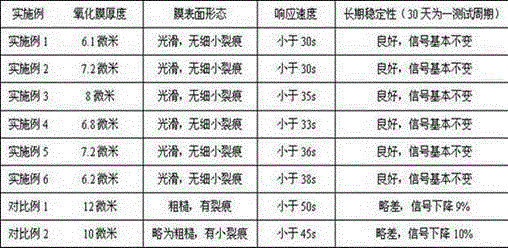

Examples

Embodiment 1

[0025] Put 1 volume of tetraethoxysilane and 1 volume of trifluoromethyltrimethoxysilane into the reaction kettle, add 0.2 volumes of water and 2 volumes of a mixed solution of propanol and butanol, add maleic acid, and control the pH range to 1.0, sealed and stirred for 3 hours, added 0.5 volume of tris(2,2′-bipyridine) ruthenium (II) complex propanol solution, ultrasonically dispersed for 20 minutes, and aged in a dark room for 24 hours.

[0026] At 25°C, the oil phase and the water phase with a mass ratio of 12:88 were mixed with magnetic stirring to form a microemulsion. The components of the oil phase are AOT, Triton and decane, and the components of the water phase are acrylamide, sodium acrylate and tris(2,2'-bipyridine) ruthenium (II) complex. After the microemulsion is formed, the particle size of the emulsion is controlled at 20nm, and then an appropriate amount of initiator solution (a mixed aqueous solution of potassium persulfate and sodium bisulfite, the concentr...

Embodiment 2

[0030] Put 1 volume of tetraethoxysilane and 1 volume of trifluoromethyltrimethoxysilane into the reaction kettle, add 0.2 volumes of water and 2 volumes of propanol-butanol mixed solution, add succinic acid, control the pH range to 2.0, seal and stir After 1 hour, add 0.5 volume of tris(5-amino-1,10-phenanthroline) ruthenium propanol solution, ultrasonically disperse for 10 minutes, and put it in a dark room for aging for 48 hours.

[0031] At 25°C, the oil phase and the water phase with a mass ratio of 16:84 are mixed with magnetic stirring to form a microemulsion. The oil phase components are AOT, Triton, and decane, and the water phase is composed of acrylamide and sodium acrylate. And three (5-amino-1,10-phenanthroline) ruthenium (Ⅱ) complexes. After the microemulsion is formed, the particle size of the emulsion is controlled at 50nm, and then an appropriate amount of initiator solution (mixed aqueous solution of potassium persulfate and sodium bisulfite, with a concentra...

Embodiment 3

[0035] Put 1 volume of tetraethoxysilane and 1 volume of trifluoromethyltrimethoxysilane into the reaction kettle, add 0.2 volumes of water and 2 volumes of propanol-butanol mixed solution, add benzenesulfonic acid derivatives, and control the pH range to 1.8 , sealed and stirred for 2.5 hours, added 0.5 volume of tris(4,7-diphenyl-1,10-phenanthroline) ruthenium (II) complex propanol solution, ultrasonically dispersed for 20 minutes, and put it in a light-proof room for aging 36h.

[0036] At 50°C, the oil phase and the water phase with a mass ratio of 20:80 are mixed with magnetic stirring to form a microemulsion, in which the oil phase components are AOT, Triton, and decane, and the water phase components are acrylamide and sodium acrylate. And three (4,7-diphenyl-1,10-phenanthroline) ruthenium (Ⅱ) complexes. After the microemulsion is formed, the particle size of the emulsion is controlled at 40nm, and then an appropriate amount of initiator solution (mixed aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com