Anti-collision bar with elastic material layer for automobile body

A technology of elastic material layer and automobile body, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of complex processing technology of anti-collision strips and poor anti-collision effect, and achieve lower product quality, good impact resistance effect, good The effect of absorbing impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention are now described in detail.

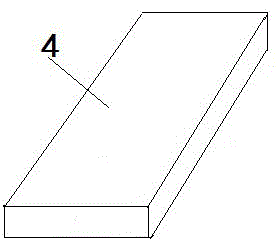

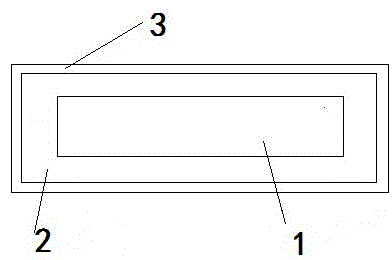

[0023] like figure 1 and figure 2 Shown is an anti-collision strip 4 for an automobile body, the core of which is a particle-reinforced foamed aluminum-based composite material 1, the core is surrounded by an elastic material layer 2, and the outer layer of the elastic material is a rectangular steel pipe 3.

[0024] An anti-collision strip for an automobile body, the core of which is a particle-reinforced foamed aluminum-based composite material, the core is wrapped with an elastic material layer, and the outer layer of the elastic material is a rectangular steel pipe, which is characterized in that:

[0025] The particle-reinforced foamed aluminum-based composite material is prepared by the following preparation method:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com