Improved yarn coating machine and operation method thereof

An operation method and technology of a coating machine are applied in the field of coating machines and improved yarn coating machines, which can solve the problems of cumbersome operation, reduce work efficiency, and increase the amount of cumbersome work, so as to avoid pulling damage and have a simple structure. , the effect of reducing the amount of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

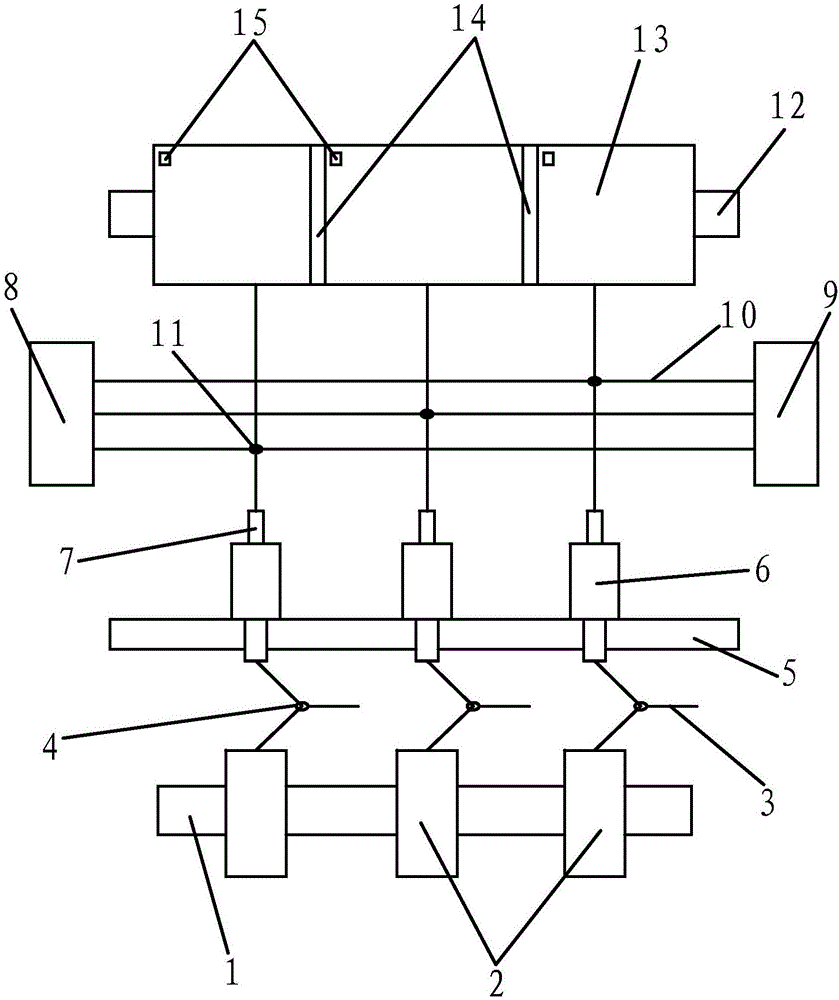

[0022] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0023] Such as figure 1 As shown, the improved yarn covering machine includes a spandex roller 1, a number of spandex rolls 2 are sleeved on the spandex roller 1, and a plurality of yarn covering mechanisms are arranged above the spandex roller 1, and the covering mechanism is formed with the spandex roll 2. One-to-one corresponding arrangement, the yarn wrapping mechanism includes a yarn tube 7 and a yarn wrapping spindle 6 that drives the yarn tube 7 to rotate. The lower part of the yarn wrapping spindle 6 is connected with a transmission mechanism. A tension assembly is arranged between the yarn wrapping spindle 6 and the spandex roll 2. A winding roller 12 is arranged above the yarn mechanism, and the winding roller 13 is sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com